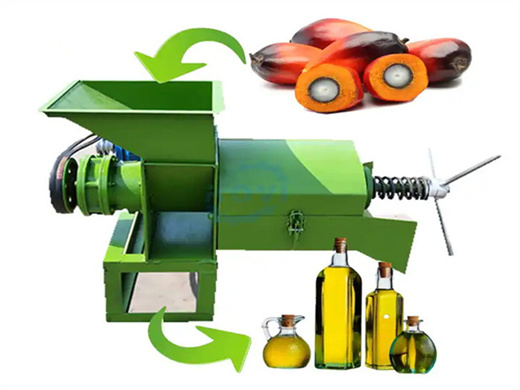

palm kernal oil extraction machine in zimbabwe

- Usage: Other

- Production Capacity: 98%-100%

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2280*700*780mm

- Weight: 750kg

- Marketing Type: Other

- Warranty of core components: 1 Year

- Core Components: Motor

- Name: screw oil pressing machine

- Raw material: Palm, Palm Kernel

- Material: Stainless Steel 304

- Function: Making Palm Oil

- Advantage: Energy Saving

- Product name: Screw Press Oil Expeller

- Application: Palm oil pressing

- Capacity: 300-400kg/h

- Item: Palm Oil Press

- Keyword: Screw Oil Expeller

- After Warranty Service: Online support

- Local Service Location: None

- After-sales Service Provided: Video technical support, Online support

- Certification: CE ISO

The choke mechanism Machine Capacity: The theoretical capacity of the expeller was determined as 280.6kg/hr using a modified form of the equation given by (Adetola et al (2014) as: Q c = 60 π 4.

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

Palm Oil Equipment,Palm Kernel Screw Press,Oil Expeller

- Usage: refining crude oil to Palm oil

- Type: oil refinery plant

- Production Capacity: depend on clients' request

- Voltage: 380V/50HZ

- Dimension(L*W*H): depend on the capacity

- Weight: 140-350kg

- After Warranty Service: Video technical support, Online support

- Local Service Location: None

- After-sales Service Provided: Field installation, commissioning and training, Video technical support, Online support, Engineers available to service machinery overseas

- Certification: ISO CE SGS

- Raw material: Palm, Palm Kernel

- Application: Palm, vegetable, Palm oil

- Capacity: 500-2500kg/day

- Advantage 1: High Oil Yield, High oil quality

- Advantage2: low investment fast recovery

- Standard: national 1st grade Palm oil

- Item: oil refinery plant

- Name: Oil Refinery Equipment

- Function: Oil Refining

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Properties, machines and processes for industrial extraction and refining of palm kernel oil: a brief guide - ResearchGate

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Palm Oil Processing Equipment

- Production Capacity: 10t/d

- Voltage: 380V/customized

- Dimension(L*W*H): 2900*1850*3240mm

- Weight: 5000 KG

- Core Components: Motor

- Oil type: Palm Oil

- production name: Palm oil mill for sale

- keyword1: Palm oil mills

- keyword2: fully automatic Palm oil mill

- Raw material: Palm, Palm, Palm , Palm

- Application: Oil Production Line

- Feature: High Oil Yield Efficiency,large capacity

- Certification: CE/ISO

- Processing Types: physical press

- Quality: High-Quality

- Advantage 1: factory price

Palm kernel oil (PKO) extraction and refining techniques involves operations such as sorting of kernels, handling, mechanical pressing, filtration of crude oil, thermal, chemical and.

The amount of crude palm oil extraction at full capacity of the machine was found 8 kg hr-1 , which is higher than any manually operated extracting machine available in the market.

Palm and Palm Kernel Oil Production and Processing in Malaysia and Indonesia

- Usage: oil press machine

- Production Capacity: 98%-100%

- Voltage: 220V/50HZ/Single phase

- Dimension(L*W*H): 450*180*310mm

- Weight: 11 KG

- Warranty of core components: 1 Year

- Core Components: Motor

- Raw material: Palm, Palm Kernel

- Name: Home Use Oil Press Machine

- Product name: Press Oil Expeller

- Function: Oil Pressing Palm etc.

- Advantage: Energy Saving, High Oil Yield etc.

- Material: Carbon steel or stainless steel

- Output: 2-6kg/h

- Application: Food Industry

- Color: Silver

- Item: Palm Oil Press

- After Warranty Service: Video technical support, Online support

- Local Service Location: None

- After-sales Service Provided: Video technical support, Online support

- Certification: CE, ISO

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding.

Palm Kernel Oil Expeller is a special purpose oil extraction machine for producing the ultra clean Palm Kernel Oil. The palm nuts and palm kernels are crushed to give the Palm Kernel Oil and Palm Kernel Cake. So get in touch with Tinytech Udyog for more information on our robust palm kernel expellers.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at Factory Price

- Usage: chemical Oil, Palm

- Type: Palm & Palm Kernel Oil Pressing Machine

- Automatic Grade: Automatic

- Voltage: 220V

- Dimension(L*W*H): 600 * 306*775MM

- Weight: 14 KG

- Marketing Type: Ordinary Product

- Warranty of core components: 1 Year

- Core Components: Pump, PLC

- Oil type: Palm Oil, Palm Kernel Oil

- Product name: Oli Press Machine

- Raw material: Palm

- Function: Making Edible Oil

- Application: Palm Oil Production

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

Learn more about Kumar's range of Palm Kernel (PK) Series Oil Expeller Machines. Sales +918928445250 Purchase +918411986196 [email protected] CSR News Blog Careers Events.

- What is palm kernel oil extraction process?

- PALM KERNEL OIL EXTRACTION Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extraction of palm kernel oil.

- What is a palm kernel oil expeller machine?

- A high torque and low rotational speed palm kernel oil expeller machine was developed by introducing an adjustable choke mechanism that permits adjustment of the back pressure to regulate the thickness and dryness of the pressed cake passing through the clearance between the barrel and the screw shaft.

- What are the different types of palm kernel machines?

- The nutcracker, kernel/shell separator and palm kernel expeller are produced to handle palm kernel. The expeller has machined flights on a single shaft with threaded backpressure cone. Generally machines are produced having a 1 tonne/hr capacity for palm oil while the palm kernel machines have rated throughputs of 150-250 kg/hr.

- How is palm oil extracted?

- Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil.