top sales price coconut oil producing machine in zimbabwe

- Usage: manufacture of virgin Coconut oil

- Type: manufacture of virgin Coconut oil

- Production Capacity: 100%manufacture of virgin Coconut oil

- Model Number: manufacture of virgin Coconut oil

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Certification: CE ISO BV SGS

- Item: Manufacture of virgin Coconut oil

- Raw material: Coconut

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

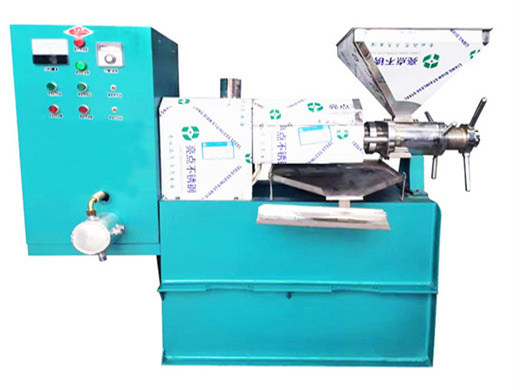

Our YZS coconut oil pressing machine is a screw type mechanical expeller press featured of easy operation and high efficient. You may use the machine to process both copra and virgin coconut. It is also suitable for making oil from other seeds or nuts, e.g. peanut, sesame seeds, soybean, etc. Screw Oil Press.

We manufacture virgin oil press machine with the help of our skilled manpower using best quality material. It is easy to operate and maintain, making it a top choice for small-scale oil making commercial workshops. The virgin coconut oil expeller mainly consists of a screw shaft, barrel, hopper, oil and cake output.

Small Coconut Oil Extraction Production Machine Starts

- Press Materials: Coconut, All seeds

- Press Series: Second

- Customized: Customized

- Name: Oil Presst Oil Press Machine Oil Expeller Oil Extr

- Function: Oil Processing Machinery 100-150kg/H

- Usage: Hot Cold Oil Press

- Raw material: Coconut

- Raw Material2: Coconut Avocado Coconut Fruit

- Raw Material 3: Automatic Coconut Pepper Coconut Coconut

- Raw Material 4: Coconut Pepper

- Squeeze Method: Cold Pressing and Hot Pressing

- Craft: Screw Oil Press and Hydraulic Oil Press

- Transport Package: Plywood Case

- Specification: 1000mm*538mm*1050mm

- Production Capacity: 6000set Per Month

Mechanical Coconut Oil Extraction Process: the dry coconut with 10% ~ 12% moisture is transported to the automatic scale to remove the broken iron through the magnetic chamber, and is ground into particles of about 0.3 cm in diameter, and the particles are pressed into a thin sheet to enlarge the surface of the dried coconut oil extracting.

A coconut oil making machine, also known as a screw oil press, is a professional solution for coconut oil extraction. Inquiry. Coconut oil is white or light yellow fat, extracted from copra, namely the dried white flesh of coconuts. Coconut trees grow in the tropical islands or along the continental coast. Copra contains 65%-74% oil and 4%-7%.

CoCoMaN Coconut Machines

- Type: Tile Forming Machine

- Tile Type: Steel

- Production Capacity: 15 m/min

- Voltage: 380V

- Weight: 2000 kg

- Rolling thinckness: 0.2-1.0mm

- Feeding width: 300MM

- Warranty of core components: 2 years

- Core Components: Pressure vessel, Motor, Other, Bearing, Gear, Pump, Gearbox, Engine, PLC

- Product Name: roll forming machine roller slats machine manufacturer price for sale

- Machine Size: 5800mm*1600mm*1800mm

- Frame Materials: 350H steel

- Diameter: 80mm

- Forming Shaft: Material 45# quenched and tempered

- Cutting System: Hydraulic Cutting

- Main Engine power: 4 KW with cycloidal reducer

- Electric tension: 380V 50 Hz 3 Phase or as your requirements

- Hydraulic oil: 40# hydraulic oil

- Material of cutting table: Cr 12 mould steel with quenched treatment

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, Nigeria, Ghana, Papua New Guinea, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico. Ask Us.

2. Main parts of the copra oil expeller adopt high-quality alloy steel and are hardened, sturdy and durable. 3. Coconut oil press machine integrates the function of cooking and can adjust the moisture content and temperature of oilseeds to achieve better-pressing effect, 4. Automatic and continuous operation, convenient to manage, saving labor.

Coconut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Coconut Oil

- Production Capacity: 45 sets per year

- Model Number: QI'E-30

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Certification: CE/ISO9001/BV

- usage: Coconut bean oil processing line

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

- Name: small scale Coconut bean oil processing line

- Function: Coconut bean oil processing line

Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business: Boiler. Copra Cutter. Copra Dryer. Cooker / Kettle. Copra Oil Expeller Machines. Crude coconut oil storage tanks. Oil Filter Press Machines. Bucket Elevator.

Virgin coconut oil is a useful substance in our daily life. It contains a high percentage of lauric acid which has many health benefits. The current industry has developed several methods to extract the oil out from the coconut fruit. This review paper aims to highlight several common extraction processes used in modern industries that includes cold extraction, hot extraction, low-pressure.

Virgin Coconut Oil Market Size & Growth | Forecast [2021-2028]

- Usage: Coconut Oil, All kinds of oil seeds

- Production Capacity: 100TPD

- Voltage: 220/380

- Dimension(L*W*H): 1400*860*1260

- Weight: 280 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- Name: screw oil press machine avocado oil extraction machine

- Product name: Oli Press Machine

- Function: Making Edible Oil

- Application: Screw Oil Expeller

- Raw material: Coconut

- Advantage: Energy Saving

- Material: 304 Stainless Steel

- Color: Customer Required

- Capacity: 750kg/h

- Keyword: Machine Oil Press

The global virgin coconut oil market size was USD 2.11 billion in 2020. The market is projected to grow from USD 2.24 billion in 2021 to USD 3.69 billion in 2028 at a CAGR of 7.35% during the 2021-2028 period. The global impact of COVID-19 has been unprecedented and staggering, with witnessing a positive impact on demand across all regions amid.

Virgin Coconut Oil Production Machinery by Gem helps in production of VCO to meet prescribed standards and to be suitable for human consumption. Gem is supplying machines to Phillipines, Srilanka, Indonesia and Fiji for production of Virgin Coconut Oil. Gem manufactures small scale to large scale virgin coconut oil machinery.

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?

- What is coconut oil machine?

- This unit of coconut oil machine is hot sale in recent years, expecially for small scale edible oil manufacturing business. It is a semi-automatic oil production machine set which connects each coconut processing equipment including sieving machine , cooke r, oil press and filter, and conveyors.

- What is the cost effective machinery for coconut oil extraction?

- For small or medium size coconut oil mill plant, the screw coconut oil expeller is the cost effective machinery in the from these aspects, including oil yield, investment cost, operation and maintenance. Coconut oil expeller machine is now the most commonly used machinery for coconut oil extraction.

- What are the components of coconut oil making machine?

- The main components includes heat conduction oil furnace, steam generator, deodorizing pot, decoloring pot, refining pot and leaf filter. It is suitable for 1-5TPD Refinery Plant. Hongde Machinery offers high quality coconut oil making machine and complete processing plant, capacity ranging from 1 TPD to 20 TPD.