sunflower oil solvent extraction plant equipment in lagos

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: Z1958

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

100-3,000TPD Palm fruit/Palm kernel pre-pressing. 50-500TPD Sesame preparation plant. 100-3,000TPD Sunflower seed preparation plant. 50-1,000TPD Rice bran preparation plant. 50-1,000TPD Peanut preparation plant. In addition, we also provide other oilseeds preparation plant, including coconut, linseed, niger seed, shea nut, copra, avocado and etc.

Sunflower Seed Preparation and Oil Extraction

- Usage: Sunflower oil plant seeds

- Type: Sunflower oil plant seeds

- Production Capacity: 100%Sunflower oil plant seeds

- Model Number: Sunflower oil plant seeds

- Voltage: 220V/380V/440V

- Power(W): 5.5-22KW

- Dimension(L*W*H): 48m*12M*15M(50tons)

- Weight: 50tons

- Certification: ISO9001

- Raw material: Sunflower Seed

- Name: Sunflower oil plant seeds

- Application: Food Industry

- Material: Carbon Steel Q235

- Application range: 100KG-100TPD

- Advantage: Simple Operation

- Use for: All kinds of oil seeds

- Character: Oil Processing Line

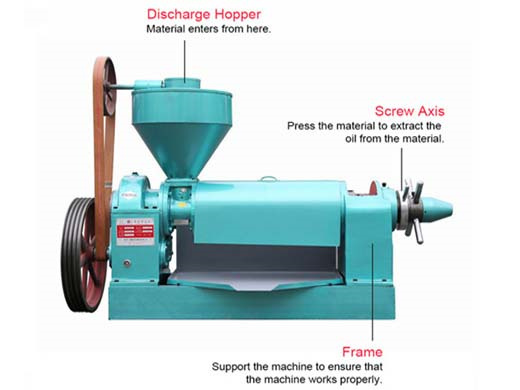

- Item: Edible Oil Press

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Sunflower Processing - Crown Iron Works

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: X1845

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

The seed is mechanically pressed (pre-pressed) to extract approximately half to three quarters of the available oil so that the solvent extraction can be run more efficiently. This is typical for seeds containing more than 20% oil. The solvent extraction process uses hexane or other solvents to wash the sunflower oil from the prepared flakes.

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Extraction of sunflower oil using ethanol as solvent

- Usage: Sunflower Oil

- Type: Refinery

Production Capacity: 30-300 tons - Voltage: 380V/3 phase

Power(W): According to capacity - Dimension(L*W*H): 1200*400*900mm3

Certification: CE & ISO, ISO-9001 and CE - Supplier type: Manufacturer

Manufacturing experience: 19 years - Handling capacity: 30-300 tons/24h

- Service life: 20-25 years

Materials: Crude oil - Final product: Edible/salad oil

- Production period: 55 days

Installation period: 60 days - Main market: Asia, Africa and Oceania

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

Home [www.slabmarkgroup.com]

- Usage: For Sunflower edible oil extruder usage

- Type: For Sunflower edible oil extruder usage

- Production Capacity: 50-3000TPD

- Model Number: JXSE 475

- Voltage: 380v 440v

- Power(W): As Sunflower edible oil extruder output every day

- Dimension(L*W*H): As edible oil extruder ouput per day

- Weight: Depend on edible oil extruder output

- Certification: ISO9001

- Item: edible oil extruder

- Material: stainless steel

- Application: for all seeds extraction

- Output: as per customer requestment

- Residual oil in meal: less than 1%

- Solvent consumption: less than 2kg/t

- Power consumption: not more than 15KWh/T

- Process of refining: degumming ,decolorization ,deodorization , deacidification ,dewaxing

- Raw material: Sunflower Seed

- Rate of Sunflower extraction: about 18 %

Welcome. Slabmark Nigeria Limited is a privately owned limited liability company with 100% indigenous share holding. The company was incorporated on the 11th December 1997 and commenced operations in March 2000 with the commissioning of a 100 tonnes per day Solvent Extraction Plant. The registered office is Km89 Old Lagos, Ibadan Oyo State.

The seed is mechanically pressed (pre-pressed) to extract approximately half to three quarters of the available oil so that the solvent extraction can be run more efficiently. This is typical for seeds containing more than 20% oil. The solvent extraction process uses hexane or other solvents to wash the sunflower oil from the prepared flakes.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- Can sunflower oil be used as a substitute for organic solvents?

- Likewise, Li et al. applied sunflower oil as a substitute for organic solvents in carotenoids extraction from fresh carrots using an ultrasound-assisted extraction (UAE) process [ 82 ]. This procedure was compared with conventional solvent extraction (CSE) using hexane as the solvent.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- How is sunflower oil extracted?

- A volatile hydrocarbon like hexane is used as a solvent to extract the oil. The harvested sunflower oil seeds are passed over magnets to subtraction any metal traces, and other impurities are getting rid off by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to get pure seeds.

- Voltage: 380V/3 phase