sunflower oil solvent extraction plant consumption in lusaka

- Type: TIG Welders

- Core Components: Motor

- Arc Current: standard

- Pulse Frequency: standard

- Pilot Arc Current: standard

- Rated Duty Cycle: standard

- Motor Type: servo

- Dimensions: customized

- Usage: arc welding machine

- Voltage: 380

- Power: standard

- Weight (KG): 5000 KG

- Welding efficiency: 280-500D. I/8hrs

- After Warranty Service: Spare parts, Field maintenance and repair service

- Local Service Location: Malaysia

- Certification: ISO9001: 2008

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Sunflower meals can be processed from whole, dehulled, or decorticated seeds through the mechanical or solvent extraction method, and these determine the quality of the resulting sunflower products. Sunflower meal is the largest by?product obtained after the oil extraction process from sunflower seeds in an industry.

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

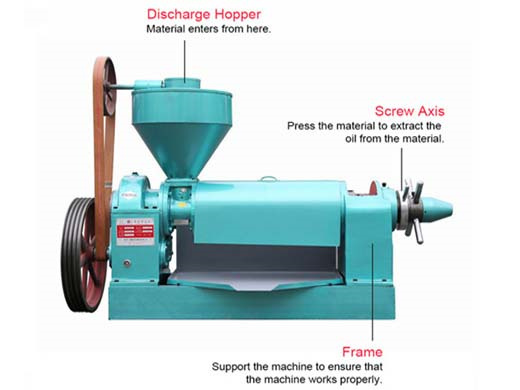

- Usage: Sunflower oil

- Type: Sunflower oil press machine

- Production Capacity: 10T-3000T/D

- Model Number: DT

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to Sunflower oil processing capacity

- Certification: ISO9001/CE/BV

- Item: Sunflower oil fractionation plant

- , long term technical support

- Supply scope: EPC/Turn-key Project

- Plam oil extraction method: Press method

- Acid value: depend on the Sunflower fruits quality

- Color of crude Sunflower oil: brown red

- Color of machine: depend on your requirement

- Oil content in Sunflower fruit: 22%

- Sunflower oil refining machine: available

- Raw material: Fresh Sunflower

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: turkey standard Sunflower oil processing machine

- Type: turkey standard Sunflower oil processing machine

Production Capacity: 1-100TPH - Voltage: 220V/380V

Power(W): 18.5KW - Dimension(L*W*H): 2000x1400x1850mm

- Weight: 15TONS

Certification: ISO CE BV SGS - equipment mame: turkey standard Sunflower oil processing machine

Raw material: Sunflower Seed - markets available: Africa, America, Asia

- rsidual: less than 0.6%

warranty: 1 year - Function: making Sunflower oil

- shipping: supplied

insurance: supplied - advantage: lower costs, energy saving

- technology: latest

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

Extraction of sunflower oil using ethanol as solvent

- Model Number: JN-30

- Usage: nuts

- Type: nut roasting oven

- Power Source: Electric

- Voltage: 380V

- Power(W): 30KW

- Weight: 1ton

- Dimension(L*W*H): 10680*840*1750mm

- Certification: CE

- name: Tunnel roasting oven for seed nuts

- power input: 42KVA

- power output: 30KW

- temperature: 0~200C(adjustable)

- magnetron: Panasonic

- conveyor belt: Teflon

- type: tunnel conveyor belt type

Abstract. The ethanolic extraction of oil from sunflower collets was studied and compared with previous data where hexane was used as extraction solvent. First, the extractive power of ethanol was.

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Molecules | Free Full-Text | Leading Edge Technologies and

- Usage: oil extraction systems

- Production Capacity: 100% oil press machine

- Model Number: 6YL

- Voltage: 220V/380V/440V

- Power(W): 5.5~18.5KW

- Dimension(L*W*H): 1950*1300*1900, according to the capacity

- Weight: 950KG

- Certification: ISO9001/CE/BV

- Raw material: Sunflower Seed

- used for: oil extraction systems

- Application: Oil Pressing

- Common capacity: 80-600kg/h

- Warranty: One Year

- Character: oil press machine

- decoloring time: 15-20min

- Moisture: 3%

- residual oil in cake: 2%

The solvent extraction process has the advantage of a much higher oil yield (

Sunflower and soy oil were used as alternative solvents to study the effect of various parameters on the yield between ultrasound and conventional extraction, in which the optimal conditions for achieving maximum yield of carotenoids from pomegranate peels were 10:1 a, 30 min, 51.5 °C, 58.8% of amplitude level and sunflower oil solvent.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- How to extract sunflower oil?

- An ordinary method in extracting sunflower oil includes preparation of seed and mechanical extraction . Since no type of solvent and no other processing are involved in the production of cold-pressed oil, rather than filtering and pressing, it is more important for the market. …

- What are the kinetics and mechanism of sunflower seed oil extraction?

- The kinetics and mechanism of the extraction process investigated. It is shown that the process of extracting sunflower seed oil is complicated and include as intra-diffusion and outer-diffusion oil transfer is similar to extraction of target components from other seeds of plant material (amaranth, rapeseed, etc.).

- Can sunflower oil be used as a substitute for organic solvents?

- Likewise, Li et al. applied sunflower oil as a substitute for organic solvents in carotenoids extraction from fresh carrots using an ultrasound-assisted extraction (UAE) process [ 82 ]. This procedure was compared with conventional solvent extraction (CSE) using hexane as the solvent.

- Voltage: 220V/380V