direct sale peanut oil extraction plant in lusaka

- Usage: Mustard Oil, Peanut Oil

- Type: Oil Extraction Machine

- Production Capacity: 10 TONS /DAY

- Voltage: 30 hp

- Dimension(L*W*H): 2175MM*1200MM*2200MM

- Weight: 1500 KG

- Core Components: Motor, Bearing, Gearbox

- Oil type: Peanut Oil

- Extraction of Oilseeds: Peanut ,Cotton,Peanut,Peanut ,Peanut Kernel ,Peanut

- MOTOR: 30 HP

- CAPACITY: 10 Tons/Day

- After Warranty Service: Spare parts

- Certification: ISO 9001-2008

We can provide you the turn key project of the whole peanut oil extraction plant from 20 to 2000TPD . As manufacturer of peanut oil extraction plant, we can offer whole line or parts of peanut oil extraction plant with general capacity from 10TPD to 6000TPD. For special capacity, our engineers can also help you design and install workshop.

Fragrant Peanut Oil Production Line. The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical.

Peanut Oil Processing Technology

- Usage: cold press Peanut oil press

- Type: Oil Pressing Machine

Production Capacity: 100% - Voltage: 380V

Power(W): 2KW - Dimension(L*W*H): 1650*1200*1720

- Weight: 630

Certification: SGS - Product name: cold press oil expeller machines

Gear ratio of gear case: 14/42x19/57=1 - Main engine power: Y160L-6-5.5KW

- Vacuum pump power: Y90S-4-0.55KW

Residual oil rate: 6~7% - Raw material: Peanut

- Function: Cold/Hot Press

Advantage: Energy Saving - Feature: High Output

- Application: cold press oil expeller machines

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Watch Video. We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Processing and Food Uses of Peanut Oil and Protein

- Usage: chia seed oil manufacturer

- Type: chia seed oil manufacturer

Production Capacity: 100%chia seed oil manufacturer - Voltage: 220V/380V/440V

Power(W): 5.5-22KW - Dimension(L*W*H): 48m*12M*15M(50tons)

- Weight: 50tons

Certification: ISO9001 - Raw material: Peanut

- Application: Food Industry

- Material: Carbon Steel Q235

Application range: 100KG-100TPD - Advantage: Simple Operation

- Use for: All kinds of oil seeds

Character: Oil Processing Line - Item: Edible Oil Press

A ton of shelled peanuts increased oil yield to 100?115 gallons and 1100?1200 pounds of cake at 40?50% protein. Data ( Dean and Sanders, 2009) on the oil content of 108 peanut cultivars grown in Tifton, Georgia, indicate a maximum of 47.8% oil and a mean of 44.2% oil.

Raw Material For Manufacturing Peanut Oil. The most important raw material for peanut oil is groundnut seed which is procured from the local market, and this seed gives 44.5 to 50% oil, 50-55% meal. The remaining raw materials for Groundnut oil production are caustic soda, bleaching earth, and packaging consumables.

Bioactive Phytochemicals from Peanut Oil Processing By-products

- Usage: Peanut Oil, Kitchen

- Voltage: 220v

- Dimension(L*W*H): 53*55*35cm

- Weight: 23kg

- Name: oil pressing machine

- Application: Food Industry

- Function: Automatic

- Material: Different type has different material

- Capacity: Customized

- Color: Any

- Advantage: Good quality and service

- Raw material: Peanut......

- Feature: Easy Operation

- Certification: ce

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68?72% of the peanut, while the balance 28?32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

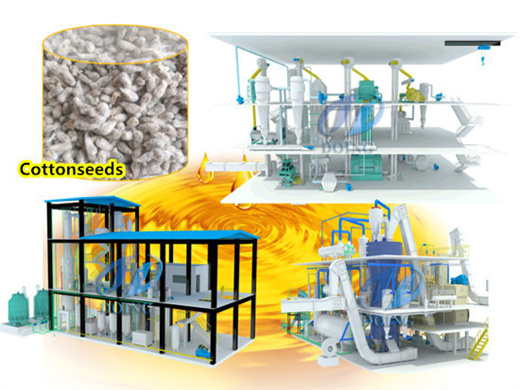

The first two steps—cleaning and shelling—happen before the peanuts arrive at the oil mill. Inside the peanut oil extraction plant, roller mills crack the peanut kernels into smaller pieces to increase the surface area for conditioning and pressing. This also removes the peanut skins, which can be blown off with an air separator.

oil expeller, refinery, solvent extraction plant manufacturers in Lusaka, Zambia

- Usage: Peanut Oil

- Type: edible oil mill machinery

- Production Capacity: 100~~150T/D

- Model Number: GQ-0228

- Voltage: adjustable

- Power(W): According to the capacity

- Dimension(L*W*H): 430*230*350

- Weight: 1050 KG

- Certification: ISO9001

- Application: various seeds, like Peanut etc.

- Grade: high

- Item: machine for Peanut oil extraction

- Business type: manufacture

- Market: all the countries

- Main equipment: extractor, DTDC, evaporator, condenser

- Material: Stainless steel and carbon steel

- Extracting method: Solvent extraction method

manufacturers & exporters of soybean, cottonseed, sunflower oil expellers, oil milling machinery, edible oil refinery, solvent extraction plant in Lusaka, Zambia +91 9780771062, +91 92163-00009 [email protected]

peanut oil extraction. Peanut oil is an organic edible vegetable oil, obtained by pressing peanut kernels, which contain about 50% oil. Peanut oil has high energy and very good lipid profile. Its smoke point is very high, so it’s widely used in deep frying. What’s more, peanut oil is one of the healthiest cooking oils as it is low in.

- What is peanut oil production line?

- The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is the production process of fragrant peanut oil?

- Production Processes The raw material which is used to produce fragrant peanut oil is fresh, full-grained, undamaged, mildew-free, free of insects and has not undergone an aging period. Raw materials would be cleaned by removing immature, damaged, and moldy grains during the cleaning process.

- Voltage: 220V/380V/440V

- Voltage: 380V