soybean seed screw oil extruder in togo

- Usage: Soybean Oil, Cooking Oil

- Production Capacity: 10-2000T/D

- Voltage: 380V/220V

- Dimension(L*W*H): Up to specification

- Weight: Up to specification

- Core Components: Motor, Pressure vessel

- color: green or red

- material: carbon steel or stainless steel

- package: nude or according to customers' require

- delivery date: within 35 days after customer confirm the order

- After Warranty Service: Video technical support

- Local Service Location: Bangladesh, Uzbekistan

- Certification: ISO, BV

the extruding-expelling method. For canola having 35?40% oil content, the residual. oil content in meal was 8?11%. In the case of sunflower seed with 35?45% oil con-. tent, the residual oil.

Shaped Products. Offering quality output for a low capital investment, our medium-shear, single-screw extruder is a cost-effective solution for processing a variety shaped products, as small as 1.5 mm. Patented Insta-Pro technology improves chemical-free feed & food oilseed processing with exemplary equipment.

Technology of Soybean Extruding and Pressing

- Usage: Soybean Oil

- Type: Soybean oil press machine prices

- Production Capacity: 98%-100% Soybean oil press machine prices

- Model Number: DT Soybean oil press machine prices

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Dimension(L*W*H): 1400*600*600mm

- Weight: 1200kg

- Certification: CE ISO

- Name: Soybean oil press machine prices

- Color: Silver, red, yellow, green, blue

- Oil yield: 98%

- oil residual: 1-5%

- labor force: 3 persons

- land needed: different sizes

- Material: Stainless Steel 304

- Productivity: 1-2000TPD

- motor: Siemens

- maintenance: engineer service

TXP160 type soybean extruder is the main technological equipment for soybean extruding and also can be used to manufacture different expanded feeds in oil mills, rice mills, soybean protein factories and feed mills. This extruding machine can transfer mechanical energy to thermal energy by extrusion, friction and shearing function of non.

The Dox Extruder simplifies upstream processing for seed oil extraction by combining multiple processes into a single step. This multi-functional machine unlocks several critical benefits for oilseed processors: 1. Reduced energy consumption. Because the Extruder generates heat from mechanical friction rather than external heating elements, it.

High-Shear Extruder Adds Extreme Flexibility For Soybean Oil

- Usage: Soybean Oil

- Type: Cold & Hot Pressing Machine, Soybean oil press machine

- Production Capacity: 1TPD-500TPD

- Model Number: 6YY-260

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Certification: ISO9001-2008, CE, BV

- Color: According to customer demand

- Production Material: Carbon steel, stainless steel

- Raw material: Soybean Seed

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Extreme flexibility. Unlike wet extruders or other dry extruders on the market, the high-shear Dox design allows for more flexibility in a processing plant. The Dox can accommodate variations in seed type and oil content, offering versatility to the facility, and the design also can extend the time between maintenance and improve safety.

EP2 Two-stage pressing with extrusion. In cold pressing, the seeds are not heated up prior to pressing. The temperature of expelled oil does not 50 °C. This technology thus yields the highest-quality cold-pressed oil. However, the oil yield is overall lower, due to a significant amount of fat retained in the press cake (10 - 12 %).

Oilseed Equipment - Anderson International Corp

- Usage: crude Soybean Oil refinery production line

- Type: Cold & Hot Pressing Machine

Production Capacity: 45 sets per year - Voltage: 380V/440V

Power(W): 30KW - Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

Certification: CE/ISO9001/BV - usage: crude Soybean Oil refinery production line

oil clolor: yellow - advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

decolor function: remove the bad color - deodor function: remove the bad smell

- Name: crude Soybean Oil refinery production line

Oilseed Extraction Equipment Anderson International, as the inventor of the original continuous mechanical screw press, has been a global leader in the vegetable/oilseed extraction industry for 130 years. We’ve designed, manufactured, and commissioned over 12,000 pieces of processing equipment for over 1,000 plant installations in over 100 countries, processing in excess of 100 different.

The optimized oil extraction efficiency (OEE) by extruding-expelling of soybeans seeds (Glycine max) is slightly higher than 70 % (Bargale et al., 1999; Nelson et al., 1987). However, in a survey.

Multi Oil Seed Processing Plant with Extruder Installed in

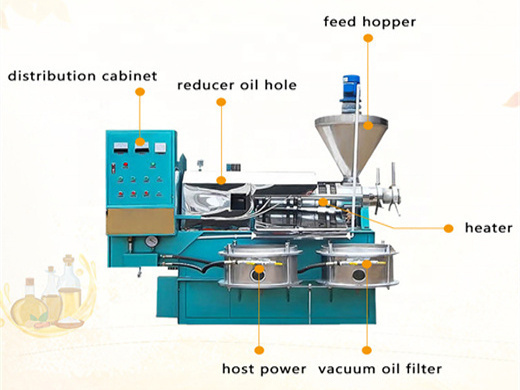

- Usage: edible oil

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1950*560*760

- Weight: 500 KG

- Warranty: 1 Year, 12 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- Advantage: high oil yield

- Machine Material: Carbon steel; Stainless steel

- Used for: Edible Oil Making

- Feature: High Efficiency Low Cost

- Quality: Top Level

A set of Multi Seed oil Processing plant was installed in Ethiopia recently having an input capacity of 60 tons per day. This soya oil plant includes a series of oilseeds processing equipment, such as an Elevator, Screw Conveyor, Seed Cleaner, De-stoner, Seed Cracker, Soybean Extruder and Screw Press to extract Oil & High-Protein Soymeal.

Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively.

- Why is organic soybean production growing in Togo?

- Togo’s organic soybean production continues to expand as the small West African nation deepens its trading ties with the EU and other keen buyers. The sector has benefitted from grassroots organization as well as policy support from the top. Organic soybean stakeholders met about 90 miles outside the capital Lomo in Atakpame on September 6.

- What are the processing technologies for soybean oil?

- There are two main processing technologies on the market to produce soybean oil, called the pressing method and the extraction method. Different processing technologies require different processing equipment for soybean oil.

- How a soybean extruder works?

- The raw material is processed in the extruder for no more than 30 seconds. Therefore, both proteins and fats in soybeans retain their nutritional qualities.Raw material is fed into the working body of the extruder by a screw feeder (with frequency control of speed)

- Where to buy soybean oil extraction machine?

- Shop for the most effective. soybean oil extraction machine at Alibaba.com for all types of commercial oil extraction, pressing, and expelling purposes. These sturdy and competent. soybean oil extraction machine are ideal for all types of oil processing mills and plants to double the production and deliver consistent performance for a long time.

- Voltage: 380V/440V