sunflower oil solvent extraction plant best system in lusaka

- Usage: Sunflower Oil

- Production Capacity: 100%

- Model Number: 6120

- Voltage: 380

- Power(W): 11KW/380v/6level

- Dimension(L*W*H): 2050*1350*2000

- Weight: 1000kg

- Certification: CE ISO

- Model number: 6120RL

- Material: Stainless Steel SS304/316

- Application: Oil Pressing

- Feature: High Oilput

- Advantage: 36 Years

- Raw material: Sunflower Seed

- Capacity: 200-300kg/h

- Speed of press screw: 30-45r/min

- Residual oil rate: 6~7%

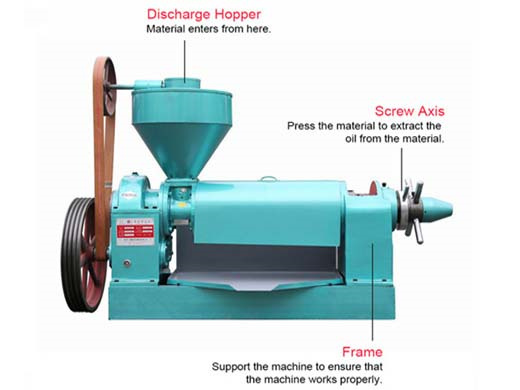

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Preparation. The first step in processing sunflower is to properly prepare the seed for oil removal. The seed is cleaned using magnets to remove metal and screening to remove impurities that can interfere with the process. The seed can be dehulled by cracking and removing the shell or can be sent to pressing with the shell still intact.

Extraction of sunflower oil using ethanol as solvent

- Usage: hot/fry press, cold/raw press, about 150 types oil crops expellers

- Type: oil press machinery, oil expeller, screw oil press expeller

- Production Capacity: 100kg/h

- Voltage: 380V, 380V

- Dimension(L*W*H): 2600*2100*2200mm

- Weight: 1480 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox, Sunflower oil processing machine

- Oil type: Sunflower Oil

- Main body motor power: 11~22KW

- Oil Filter power: 1.1~2.2KW

- Spiral Axes Rotation Speed: 90-150r/min

- Operation Quantity: 3.5-5.5t/24h

- Material: Stainess Steel

- Feature: Eco-Friendly

- Used for1: Sunflower Sunflower Sunflower

- Used for2: Sunflower Sunflower bean

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Make essential oil

- Type: Steam distillation extractor

- Production Capacity: 100kg/h-1000kg/h

- Voltage: NA

- Dimension(L*W*H): 480*480*560mm

- Weight: 9.800kg

- Core Components: Pressure vessel

- Oil type: essential oil

- Raw material: Flowers herb roots plants leaves etc.

- Name: Essential Oil Distillation Equipment

- Output: 2-4kg/batch

- Function: Make Essential Oil

- Application: Vacuum Distillation Flowers Herb Roots Plants

- Advantage: Energy Saving, Simple Operation

- Material: 304 Stainless Steel

- Color: Silver

- Item: Essentials Oil Steam Distillation Equipment

- Feature: High Oil Yield Efficiency

- After Warranty Service: Video technical support, Online support

- Certification: CE, ISO

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Plant oils can be extracted with various techniques based on different principles such as batch solvent extraction, [5] Soxhlet extraction, [6] mechanical pressing, [7] supercritical extraction.

Sunflower oil extraction plant

- Usage: Sunflower Oil, Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 20ton per day

- Voltage: 380v

- Dimension(L*W*H): 2750*1100*1830mm

- Weight: 1820 KG

- Core Components: Gear, Bearing, Gearbox

- Oil type: Sunflower Oil

- Name: Oil Press Machine

- Function: Oil Pressing

- Advantage: High Oilput

- Material: Carbon

- Quality: Top Level

- Color: Optional

- After Warranty Service: Video technical support

- Certificate: ISO9001

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

Since most solvent extractors are designed to handle soybeans, which only contain 20% fat by weight, these high-oil content sunflower seeds require pre-pressing before extraction. Solvent processors pre-press the de-hulled, flaked, cooked, and dried seeds in an expeller, reducing the oil content from 50% to about 20% so the material can be processed through an extractor designed for soybean.

Extraction of sunflower oil using ethanol as solvent | Request PDF - ResearchGate

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine, extract cooking oil

- Production Capacity: 100%

- Model Number: 6YL

- Voltage: 220V/380V/440V

- Power(W): 15KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 700kg

- Certification: CE&BV

- Power: Electricity/water/steam

- Raw material: Sunflower Seed

- Capacity: 2-2000TPD

- Certifate: ISO&BV&CE

- Operating: Easy operate

- Made in: China

- Color: According to customers

However, studies on oil partitioning or distribution in systems containing oleaginous solids and alcoholic solvents are scanty. Some such studies involve oil extraction from sunflower and cotton.

For vegetable oil solvents targeting to six major aroma extracts (i.e., linalool, estragole, eucalyptol, trans-anethole and limonene) from basil, refined sunflower oils was theoretically and experimentally proven as the most suitable solvent among ten vegetable oils [].

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- Can sunflower oil be used as a substitute for organic solvents?

- Likewise, Li et al. applied sunflower oil as a substitute for organic solvents in carotenoids extraction from fresh carrots using an ultrasound-assisted extraction (UAE) process [ 82 ]. This procedure was compared with conventional solvent extraction (CSE) using hexane as the solvent.