typeof extractor for leaching of peanut oil in lusaka

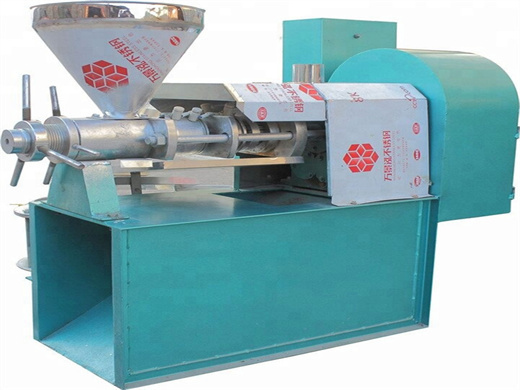

- Model Number: OI50

- Type: Peanut extruder machines

- purpose: Peanut extruder machines

- Description: high oil yield

- Material: Stainless steel

- color: fresh bright

- smell: original Peanut oil flavor

- original: china

- technology: new technology

- cetificates: CE/BV/ISO9001

- type: cold and hot press

- oil content: 12%-18%

The peanut oil produced with the leaching method is generally needed to be brought to the refinery workshop for refining treatment before being canned and packaged. 1. Leaching Procedure. The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil.

Extraction is a process for the separation of one or more components through intimate contact with a second immiscible liquid called a solvent. If the components in the original solution distribute themselves differently between the two phases, separation will occur. Separation by extraction is based on this principle.

Pressing, cold pressing and leaching of edible oil

- Type: Seed Roaster

- Voltage: 220/110V

- Dimension(L*W*H): 57cmX18cmX31cm

- Weight: 13.5KG

- Keywords1: Household oil expeller machine

- Keywords2: Peanut oil press

- Keywords3: avocado oil extraction machine

- Keywords4: nut & seed oil expeller oil press

- Keywords5: High approved household oil press machine

- Keywords6: Edible Oil Press Machine

- Keywords7: Peanut oil expeller

- Keywords8: Peanut oil press machine

- Keywords9: hot selling household oil press

- Keywords10: cooking oil machin

- Certification: CE

The peanut oil standard drafted by the National Grain Bureau has been implemented, and the old standards formulated in 1986 and 1988, which are currently used in China, have been removed. The new standard stipulates that: pressing peanut oil and leaching peanut oil should be labeled “squeezing” and “marking” in the product label. Leaching.

Because there is no bend section, the overall height of the chain extractor is much lower than that of the ring extractor. Ring extractor The biggest characteristic of annular leach is that the material can turn when entering the lower layer from the bending section, so that the material leaching is more uniform and thorough, the material layer is shallow, the wet meal contains less solution.

Solvent Leaching Oil Plant: Loop Type Extractor - Fotma

- Supply Type: OEM/ODM

- Type: Peanut Oil, Pure Carrier Oil

- Model Number: SFF

- Purity: 100 % Pure

- Usage: Cosmetic Industries

- Service: OEM ODM Private Label

- Sample: Freely Provided

- Material: Pure Natural Plant Extracted Oil

- Application: Aromatherapy Beauty Spa Aroma Diffusser

- Fragrance: Custiomized

- Function: Relaxing Massage Moisturizer Softener

- Appearance: Pale Yellow Liquid

Solvent leaching is a process to extract oil from oil bearing materials by means of solvent, and the typical solvent is hexane. The vegetable oil extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking.

5-Hydroxymethylfurfural (HMF) was extracted from peanut oil by liquid?liquid extraction procedure and determined by HPLC system as described by Durmaz and G?men . 0.5 g of oil was mixed with 1 ml of methanol (70%) in Eppendorf tube for analysis. The mixture was vortexed for 1 min and centrifuged at 10,000 rpm for 5 min.

Water Leaching Method to Extract Oil Plant Products

- Usage: Peanut,Peanut processing machine

- Type: Peanut,Peanutprocessing machine

- Production Capacity: 30kg-30t/day

- Model Number: oil press machine for sale

- Voltage: 380V or designed by your needs

- Power(W): Depend on the machine you choose

- Dimension(L*W*H): Depend on the machine you choose

- Weight: Depend on the machine you choose

- Certification: CE and ISO

- Item: multi-purpose cold press oil expeller machine

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Steel type: MiId steel and SS

- Raw materials: Peanut,Peanut

- Fina product: Salad oil

- Processing method: Machanical press

- Handling capacity: according to custoemer design

- Model type: Continuous

- Main market: Africa, Aisa

A water leaching method to extract plant oil, plant crude protein, and plant fiber comprising the following steps: (1) Preparing the raw material: a quality oil plant is selected as the raw material for oil extraction; (2) Rinsing: the select oil plant is rinsed by manual or by machine; (3) Stripping and Crushing: a dedicated machine is.

Ultimately, ultrasonic cavitation fields need monitoring and analyzing during the oil extraction and the synergistic relationship between the physical fields and cavitation associated with the oil oxidation could be built on this basis. Compared with other plant oils, oxidation of the peanut oil is easy to occur.

Processes | Free Full-Text | Defatting and Defatted Peanuts

- Usage: Peanut Oil press machine, Peanut Oil press machine

- Type: Peanut Oil press machine

- Production Capacity: Peanut Oil press machine

- Model Number: 1-200T/D

- Voltage: according your requirement

- Power(W): according the capacity of Peanut oil production equipment

- Dimension(L*W*H): according the capacity of Peanut oil production equipment

- Weight: according the capacity of Peanut oil production equipment

- Certification: BV and CE certification

- solvent:

- residual oil in cake: 1%

- extractor type: rotocel extractor

- Solvent consumption: ≤ 3Kg/T (6 #solvent oil)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Power consumption: ≤ 15KWh/T

- steam consumption: ≤ 280Kg/T (0.8MPa)

- Finished meal moisture: ≤ 10-13% (adjustable)

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment)

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- How can aqueous enzymatic extraction improve the function of Peanut proteins?

- Discuss extraction methods, modifications and applications of peanut proteins. Aqueous enzymatic extraction can efficiently separate oils and peanut proteins. The functionality of peanut proteins was significantly improved after modification. Native and modified peanut proteins can be used for a variety of purposes in foods.