palm oil extraction cold press national machine in indonesia

- Model Number: LBQ8614-20200821-03

- Raw Material: s

- Supply Type: OEM/ODM

- Available Quantity: 9999

- Type: Pure Essential Oil

- Ingredient: Organic Clod Pressed Palm Oil

- Feature: Eyelash/Brows/Hair growth, Hair Growth

- Advantage: 100%Safe

- Product name: Hair Growth Oil

- Certificates: MSDS

- Function: Hair Growth

- Service: OEM ODM Privare Label

- Usage: Oil Apply

- Volume (ML): 10ml

- Hair Type: All Type

- Certification: GMP, MSDS

In the cold-pressing process, oil is extracted by only exerting pressure on the seeds at a low temperature exclusive of chemicals or extreme heat (Cakaloglu et al. 2018). The samples of each meal.

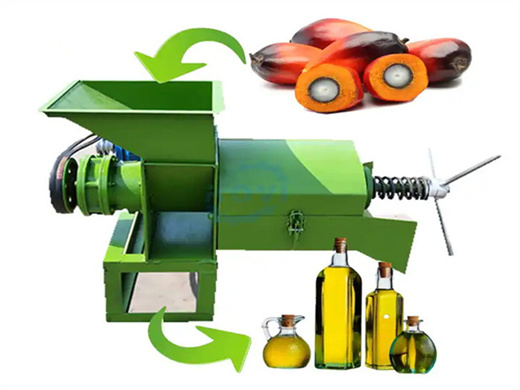

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

Palm and Palm Kernel Oil Production and Processing in

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 100TPD

- Voltage: 380V/440V or required, 380V/440V or required

- Dimension(L*W*H): 2000*1300*1850MM, 2000*1300*1850MM

- Weight: 1250 KG

- Core Components: Pressure vessel

- Oil type: Palm Oil

- Application: Oil Production Line

- Item: Industrial Oil Extractor

- Function: Making Edible Oil

- After-sales Service: Engineers available to service

- Advantage: High Oil Yield

- Raw material: Palm, Palm ,Palm

- Material: Stainess Steel/Carbon Steel

- After-sales Service Provided: Field installation, commissioning and training

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding.

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Palm Oil Extraction Process, Methods, Steps | Agri Farming

- Usage: multifuntional

- Production Capacity: 150-300kg/h

- Model Number: H6YL-100

- Voltage: 220V/380V

- Power: 7.5kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Certification: ISO CE SGS

- Palm oil mill plant in bd: Palm oil mill plant in bd

- Material: 316 Stainless Steel

- Screw Dia: 100mm

- Cake oil rate: 6%

- Level: 4

- Multi-purpose: yes

- Oil filter: 2

- Color: Clients' requirements

- Raw material: Palm

- Movable: Yes

A good benchmark is a palm oil processing machine with an ability of 50 sheets priced at around $2,000.00 $3,000.00. More complex machines that include oil press machine with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm normally range from $5,500 $7,000.00.

However, the process technologies and the quality of palm oil produced have remained stagnant for the past decades. This paper reviews the latest development in the process technologies that can be applied in the palm oil milling process to improve the sustainability and efficiency of palm oil production, as well as the quality of the oil produced.

Development of Palm Oil Extraction System - ResearchGate

- Usage: Palm

- Type: oil refining machine

- Production Capacity: 100

- Voltage: 220V/380V

- Weight: 1000 KG

- Marketing Type: Hot Product

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Name: crude oil refinery machine

- Advantage 2: Multifunctional

- Advantage 1: Energy Saving & Simple Operation

- Function: Oil Refining

- Raw material: Palm, Palm Kernel

- Feature: Low Labor

- After-sales Service Provided: Provide Longlife Technical Support

- Application: Palm Oil Processing Line

- Material: Carbon steel/stainless steel

A vertical oil palm digester design was made to feed the screw press by gravity. Detailed design of the screw press hereby presented. Much emphasis was however made in the use of available local.

A remote sensing assessment found that oil palm plantations covered at least 19.5 Mha globally in 2019 (Fig. 2), of which an estimated 67.2% were industrial-scale plantings and the remainder were.

A Systematic Approach for the Synthesis and Optimisation of

- Capacity: 30-40kg/h

- Weight: 40 KG

- Marketing Type: Hot Product

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Main market: Africa, America, Europe

- MOQ: 1

- Delivery: 15-25 working days

- Color: Customerized

The present study was conducted to produce carotenoid-rich virgin palm oil (VPO) using cold-press extraction. Herein, the influence of sterilization of oil palm fresh fruits in the production of.

Since 1950s, manufacturers also started using refining process for groundnut, sesame, Palm, etc. Refined oil extraction has higher oil yield. For example, in cold pressed method we need 2.5kg of groundnuts to make 1 litre of groundnut oil. The refined process will extract 1 litre of oil from 2.2 kg of groundnuts.

- What is palm oil extraction machine?

- Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill.

- How do palm kernel machines work?

- The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil seeds. The oil that is expelled then seeps through the small openings into a container. These openings are very small which prevents any kind of solid material or residue from the seeds to mix with the extracted oil.

- What is the extraction rate of palm oil?

- The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?23% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B. Fig. 8.3.

- What are the business models for palm oil production in Indonesia?

- The three main business models for palm oil production in Indonesia are private large scale plantations, nucleus estate smallholders, and independent smallholders. The breakdown of palm oil area and production by type of palm oil plantation is shown in Table 1.