palm oil mill machine essential oil extraction equipment in togo

- Model NO.: 50 tpd

- Machine Usage: Biodiesel Oil Making

- Manufacture Period: According to Your Processing Material and Capacity

- Installation Period: According to Machine′s Capacity

- Running Machine Visiting: Avialable

- Installation Overseas: Avialable

- Easy Broken Spare Parts: Easy to Buy

- Staff Training: Charge of Free

- Warranty Period: 12 Months

- Transport Package: Wodden Package

- Specification: CE & ISO-9000

- Production Capacity: 3000 Sets/Year

A faster determination method for oil content in the samples of pressed fibre, sludge, steriliser condensate and empty fruit bunches in palm oil mill processing points is needed to monitor and.

The characteristics of Palm Oil Mill Effluent (POME) is a crucial factor affecting the yield and quality of biogas produced from anaerobic digestion. Hence, it is essential to understand how the operational processes and equipment in palm oil mills can affect POME characteristics and subsequently, biogas production efficiency.

Improving Sustainability of Palm Oil Production by Increasing

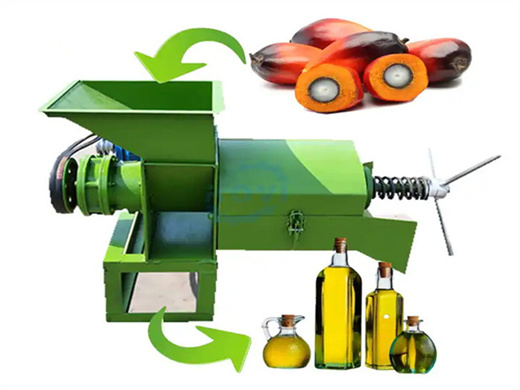

- Model NO.: 6YL-95A

- Customized: Non-Customized

- Capacity: 150-200kg/H

- Power: 7.5kw

- Weight: 940kg

- Certificate: Ce

- Output: Edible Oil

- Output Color: Light Yellow and Pure

- Machine Color: as Requirement

- Texture: Carbon Steel and Stainless Steel

- Operator No.: One Person

- Transport Package: Ply Wooden Case

- Specification: 2050*1050*1850mm

- Production Capacity: 50 Sets/Month

A palm oil mill typically adopts a solvent-free process that uses steam and water for oil extraction. Interestingly, the process to extract the oil from the palm fruitlets has remained relatively unchanged for the past 50 years. Figure 1 shows the block flow diagram of a typical palm oil mill for the production of crude palm oil. The major unit.

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack.

Palm oil processing and production process | Alfa Laval

- Usage: Palm Oil/Basil oil/Palm oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 10kg/h-1000kg/h

- Voltage: 110V/220V240V/380V/450V/customization

- Dimension(L*W*H): 700*800*800mm

- Weight: 250 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel

- Oil type: Palm oil, Rap seed oil, Palm Oil, Basil oil, Palm OIL, Pinenut oil, Palm oil

Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil processing solutions for the entire supply chain milling, POME management, refining and more. Our complete range helps you increase yield while meeting increasingly strict environmental.

The amount of crude palm oil extraction at full capacity of the machine was found 8 kg hr-1 , which is higher than any manually operated extracting machine available in the market. The crude oil.

Essential Oil Extraction Process | IntechOpen

- Usage: plant oil refining equipment

- Type: plant oil refining equipment

- Production Capacity: 100%plant oil refining equipment

- Model Number: plant oil refining equipment

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Machine Name: Plant oil refining equipment

- Raw material: Palm, Palm Kernel

- Color: according to customer requirement

- Application: Oil Production

- Production period: 45-90 days

- Supplier Type: manufacturer

- Technology support: lifetime

- Function: High production

- Advantage: Energy Saving

Essential oils can be extracted using various methods. Process choice significantly impacts yield and quality, leading to the development of processes aiming for maximum essential oil (EO) yields in a chemical state close to their native structure. In this chapter, various extraction techniques, including conventional ones and their intensification, are discussed along with their respective.

The oil recovery from PPF can contribute to an OER increase of approximately 0.46% to 0.6%. Out of approximately 450 palm oil mills in Malaysia, only about 10 to 15 mills are installed with the PPF solvent extraction plants. The total production capacity is ap-proximately 1500 to 2000 tons of crude fibre oil monthly.

ADLERMECH - Essential Oil Distillation, Extraction

- Usage: Palm Oil

- Production Capacity: 3t/h palm oil processing machine

- Voltage: 380v/50hz

- Dimension(L*W*H): 2460*1060*600mm

- Weight: 700 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- After-sales Service Provided: Engineers available to service machinery overseas

- Name: 3t/h Palm fruit oil expeller

- Raw material: Palm, Palm Kernel

- Function: processing fresh palm fruit buch

- Application: Palm Oil Production Line

- Advantage: high oil output and low energy consumption

- market: Nigeria,Ghana,Uganda,Cameroon,Congo,Benin,Zimbabwe

- Item: Palm Oil Press

- main machines: sterilizer,thresher,digester,oil press,clarification,filter

Essential Oils of Nature. At Adlermech, we are dedicated to providing high-quality essential oil distillation and extraction equipment to clients around the globe. Our clients in the United States, Indonesia, Saudi Arabia, Russia, and Africa have consistently expressed their satisfaction with our products.

4.1 Mechanical extraction. Pounding (digestion) and oil extraction are the most tedious and essential operations in traditional palm fruit processing; therefore early efforts concentrated on these tasks. In small-scale processing, digestion, the breaking up of the oil-bearing cells of the palm fruit’s mesocarp, is the most labour intensive.