100t/d peanut oil solvent extraction plant in uganda

- Type: Pressing Machines

- Application: Beans

- Voltage: 380V

- Appearance: Vertical

- Press Materials: Peanut

- Press Series: Fourth

- Customized: Customized

- Transport Package: Wooden Box

- Specification: 700*500*800mm

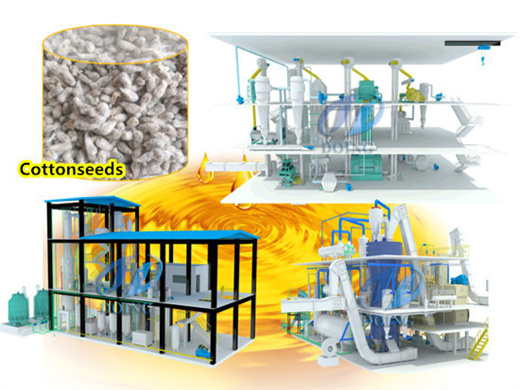

2) 80T/D Rapeseed Primary Pressing Line in Huangzhong County 3) 200T/D Cottonseed Pretreatment,100T/D Extraction,50T/D Oil refining Complete Line in Hunan Province 4) 500T/D Rapeseed Oil Processing Line in Hunan Province 5) 300T/D Rapeseed Oil,180T/D Soyabean,200T/D Extraction Line in Xiaogan City 6) 200T/D Aroma Peanut Oil Processing Line in.

Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into.

Groundnut Oil Making Process (Peanut), Business Plan

- Usage: Peanut screw oil press

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/50HZ triphase

- Dimension(L*W*H): 1055*805*345mm

- Weight: 27.1 KG

- Warranty: 1 Year, 1year

- Core Components: Motor, Engine

- Oil type: Peanut Oil

- Name: oil pressers sun flower

- Advantage: High Oilput

- Character: Easy Movable

- Function: Oil Pressing

- Color: Customer Required

- Quality: High Level

- Operation: Easily

- Keyword: Peanut Oil Solvent Extraction Equipment

- Model: TS-BXG-128

The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Solvent oil extraction is the most efficient extraction process for extracting crude edible oil from oil seeds and oil cake using solvents such as Hexane. We provide turnkey solutions for batch and continuous type solvent extraction systems with a throughput starting at 50 tons per day. The benefits of the solvent oil extraction process include: High oil yield with less than 1% residue in cake.

Peanut Oil Processing Technology

- Usage: Peanut kernel cracker

- Type: Peanut kernel cracker

- Production Capacity: 100%

- Model Number: Peanut kernel cracker

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Peanut

- Product: Peanut kernel cracker

- Solvent name: n-hexane

- Capacity: 1-3000TPD Peanut kernel cracker

- Oil content in Peanut: from 18-22%

- Oil residues: less than 1%

- Function: Peanut kernel cracker

- Manufacturing experience: 40 years

- Warranty: 1 year

- Material of equipment: stainless steel and carbon steel

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60?70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the.

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n -hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a solvent has lead to several.

Base Oil Solvent Extraction Refining Plant - VMETS

- Usage: Peanut Oil

- Production Capacity: >=3.5TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1790*1520*1915

- Weight: 1023KG

- Product name: YZLXQ10(95) Peanut Oil Making Machine Fully Automatic Mustard Oil Mill

- Color: can be customized

- Capacity: 145kgs/h

- Raw material: Oil Seeds

- oil content of dry cakes: <=7.8%

- spiral axes rotate speed(r/min): 32-40

- Advantage: Simple Operation/high efficiency

- Application: Screw Oil Expeller

- Material: Carbon Steel Q235

- Company character: manufacturer with export right

- After Warranty Service: Video technical support, Spare parts

- Certification: ISO9001: 2008;SGS;TUV

Solvent Extraction is the term for the removal of most of the ring structures and aromatics (weak, undesirable components) of oil distillates by liquid extraction. Common and suitable solvents are phenol, furfural and sulphur dioxide. Furfural is used extensively as the extractant for the refining of paraffinic oils.

Solvent Extraction. The Author: George E. Anderson, Crown Iron Works Company, P.O. Box 1364, Minneapolis, MN 55440 USA. One of the most basic needs of mankind is an abundant and reliable food supply. In the modern world, one major source of protein and vegetable oil is from oilseeds, particularly the soybean an abundant resource which is.

Peanuts Solvent Extraction Plant - Oil Mill Machinery

- Usage: oil seeds

- Type: Cooking Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 380v

- Dimension(L*W*H): 1200*400*900mm

- Weight: 260 KG

- Warranty of core components: 2Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Oil type: Peanut Oil

- Name: oil press machine

- Function: Peanut oil press machine

- Raw material: Peanut/hemp/avocado/mustar

- Machine Material: Carbon Steel/ stainless steel

- Advantage: Energy Saving & Simple Operation

- Package: Steel cage export

- Delivery time: 50-700 Days

- Machine color: white

- Quality: High Level

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%. Peanuts / Groundnuts are.

Solvent Extraction Plant Manufacturers. As a leading manufacturer and exporter of Solvent Extraction Plants, we take pride in our global reputation for excellence. Our cutting-edge solutions deliver efficient and sustainable oil extraction, meeting the demands of industries worldwide.

- What is peanut oil extraction?

- Peanut oil extraction usually refers to two different methods: expeller pressing and solvent extraction. These two methods usually are used together. Peanut oil expeller is a little similar to the meat grinder nowadays.

- What is the history of solvent extraction in India?

- Solvent Extraction in India was started in 1945. It had to struggle for more than 20 years to establish itself. 1n the 1960’s there was a crisis in coconut oil extraction industry in Kerala. After conversion from wooden ghani’s to rotaries, the cost of the production had increased considerably.

- What is the largest solvent extraction plant in the world?

- Plans have now been announced for the construction of the largest solvent extraction plant in the world to be designed by The Power-Gas Corporation for Nchanga Consolidated Copper Mines Ltd, at Chingola in Zambia. This plant will have a throughput of 12,000 gallons per minute of leach liquor with a copper content in excess of 60,000 annual tons.

- Who makes peanut oil in South Africa?

- Amanah Oil is currently the Premium producer of Peanut Oil in South Africa. Setting up and running a small-scale cooking oil business – 6 – About the authors Barrie Axtell is a British food technologist with over 30 years’ experience working in Africa, Caribbean, Asia and Latin America.