soybean solvent extraction production line machine in lesotho

- Usage: Soybean grits/broken Soybean machine

- Type: Soybean Oil press machinery

- Production Capacity: 1-2000TPD

- Model Number: SW-008

- Voltage: 220V/380V

- Power(W): 22kw

- Dimension(L*W*H): 2600*1300*2300mm

- Weight: 3000KG

- Certification: ISO,CE,BV

- Residual: less than 0.5%

- Technology: chemical and physical combined

- Warranty: 1year

- Projects done: 1-2000TPD in Africa,Russia,China,America,Europe

- Equipment name: Soybean grits/broken Soybean machine

- Suitable to: small and large capacity

- Land needed: designed according to the capacity

- Service: design,manufacture,installation of the equipment

- Running life: more than 20 years

- Generator: equipped

The Solvent Extraction Plant of lower capacities can be processed with flakes upto 100 to 150 tons per day. The Bigger capacities are to handle with expanded collets as the density of the flakes are very low. The density of the collets is with 35% more than the flakes. The flakes will be conditioned in horizontal flake conditioner allowed to.

Solvent Extraction. The Author: George E. Anderson, Crown Iron Works Company, P.O. Box 1364, Minneapolis, MN 55440 USA. One of the most basic needs of mankind is an abundant and reliable food supply. In the modern world, one major source of protein and vegetable oil is from oilseeds, particularly the soybean an abundant resource which is.

Solvent extraction process of soybean - Edible Oil Expeller

- Usage: chia seed cooking oil refinery equipment

- Type: chia seed cooking oil refinery equipment

Production Capacity: 100% - Voltage: 220V/380V/440V

Power(W): 5.5-22KW - Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

Certification: ISO9001 - Raw material: Soybean Seed

- Material: Stainless Steel SS304/316

- Application: Oil Production Line

Function: Chemical oil refining and physical oil refining - Application range: 10-1000tpd

- Advantage: Low consumption

Power consumption: 17.5kwh-24kwh - Steam consumption: 200-300kg per one ton crude oil

The first stage is mainly to dissolve the oil in the damaged cells by solvent. The extraction amount is large and the time is short (15~30 minutes), and the total oil content can be extracted from 85% to 90%.In the second stage, solvents are needed to penetrate into the unspoiled cells for a long time with low efficiency.

Soybean is valued for its high protein content (38-45%)) as well as its oil content (approximately 20%). Soybean oil is a vegetable oil extracted from the seeds of soybean, which has a mild nutty flavor and a better texture. It is one of the most widely consumed cooking oils, constituting about half of worldwide edible vegetable oil production.

Overview of the soybean process in the crushing industry

- Usage: Soybean Oil

- Type: edible oil solvent extraction machine, Soybean oil manufacturing machine

Production Capacity: 100% - Voltage: Local Voltage

Power(W): Capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: CE ISO - Oil residue ratio: 0.5-1%

Solvent consumption: ≤ 2Kg/T (No.6 solvent oil) - Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

Residual oil in meal: ≤ 1% (Soybean) - Crude oil moisture and volatile matter: ≤ 0.30%

- Finished meal moisture: ≤ 13% (adjustable)

Price: Competitive - Quality: Top Level

Soybean meal from the solvent extraction plant is a mix of particle sizes; it is therefore necessary to undergo several additional process steps (meal sizing) to produce a finished product that meets trading rule size specifications. The flakes that have been shaped in the preparation plant enter the solvent extraction plant . After oil.

The current technologies and green solvents used for soybean and general vegetable oil extraction are presented. Besides, main kinetic and thermodynamic approaches are reviewed, and tools for screening solvents are presented. Issues regarding cost, recovery, and reuse of green solvent are assessed.

Build a Soybean Processing Plant in the United States [Edible

- Usage: Soybean Oil

- Production Capacity: 100% Soybean oil extraction machines

- Model Number: Qie

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Certification: CE/BV/ISO9001

- Raw material: Soybean Seed

- Name: Soybean oil extraction machines

- Application: Soybean oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Advantage: high oil yield

- Flowchat: cold press/hot press/prepress/solvent extraction

The production capacity ranges from 1 ton/day to 20 ton/day. This set of soybean processing equipment can be cusomized based on your different needs and situation. The equipment prices varies according to the production output. For a setting up a 5 ton/day production line, about $7000~$8000 is needed for the equipment.

Aqueous oil extraction is an approach that could replace organic solvent extraction with water. Compared to typical solvent extraction and mechanical pressing processes, aqueous extraction has higher oil recovery (over 80%) than the mechanical pressing process, and resolve issues resulted from chemical loading and remaining in the hexane extraction. Proteases are used to assist free oil.

Equipment and turnkey plants for oilseeds crushing and oil

- Voltage: 220V/380V

- Dimension(L*W*H): Depends on capacity

- Weight: Depends on capacity

- Warranty: 1 Year, 12 Months for Soybean kernel expeller

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Raw material: Soybean

- Advantage: High Efficient and Economical for Soybean kernel expeller

- Material: Stainless Steel and Carbon Steel

- Quality: Top Level for Soybean kernel expeller

- Keep working: 12 Hours for Soybean kernel expeller

- Feature: Automatic Machine for Soybean kernel expeller

- After Warranty Service: No service, Field maintenance and repair service

- Local Service Location: Bangladesh, Nigeria

This fifth crushing line, with capacity of 3,000t/d rapeseed and 5,000t/d soybean, is the largest in terms of capacity. Core equipment of the entire production line is manufactured and supplied by Myande. The successful test production of the soybean processing line fully demonstrates Myande's strength in the oils & fats engineering.

Depending on the position in the plant, these devices can be separate or combined with screw presses in the production of soybean cake. As separate units, they are an unavoidable part of the equipment in the preparation of raw materials for the production of soybean meal and soybean flakes (see Fig. 4). 2.5 Flaking

- What is the process of soybean oil extraction plant?

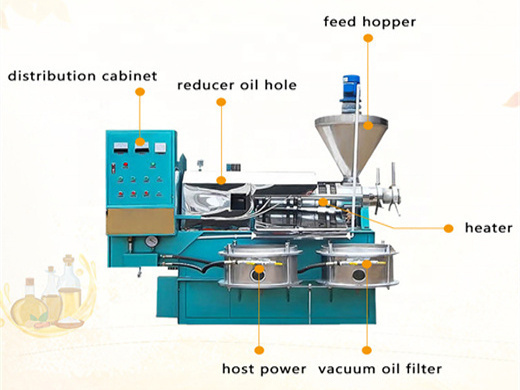

- Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

- What is a complete soybean oil mill plant?

- Complete soybean oil mill plant is usually designed with seeds pretreatment section, oil processing section, oil refining section and oil filling section. According to oil extraction methods, soybean oil production can be divided into mechanical oil pressing and solvent oil extraction.

- How to get edible refined soybean oil?

- And crude soybean oil extracted from both mechanical or solvent has impurities and should be refined through a series of oil refining process to get edible refined soybean oil. For over 20 years, Hongde Machinery has provided customers with high quality oil processing machines for various oilseeds oil extraction.

- What is tyical soybean oil refining process?

- Tyical soybean oil refining process is degumming, deacidification, decoloration, deodorization. After above processes, edible refined soybean oil is produced and can be sale in the market. Generally, edible oil can be packed in PET barrels, glass bottles, tin barrels and so on.

- Voltage: Local Voltage

- Voltage: 220V/380V/440V