high-tech small cold press soybean in lesotho

- Usage: Soybean Oil

- Type: Soybean oil seed extraction

- Production Capacity: 100%Soybean oil seed extraction

- Model Number: Qie

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Certification: CE/BV/ISO9001

- Raw material: Soybean Seed

- Name: Soybean oil seed extraction

- Application: Oil Pressing

- Common capacity: 1-2000TPD

- Warranty: 1 years

- Character: semi-auto, automatic

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Advantage: High Oil Yield

- Function: press Soybean/solvent extraction

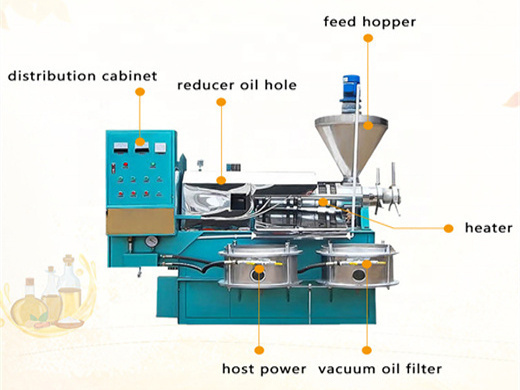

Our small cold oil press machine "oelwerk 100s inox" is a great oil press for you and your business. In this video we will show pressing of soy bean seed wit...

This would undoubtedly be due to the high TPC amounts of lentisk cold-pressed oil (83.17 mg GAE/100 g) which manifested an antioxidant activity higher than that of soybean oil. According to the study of Karoui et al. (2020) , the oil of Pistacia lentiscus seeds seemed to be a good source of antioxidant agents (phytosterols and tocopherols).

Cold pressed soybean oil

- Usage: Other

- Production Capacity: 1-50 Kg / H

- Voltage: 220 - 240 Volt

- Dimension(L*W*H): 840*240*540 mm

- Weight: 65 KG

- Warranty: 2 years

- Oil type: Soybean Oil

- Thermostat: Temperature Control 600 Watt

- Gear Box: Helical Shaft Gear

- Energy Consumption: 400- 1500 Watt/Hour

- Motor Power: 1.5 kW

- Raw material: STEEL

- After Warranty Service: Spare parts

Cold pressed soybean oil consists of different lipid and lipid derivatives groups such as neutral lipids, polar lipids, phytosterols, phenolic compounds, tocopherols (mainly γ- and δ-tocopherol), and hydrocarbons (squalene). γ- and δ-tocopherols are well-known antioxidants. Relatively high levels of essential fatty acids (linoleic and.

Kania et al. (2004) reported that solvent extraction of soybean oil yielded higher total tocopherols content (1448 mg/kg) than cold pressing (1358 mg/kg), and the refining process led to the loss of α-tocopherol by 37%, β-tocopherol by 56%, γ-tocopherol by 17%, and δ-tocopherol by 34% in solvent-extracted soybean oil.

The difference between pressed soybean oil and solvent

- Usage: edible oil

- Production Capacity: 200tpd oil press machine

- Model Number: various edible oil press

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales Service Provided: Overseas service center available

- Keywords: Home use manual soybean oil expeller equipment/oil press

- Name: Home use manual soybean oil expeller equipment/oil press

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: edible oil

- oil rate: 20%-98%

The pressed soybean oil is good in color, aroma and taste and retains various nutrients. While the solvent extracted oil is colorless and tasteless. Most of the nutrients are destroyed after processing. 3. Different requirements on materials “Pressed soybean oil” is made by pure physical pressing method, retaining the original flavor of.

The vegetative growth period (? 0.52 ± 0.24 days decade ?1) and whole growth period (? 1.32 ± 0.30 days decade ?1) of soybean were shortened, but the reproductive growth period (0.05 ±.

Progress and Prospects of the Molecular Basis of Soybean Cold

- Usage: small scale screw press Soybean oil machines

- Type: small scale screw press Soybean oil machines

- Production Capacity: 10T/H

- Model Number: PM-99

- Voltage: 380v/415v

- Power(W): As per capacity

- Dimension(L*W*H): As per capacity

- Weight: As per capacity

- Certification: ISO9001, CE, BV

- Project name: small scale screw press Soybean oil machines

- Phosphoric acid: 2~3kg/T oil

- Waste bleaching earth oil content: <35%

- Electric consumption: 28kwh/T oil

- Deodorization loss consumption: ≤0.5%

- Crude oil: Vegetable oil

- Steam consumption: 450kg/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Circulating water cooling water yield: 150m³/H

- cooling water: 13~28℃

Cold stress is a major factor influencing the geographical distribution of soybean growth and causes immense losses in productivity. Understanding the molecular mechanisms that the soybean has undergone to survive cold temperatures will have immense value in improving soybean cold tolerance. This review focuses on the molecular mechanisms involved in soybean response to cold. We summarized the.

Thus, cold-pressed soybean cake (CP-SBC) is increasingly becoming available for livestock feeding. However, the use of CP-SBC in formulating pig feeds is limited by the presence of trypsin inhibitor ( TI ) since during the cold pressing process, unlike during conventional solvent extraction, the seeds are not subjected to an adequate amount of.

Quality and chemical stability of long-term stored soy

- Usage: Soybean Oil

- Type: For Soybean Oil refinery usage

- Production Capacity: 100-500 ton

- Model Number: JXPL 1252

- Voltage: 380V 440V

- Power(W): As Soybean Oil refinery output every day

- Dimension(L*W*H): Depend on Soybean Oil refinery capacity

- Weight: As Soybean Oil refinery output

- Certification: ISO9001

- Item: Soybean Oil refinery

- Material: Stainless steel

- Rate of Soybean oil extraction: 40-53%

- Grades of Soybean oil: one grade ,two grade ,three grade ,

- Method of extracting Soybean: Pre-press then leaching

- Oil in the cake after press: 12-13%

- Oil in the cake after extraction: 1%

- Solvent residual after desolventizer: <300ppm

- Distillation range: 68-75℃

- Payment: l/c t/t

Fig. 1 shows the overlapping of native cold-pressed soybean (SN), canola (CN) and sunflower (SFN) spectra of the lipid fractions between 0.2 and 5.6 ppm, together with the enlargement of some of their main signals. Table 1 depicts the assignment of the signals shown in Fig. 1, the type of protons that generate the signal, and their chemical shifts.

Cold pressing. Another soybean oil extraction technology is cold pressing. This process involves pressing the soybean flakes at low temperatures (below 60°C) to extract the oil. Cold pressing is a gentle process that preserves the natural flavor and nutrients of the soybeans. Cold-pressed soybean oil is often used in specialty food products.

- Why is Lesotho a major exporter of textiles?

- Lesotho has taken advantage of AGOA to become one of the largest exporters of garments to the United States from Sub-Saharan Africa. It is ranked number two in terms of value of goods exported under AGOA and number three in terms of volume of goods exported primarily in textiles. Exports reached $ 333.7 million in 2021.

- What is the main crop in Lesotho?

- Only 11% of Lesotho’s land area is arable, but less than 1% has high potential. Most cultivated land is in the western lowlands. The principal food crop is corn. Main agricultural production in 2004 included (in tons) corn, 150,000; sorghum, 46,000; wheat, 51,000; dry beans, 8,000; and vegetables and melons, 18,000.

- Why is LNDC seeking investors for a knit fabric mill in Lesotho?

- The LNDC is seeking investors for a knit fabric mill in Lesotho Given the huge demand for knit fabrics in Lesotho and surrounding SADC member countries. In 2019, Southern Africa imported $1.5 million worth of knit fabrics; Lesotho imported $96 million in knit fabric.

- Does Lesotho have a duty free market?

- With one exception, the factories import all the raw materials they use to make garments, which means opportunities exist for other upstream industries. Beyond the U.S. market, Lesotho’s products enjoy duty free access to SACU and SADC countries, with a total population of 277 million.