20tpd peanut oil extraction plant in johannesburg

- Usage: Peanut Oil, Cooking Oil

- Production Capacity: 50-60 TPD

- Voltage: 100 HP

- Dimension(L*W*H): 3505t1820t1981

- Weight: 12000 KG

- Warranty of core components: 5 years

- Core Components: Motor, Bearing, Gearbox

- Oil type: Peanut Oil

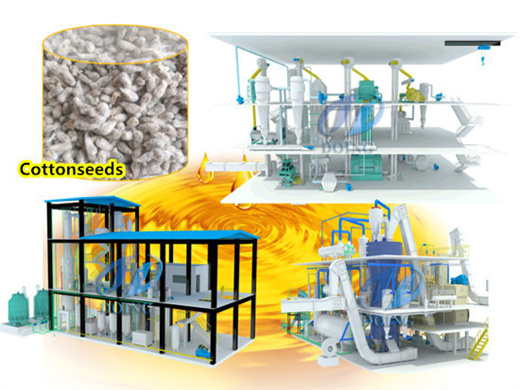

- Extraction of Oilseeds: Peanut ,Cotton,Peanut,Peanut ,Peanut Kernel ,Peanut

- MOTOR: 100 HP

- CAPACITY: 50 Tons/Day

- Model Number: VIRAAT-500

- After Warranty Service: Spare parts

- Certification: ISO / CE/ D&B

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Fragrant Peanut Oil Production Line. The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical.

Groundnut Oil Press Peanut Oil Extraction Plant - Vegetable oil processing machine oil pess and oil refinery - Oil Mills Oil Refinery Machine

- Usage: Peanut Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 3.5-50kg/h

- Voltage: 220V

- Dimension(L*W*H): 360*155*310mm

- Weight: 7 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Raw material: Peanut

- Product name: mini cold oil press machine

- Keyword: Peanut mini cold oil press machine

- Press type: screw type

- Function: press oil

- Quality: High-Quality

- Color: Sliver

- Model: X8S

- Use for: home use

- Delivery: fast delivery

Groundnut Oil Press Peanut Oil Extraction Plant Section Introduction: We can provide the equipments to process different capacity of peanut groundnut They bring unrivalled experience to bear in producing accurate drawings detailing foundation loadings, building dimensions and overall plant layout designs, tailor made to

1. The pressing parts of the mini oil mills ( 5-20TPD )-. After a lot treatment from the oil seeds, the raw material is sent to the pressing workshop, where the oil is extracted from the seeds and nuts. The mini oil mill connects a series of tools in order to extract the oil, some of the tools are- screw elevator, screw press, cleaning sieve, etc.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut oil grinder

- Type: Peanut oil grinder

- Production Capacity: 20-2000TPD

- Model Number: PZ 100t/d Peanut oil extraction machine

- Voltage: 380v

- Power(W): 15kw

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 2-10t

- Certification: CE,BV,ISO

- Name: Peanut oil grinder

- Material: stainless steel and carbon steel

- Color: customerization

- Labor need: 1staff

- End product: crude oil and cake

- Raw material: Peanut

- Package: container special for Peanut oil grinder

- Delivery: within 60 days after the payment

- Payment: TT, L/C

- Residual: less than 1%

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

We provides complete solution for Batch & Continuous type Edible Oil Refinery Plant, capacity to design, build and supply Plants from 5 tonne to 500 tonnes per day Cooking Oil Refinery We present one of the most developed Cooking Oil Refinery Plant

Peanut Oil Press Machine, Soybean Oil Extraction Plant - Oil Press, Oil Refinery Machine, Cattle Feed Plant Soybean Oil Extraction Machine,Oil

- Usage: Peanut Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Model Number: lp088

- Voltage: 220V

- Power(W): 5.5kw

- Dimension(L*W*H): 46*32*36cm

- Weight: 130kg

- Certification: ISO9001

- Product name: Portable screw press machine for oil production

- Item: Vertical Oil Press

- Advantage: Energy Saving

- Warranty: One Year

- Function: Hot Press

- Feature: Multifunction

- Product: Oil Reach

- Section: Pressing Section

- Application: Oil Production Line

- Use for: Vegetable Cooking Oil Pressing Machine

Oil Press Machinery We Are Distinguished Manufacturer And Service Providers For The Turnkey Solutions To Setup Oil Mills Projects. Right From Designing To Fabrication With Onsite Installation And Commissioning Of Screw Oil Press Machine, Oil Expeller, Oil

We can provide you the turn key project of the whole peanut oil extraction plant from 20 to 2000TPD . As manufacturer of peanut oil extraction plant, we can offer whole line or parts of peanut oil extraction plant with general capacity from 10TPD to 6000TPD. For special capacity, our engineers can also help you design and install workshop.

Comparison of cold-pressing and soxhlet extraction systems for bioactive compounds, antioxidant properties, polyphenols, fatty acids and

- Usage: Make essential oil

- Type: Steam distillation extractor

- Production Capacity: 1-100T/DAY

- Voltage: NA

- Dimension(L*W*H): 480*480*560mm

- Weight: 9.8 KG

- Core Components: Pressure vessel

- Oil type: ESSENTIAL OIL

- Raw material: Flowers herb roots plants leaves etc.

- Name: Essential Oil Distillation Equipment

- Output: 2-4kg/batch

- Function: Make Essential Oil

- Application: Vacuum Distillation Flowers Herb Roots Plants

- Advantage: Energy Saving, Simple Operation

- Material: 304 Stainless Steel

- Color: Silver

- Item: Essentials Oil Steam Distillation Equipment

- Feature: High Oil Yield Efficiency

The palmitic acid contents of cold pressed nut oils ranged between 4.87 (almond) and 9.45% (peanut), whereas those of soxhlet extracted nut oils ranged between 4.13 (almond) and 8.97% (peanut). Similarly, oleic acid contents of cold pressed oils were found between 19.88 (walnut) and 69.43% (pecan) while those of oils obtained by soxhlet extraction were minimum 19.07 (walnut) and maximum 68.53%.

What’s Inside the eBook. In this guide to peanut oil, we’ll examine the history of peanut production, explain how peanuts are processed into oil, and discover peanut oil’s diverse product applications as we explore this market’s global growth potential. The upstream processes of harvesting, cleaning, drying, and storing peanuts are.

- Who makes peanut oil in South Africa?

- Amanah Oil is currently the Premium producer of Peanut Oil in South Africa. Soybean oil is a vegetable oil extracted from the seeds of the soybean. It is one of the most widely consumed cooking oils. Being one of the drying oils, it is also used as a base for printing inks and oil

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What are the different methods of peanut oil production?

- Currently, there are two main methods of peanut oil production: a) Traditional Pressing (Mechanical Method): In this method, a peanut oil press is utilized to squeeze out the oil from the peanuts. The mechanical force applied through pressing allows the oil to be extracted effectively.