sunflower oil extraction plant in togo

- Usage: Sunflower Oil

- Production Capacity: 5-500 TPD

- Model Number: Z1905

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction.

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

The sunflower seeds oil extraction: the mechanism and

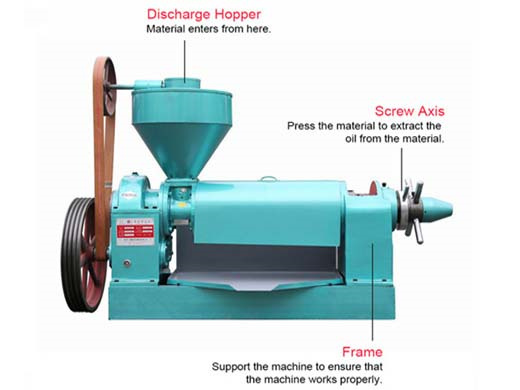

- Usage: hydraulic oil press machine

- Type: Cooking Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 800*950*1700mm

- Weight: 2000 KG, 2000kg

- Core Components: Motor, Pressure vessel, Pump, Gearbox, Sunflower oil press machine

- Oil type: Sunflower Oil press machine

- Name: Sunflower oil press machine

- Product name: Sunflower oil machine presser Sunflower oil processing plant

- Model: 6YZ-320 oil press machine Sunflower

- Barrel diameter: 320mm

- Max work pressure: 50MPa

- Outer dimension: 800*950*1700

- Moter power: 2.2kw

- Hearter power: 1.2kw

- After Warranty Service: Video technical support, Online support, Field maintenance and repair service

- Certification: ISO

For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of 97-98 %, the use

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Oilseed crop sunflower (Helianthus annuus) as a source of

- Usage: for oilseeds and Sunflower oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 20-2000T/day - Voltage: 380V

Power(W): 15KW - Dimension(L*W*H): standard

- Weight: 30tons

Certification: CE,ISO - Equipment Name: cotton seed oil refine machine

Machinery type: Large-scale and small-scale - Raw material: Sunflower Seed

- Application: Oil Production Line

Advantage: High Efficient - Color: Silver

- Function: Cold Press

Model: HT-2 - Item: Industrial Manual Oil Extractor

A single solvent can be used, but the maximum extract yield of the active plant components might be reduced; therefore, the combination of plant extraction solvents can be used to obtain the maximum yield of the plant extract. Oil extracted from sunflower seeds is considered healthy and can minimize the risk of cardiovascular disease.

Figure 1 represents schematically the main steps of sunflower oil extraction and refining. There are five main stages where there is a potential leak of minor components: Degumming, neutralization.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Sunflower Oil

- Type: Sunflower oil equipment

- Production Capacity: high

- Model Number: complete Sunflower oil processing plant

- Voltage: 220V, 380V, or other

- Power(W): depend on the capacity

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- Certification: BV, ISO9001, CE, etc..., BV, ISO9001, CE, etc..

- Product name: complete Sunflower oil processing plant

- Capacity: 1tpd-200tpd

- Use: oil refinery

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction. The advantage of the extraction method is the high degree of oil extraction of.

A review of phytochemistry, metabolite changes, and medicinal

- Usage: Sunflower OIL, All kinds of oil seeds

- Type: Oil Extraction Machine

- Production Capacity: 50-500kg/h

- Voltage: As per your local voltage

- Dimension(L*W*H): 1910*610*765 mm

- Weight: 420 kg

- Warranty: 1 year, 12 Months

- Certification: CE ISO

- Name: Sunflower Kernel Oil Press Machine

- Raw material: Avocado

- Function: Oil Pressing

- Application: Oil Production Line

- Advantage: Energy Saving Low Residual

- Color: Clients' Requirements

- After-sales Service: Provide Longlife Technical Support

- Package: Wooden Case

- Keep working: 24h

The sunflower (Helianthus annuus L.) seed and sprout is a ubiquitous crop with abundant nutrients and biological activities.This review summarizes the nutritional and medical importance currently recognized but under-researched concerning both seed and sprout highlighting the potential benefits of their phytochemical constituents including phenolic acids, flavonoids and tocopherols.

The seed is mechanically pressed (pre-pressed) to extract approximately half to three quarters of the available oil so that the solvent extraction can be run more efficiently. This is typical for seeds containing more than 20% oil. The solvent extraction process uses hexane or other solvents to wash the sunflower oil from the prepared flakes.

- Voltage: 380V