sunflower seed oil solvent extraction plant in zimbabwe

- Usage: Filtration, Dewaxing, Winterization,Bleaching

- Production Capacity: upto 1000 TPD

- Voltage: N/A

- Dimension(L*W*H): N/A

- Weight: N/A

- Core Components: Motor, Pump, PLC, Gearbox

- Oil type: Sunflower Oil, Ricebran Oil

- Raw material: Sunflower, Rice-bran,Sunflower

- Application: Edible Oil Production, Dry Fractionation

- Feature: Smart fully automatic, Easy operation

- Advantage: Energy Saving, Low Utilities consumption,

- Operation: Automatic Operate,

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India

- Certification: ISO, CE, ASME, TUV

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

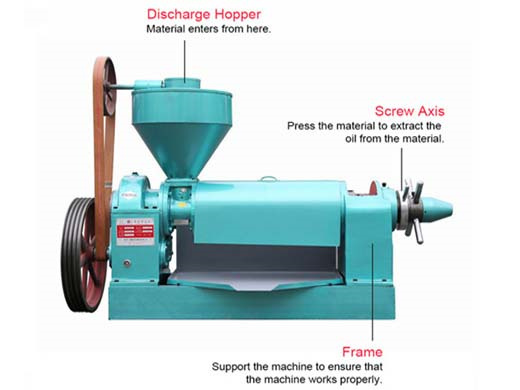

Sunflower Seed Preparation and Oil Extraction

- Usage: Sunflower Kernel Oil

- Type: Oil Extraction Machine

- Production Capacity: 15 - 33 Ton/day

- Dimension(L*W*H): Depends on the Model

- Weight: 0 KG

- Warranty: One Year warranty against manufacturer defect.

- Oil type: Sunflower Oil, Sunflower Kernel Oil

- complete Warranty Service: Video technical support

- After Warranty Service: Spare parts

- on site Warranty Service: Field maintenance and repair service

- Raw material: Oil Seeds

- Function: Making Edible Oil

- Product name: Oli Press Machine

- Application: Edible Oil Press

- Keyword: Small Capacity Oil Press Machine

- Used for: Edible Oil Making

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: Seed oil

- Type: Refining

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: ISO CE

- Name: Sunflower tree plants

- Raw material: Sunflower Seed

- Color: White

- Material: Steel

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

The extraction yield obtained by pressing was as low as 3% in the IASP-18 seeds and 37.5% in HA-89, while in the solvent extraction it was of the same order (~18 wt% on seeds extracted by pressing.

Sunflower Seed Solvent Extraction Plant Process

- Usage: Sunflower Oil, All kinds of oil seeds

- Production Capacity: 200KG/H

- Voltage: 380V

- Dimension(L*W*H): 2160*525*780mm

- Weight: 500 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Name: 6YL-95/ZX-10 Oil Press

- Applicatio: oil press machine

- Capacity: 200KG/H oil press

- Main power: 7.5kw

- Low oil residue in cake: less than 7%

- Matching machines: roaster,filter machine,conveyor etc

- working manual: we can supply

- Advantage: Energy Saving

- Company type: factory and manufacture

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Certification: CE,ISO

The most suitable temperature for the growth of sunflower seed is 20 27°C with abundant water. There are several varieties of seeds available consisting of 36% of Oil to 40% of oil based on cultivated area soil condition and species of the seed. The Oil extracted from sunflower seeds either by screw press or by solvent extraction process.

[Citation 10] The vegetable oils are rich sources of omega-6 FA, involving cotton seed oil, sunflower oil, corn, soybean oil, and safflower oil. In comparison, the omega-3 fatty acids are more abundant in linseed oil as well as canola and dark leafy vegetables like purslane, kale, collards, mustard greens, and spinach.

Extraction of sunflower oil using ethanol as solvent

- Core Components: PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Weight: 180 kg, 180kg

- Name: Oil Filter Machine

- Model: HLLY-63A

- Capacity: 1800L/H

- Machine dimension: 850*850*1100mm

- Power: 1.5kw

- Material: Ss 304 316 316l

- Voltage: 110-460v

Ethanol and isopropanol, absolute (ET0, IPA0) and hydrated with 6 and 12 water mass% (ET6, IPA12), were evaluated as solvents in the oil extraction from spent coffee grounds (SCGO).

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a.