what is the soybean extraction in lesotho

- Usage: Soybean Oil

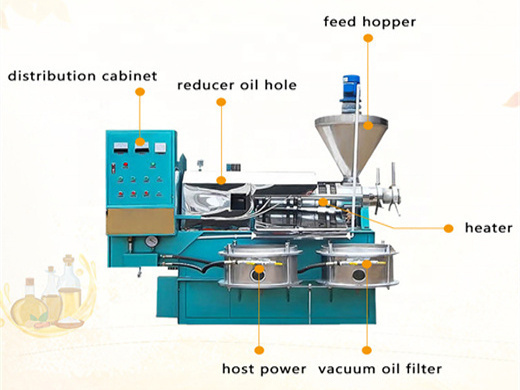

- Type: Cold & Hot Pressing Machine, soybean cake oil extraction machine

- Production Capacity: 30TPD-1000TPD

- Model Number: 6YY-260

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008

- Color: Silver

- Production condition: One staff, plant 10㎡

- Material: Carbon steel, stainless steel

- Raw material: Soybean Seed

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical operating

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Industrial relevance. Typically, the extraction of protein from an intermediate soy-protein ingredient is studied at lab-scale. Within industry, aqueous extract from whole soybeans is commonly used for making consumer products containing both soy protein and soybean oil, and this has been the focus of this review.

The conventional soybean extraction process consists of four steps; preparation, extraction, solvent recovery from miscella and desolventizing/toasting of meal. Modern soybean processing involves large plants with many operations that must be considered. Transportation, material handling, drying, and milling are similar to other grain processing.

Overview of the soybean process in the crushing industry

- Usage: Soybean seeds,Soybean processing machine

- Type: Soybean seeds,Soybeanprocessing machine

- Production Capacity: 30kg-30t/day

- Model Number: oil press machine for sale

- Voltage: 380V or designed by your needs

- Power(W): Depend on the machine you choose

- Dimension(L*W*H): Depend on the machine you choose

- Weight: Depend on the machine you choose

- Certification: CE and ISO

- Item: Soybean oil pressing making machine

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Steel type: MiId steel and SS

- Raw materials: Soybean seeds,Soybean

- Fina product: Salad oil

- Processing method: Machanical press

- Handling capacity: 5-20MT Soybean oil press machine for sale

- Model type: Continuous

- Main market: Africa, Aisa

Abstract. A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusher. In a modern and efficient extraction plant, a residual oil content ≤ 0.5% for soybean meal is expected.

In this guide to soybean processing, we examine the history of this seed’s production, processing methods, and product applications as we explore its global market growth potential. Today, the top soybean-producing countries include Brazil (144 MMT), US (120 MMT), Argentina, and China. Soybeans contain enzymes that can be toxic to humans and.

Profitability Analysis of Soybean Oil Processes - PMC

- Usage: Soybean Oil;

- Production Capacity: 100%, 99%

- Model Number: HT-POM

- Voltage: 380V

- Power(W): 3-15KW

- Dimension(L*W*H): according to the specification

- Weight: 35ton

- Certification: ISO9001,CE,BV

- type: Soybean oil refined machine

- Raw materials: Soybean, cutton seed

- Material of equipment: stainless steel and carbon steel

- including: machines,installation,tech consulting after sales

- operattion: automatic and safe

- Capacity: 1T to 500T

- color: according to your need

- Warranty period: 1 year

In the profitability analysis of the soybean oil extraction process, the total capital investments of extruding-expelling process, hexane extraction, and EAEP are 26.6, 41.0, and 7.6 million dollars (2015 price) based on 30.8, 22.4, and 0.1 million kg of annual soybean oil production respectively. The different scales of production are also.

The defatted soybean flakes that remain after the extraction of the oil and solvent is toasted and ground into soybean meal containing approximately 44% protein. Removal of the soybean’s hull prior to processing produces approximately 48% protein soybean meal, and is referred to as dehulled soybean meal (DHSBM). The

Soybean Extract - an overview | ScienceDirect Topics

- Model Number: JN-30

- Usage: dry and sterilization

- Type: Microwave

- Voltage: 380V/220V

- Power(W): 30kw

- Weight: 800kg

- Dimension(L*W*H): 4938mm*1600mm*1880mm

- Certification: CE ISO

- Warranty: 1 Year

- name: Soybean meat Microwave drying sterilization machine

- usage: drying and sterilizing

- model: JN-30

- power input: 42KVA

- power output: 30KW

- temperature: 0~200C(adjustable)

- transmission speed: 0~10m/min

- material: stainless steel

- delivery time: in 25 work days

Soybean extracts are popularly known as nutritional and medicinal ingredients. ) is legume species native to East Asia. are popularly known as nutritional and medicinal ingredients. The functional constituents of soybean include flavonoids, isoflavonoids, tannins, phenolic acids and proanthocyanidins.

Aqueous extraction processing technologies, having advanced in recent years, may be a viable alternative to hexane extraction to separate oil and protein from soybeans. Different extraction strategies incorporating various modes of comminution, extraction buffers, and enzymes allow production of a range of oil and protein products, but also.

The Ultimate Guide of Soybean Oil Extraction Methods

- Usage: cocoa butter press machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 700*800*780mm

- Weight: 240 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Material: Carbon Steel or Stainless Steel

- Function: cocoa butter, Soybean , Soybean oil pressing

- Capacity: 1000kg/h

- Princple: physical squeezing

- Application: Soybean cocoa butter Soybean Oil

- Advantage 1: easy to operate

- Advantage 2: high oil quality

- Advantage 3: high oil yield

- Item: cocoa butter press machine

The standard soybean oil pressing production process includes multiple steps such as cleaning, crushing, softening, embryo rolling, steaming, pressing and filtering. Different types of oilseeds have different pressing production processes. The residual oil rate in the oilseed meal after pressing is generally about 6%.

Modern processing plants extract soyabean oil by solvent liquid transfer. Soyabeans are cleaned, cracked, dehulled and conditioned into a thin flake before they enter the extractor. Extraction is by successive, countercurrent washes of hexane solvent. The extracted flakes are then carried by a sealed conveyor to be desolventized in enclosed vessels by application of jacket and sparge steam.

- What is aqueous extract from whole soybeans?

- Within industry, aqueous extract from whole soybeans is commonly used for making consumer products containing both soy protein and soybean oil, and this has been the focus of this review. Key extraction process parameters are presented and challenges of each extraction step are given for the whole soybean extraction process.

- What is a good residual oil content for soybean meal?

- In a modern and efficient extraction plant, a residual oil content ≤ 0.5% for soybean meal is expected. The first step for an efficient solvent extraction is a good preparation process; its optimization makes it possible to shape the seeds for effective leaching and washing of the oil.

- What is soybean meal from the solvent extraction plant?

- Soybean meal from the solvent extraction plant is a mix of particle sizes; it is therefore necessary to undergo several additional process steps (meal sizing) to produce a nished fi product that meets trading rule size speci cations. fi The akes that have been shaped in the preparation plant enter the solvent extraction plant (Fig. 3).

- Which method is used to extract oil from soybean seeds?

- The conventional solvent extraction (CSE) method is commonly used to extract oil from oilseeds. Even though the extraction of oil from soybean seeds using the CSE method has been studied extensively, the application … [Show full abstract]