sunflower seeds oil extraction plant in lagos

- Usage: For oil seeds and nuts

- Type: Cold & Hot Pressing Machine

Production Capacity: 20-2000TPD - Voltage: 380V

Power(W): standard - Dimension(L*W*H): standard

- Weight: standard

Certification: CE,ISO - Application: Sunflower Fruit Oil Making Machinery

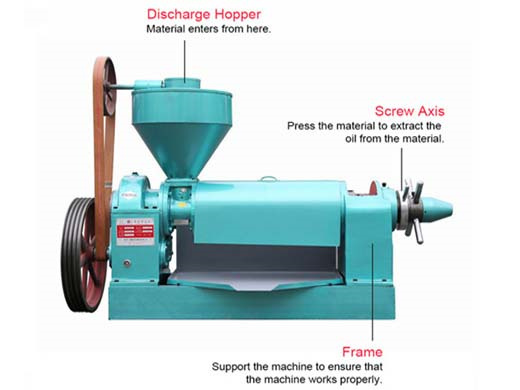

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: Sunflower seeds,Sunflower, oil Sunflower,etc.

- Production Capacity: 3-4kg, 400kg/h

- Voltage: 180-220v/50hz, 220v

- Dimension(L*W*H): 48*27.5*24CM

- Weight: 9.8 KG, 9.800kg

- Warranty: 1 Year, 12 Months

- Core Components: Motor

- Oil type: Sunflower Oil

- Material: Stainless steel

- Power: 200W

- Raw material: Oil Seeds

- Color: Gold

- Advantage: High Oil Yield

- Product name: Cold Oil Press Machine

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

Small Sunflower Cooking Oil Manufacturing Plant in Nigeria. Country: Ngeria. Capacity: 20TPD Oil Pressing & 8TPD Oil Refining. Raw Material: Sunflower Seeds. Main Oil Production Section: Sunflower Seeds Pretreatment, Sunflower Oil Extraction and Crude Sunflower Oil Refinery. Main Sunflower Oil Processing Methods: Mechanical Pressing and Batch.

Bioactive Phytochemicals from Sunflower (Helianthus annuus L

- Usage: Sunflower Oil

- Type: For cooking oil manufacturing machine usage

- Production Capacity: 50-3000TPD

- Model Number: JXSE169

- Voltage: 380v 440v

- Power(W): Capacity

- Dimension(L*W*H): As your machine ouput per day

- Weight: Depend on output

- Certification: ISO9001

- Item: Sunflower seeds processing

- Material: stainless steel

- Application: for all seeds extraction

- Output: as your request

- Residual oil in meal: less than 1%

- Solvent consumption: less than 2kg/t

- Power consumption: not more than 15KWh/T

- Process of refining: Degumming ,Decolorization

- Rate of Sunflower extraction: 38%- 42 %

- Payment: l/c t/t

The sunflower seed pressing procedure manages to transform about 25?33% of the initial seed weight into oil , while in chemical extraction, the average extracted oil yield is ~42% . As a result of this process, byproducts are generated with a high concentration of nutritional components, including high protein content, reaching around 40?50.

Stahl et al. [3] measured the solubility of sunflower seed oil in CO 2 at various pressure values (in the range between 150 and 700 bar) and at a temperature of 40 °C; the authors [3] performed extractions with hexane at atmospheric pressure and with CO 2 in the pressure range between 250 and 350 bar, obtaining an oil yield (kg oil /kg seeds.

The sunflower seeds oil extraction: the mechanism and

- Usage: Sunflower seeds oil refining plant

- Type: Sunflower seeds oil refining plant

Production Capacity: 1-100T/D - Voltage: 380V/440v

Power(W): 20-50KW - Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

Certification: ISO9001/BV/CE - Main export countries: Asia,Africa,Latin American,Malaysia...

Packaging: Glass Container,Plastic Container - Grade: first Grade

- refined oil: 1st grade

oil content: 35%-48% - fatty: 40~60.7

- protein: 20~37.2

phosphlipid: 1.25~1.75 - saccharides: 5~15

- Refiney type: Sunflower seeds oil refining plant

exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of.

Sunflower is a widely cultivated oilseed, and its oil presents high nutritional quality and economic value. The objective of this work was to use pulsed electric fields pre-treatment in sunflower seeds to obtain higher oil extraction yields and higher extraction kinetics of the process. Electrical treatments were carried out with different input electric fields up to 7 kV/cm. Evaluation of.

Recent industrials extraction of plants seeds oil used in the

- Usage: Sunflower oil

- Type: alibaba cotton seed cake oil solvent extraction machinery

Production Capacity: high - Voltage: 220V, 380V, or other

Power(W): depend on the capacity - Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

Certification: BV, CE, ISO9001, etc.... - Solvent in meal: ≤ 500ppm

Total volatile matter: ≤ 0.3% - Steam consumption: ≤ 280kg/t

- Residual oil in meal: ≤ 1.0%

Power consumption: installed capacity 320KW - Mechanical impurities: ≤ 0.2%

- Residual solvent: ≤ 300ppm

Urase activity: 0.05-0.25 (Sunflower meal) - Moisture in meal: 12~13% (adjustable)

- Solvent consumption: ≤ 4kg/t (No.6 solvent)

The sunflower seed oil has an immense number of fatty acids according to its climatic conditions. In cooler climatic conditions sunflower seed oil contains a higher concentration of polyunsaturated fatty acids particularly linoleic acid, while in warmer climatic conditions, the concentration of monounsaturated fatty acids especially oleic acid.

In this method, the seeds or nuts are hulled, crushed, added to water, and then boiled. Oils float to the surface, where they’re skimmed off and reserved. This is a slow and low-yielding process.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- What is sunflower seed processing?

- Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons ( FAO, 2013 ).

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- Voltage: 220V, 380V, or other

- Voltage: 380V/440v

- Voltage: 380V