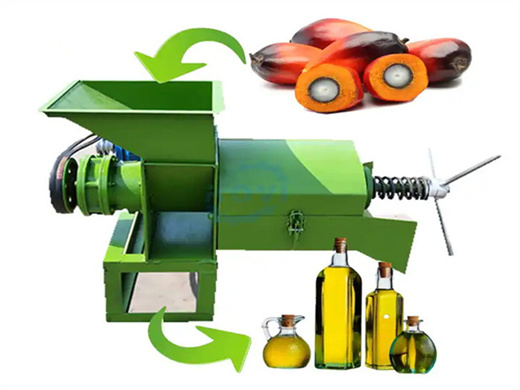

rate palm small oil extraction machine in uganda

- Usage: Palm OIL, All kinds of oil s

- Voltage: 220

- Dimension(L*W*H): 2600*1000*1450

- Weight: 2500 KG

- Core Components: Motor

- Oil type: Palm Oil

- Product name: Soyabean Palm Oil Making Machine Cooking Oil Making Machine

- Raw material: Palm

- Function: Press Oil s

- Application: Oil Production Line

- Application range: Kinds s

- Extraction of Oils: 90% Oil Yield

- Processing Types: Screw Pressing

- Character: Easy Movable

- Material: 304 Stainless Steel

- Capacity: 1000KG

66 JOURNAL OF OIL PALM RESEARCH 33 (1) (MARCH 2021) There is a need to increase the supply of palm oil for meeting the food security needs of the world (Mahmud et al., 2010) since the demand for palm oil is not only growing in the food sector but

DOING small scale palm oil processing plant is designed for 1-2tph palm oil mill plant. The machines used in palm oil processing process is palm fruit sterilizer, palm fruit thresher, palm fruit digester,double screw palm oil presser and so on.

4. TRADITIONAL TECHNIQUES AND INNOVATIONS IN SMALL-SCALE PALM OIL PROCESSING - Food and Agriculture Organization

- Type: Palm processing machine

- Use: Palm processing machine

- Model Number: Palm processing machine, 1-200T/D

- Product type: Palm processing machine

- Residual oil in cake: 1%

- Key word: Palm processing machine

- Solvent: n-hexane

- Voltage: 380V or 440 V

- Application: Palm processing machine

- Extractor type: rotocel extractor

- Usage: Palm processing machine

- Dimension(L*W*H): according the capacity

4.1 Mechanical extraction. Pounding (digestion) and oil extraction are the most tedious and essential operations in traditional palm fruit processing; therefore early efforts concentrated on these tasks. In small-scale processing, digestion, the breaking up of the oil-bearing cells of the palm fruit’s mesocarp, is the most labour intensive.

Palm oil is the world’s most-produced vegetable oil that is serving as an important source of food and energy for many developing and underdeveloped countries. The global demand for palm oil will continue to rise, owing to the growing population and economy. Presently, tremendous efforts have been devoted to improving the sustainability of palm oil production. One strategy is to improve the.

Preliminary Design on Screw Press Model of Palm Oil Extraction Machine - ResearchGate

- Usage: Cooking oil production line

- Type: Cooking oil production line

- Production Capacity: 10TPD

- Voltage: 380V

- Weight: 10000 KG

- Core Components: Motor, Gear

- Oil type: Palm Oil

- Name: Cooking oil production line

- Raw material: Palm , Palm, etc

- Feature: High Oil Yield Efficiency

- Quality: Stable

- Oil rate: Press Cpress Cake Residual: 6%

- Method to press: Screw Squeezed Press

- Suitable for: Oil factory

- MOQ: 1SET

- Delivery: 30 Working Days

- Package: Standard Wooden Case

The digester screw press had the highest extraction rate and oil yield of 13.5 and 25.5% respectively while the digester with separate hand-operated screw press had the lowest extraction rate and.

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Small palm oil press machine - vegetable oil extraction machine

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 30kg/h Palm Oil Making Machine

- Voltage: 220V/380V

- Dimension(L*W*H): 800*650*1100mm

- Weight: 530kg

- Core Components: Motor

- Oil type: Palm Oil

- Product name: Motor Palm Fish Oil Making Machine

- Function: Palm Oil Processing Machine

- Advantage: Simple Operation

- Application: Palm Oil Processing Machine

- Capacity: 30kg/h

- Useage: Palm Oil Making Machine

- Pressure: 55Mpa

- After Warranty Service: Video technical support, Online support

- Certification: CE ISO

palm oil press machine. 1, 5, 10, 15 t/h. 7.5-30 kw. 20-12.5 r/min. 180-6500 kg. 3-10 m?. Our screws are made of 2Cr13 material, wear-resistant alloy steel and integrated casting process. Normal maintenance can be used for half a year or a year. It can reduce the manpower, material resources and time cost.

Application: High Efficiency Crude Oil Pressing & Extracting From Palm Kernel With Low Oil Residual Solvent extraction plant is recommended for large palm kernel oil mill with high capacity. However, For the purposes of small-scale operations it is sufficient to mention the solvent extraction process is an alternative for high capacity mills.

HOME - palm oil line

- Usage: Palm Oil, Palm EDIBLE OIL

- Production Capacity: 15 ton/day

- Voltage: 380V/440V

- Dimension(L*W*H): Depend

- Weight: KG

- Core Components: Gearbox

- Oil type: Palm Oil

- complete Warranty Service: Video technical support

- After Warranty Service: Spare parts

- On site Warranty Service: Field maintenance and repair service

- Raw material: Oil s

- Function: Making Edible Oil

- Product name: Oli Press Machine

- Application: Edible Oil Production

- Keyword: oil Expeller

- Used for: Edible Oil Making

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

PALM OIL EXTRACTION MACHINE designed by Wintone has the follow features and advantages: 1. Adopt stainless steel fixed grid plate and increase the horizontal grid plates, which can prevent the strong miscella from flowing back to the blanking case, so as to ensure good extraction effect; 2. The palm oil extraction machine is driven by rack.

- What is palm oil extraction machine?

- Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill.

- Can a motorised palm oil extractor be used to extract Palm oil?

- The PV was not detected for both methods. A motorised palm oil extractor produced oil of higher uality and had higher performance efficiencies as compared to the manual vertical press. The novelty of this work was in producing an efficient euipment that is affordable to a smallholder farmer which extracts palm oil of high quality.

- What are the different types of palm oil making machines?

- There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

- How many hectares will Uganda need under oil palm?

- OPUL’s Damanik said Uganda will need 100,000ha under oil palm if it is to fully substitute its palm oil imports at the current consumption rates. He adds that such production can only be achieved through oil palm because of its higher yield of oil compared with other crops, which would require a lot more land.