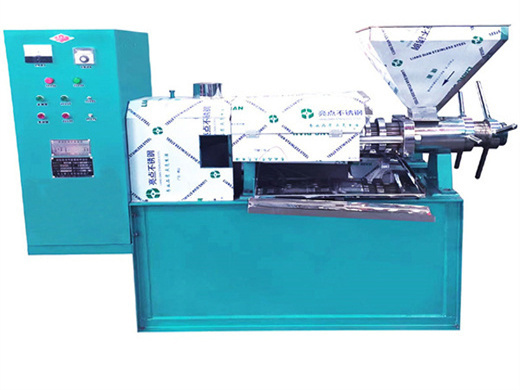

soybean crusher for oil fats press oybean cracker in togo

- Usage: Squeezing and extraction of oil and agricultural products

- Type: Oil Extraction Machine

- Production Capacity: ≥98%

- Voltage: 380V/50Hz

- Dimension(L*W*H): 2850*1850*3270mm

- Weight: 5000 KG

- Core Components: Gear, Gearbox, Squeezing part, Feeding system, Frame

- Oil type: Soybean Oil, Safflower seed Oil, Feeding system Oil

- Product name: screw oil press

- Advantage: Simple operation/high efficiency

- Raw material: Oil Seeds

- Keyword: Soybean Oil Solvent Extraction Equipment

- Function: Making Edible Oil

- Quality: Top Level

- Press type: Screw Hot

- Application 1: Grease production line/small and medium oil plant

- Application 2: For farms/ farm machinery/ agriculture machinery

Abstract. A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusher. In a modern and efficient extraction plant, a residual oil content ≤ 0.5% for soybean meal is expected.

Other products such as soy oil, meals, soy sauce, and tofu are manufactured through diverse processing technologies [22]. Moreover, with well-developed techniques, quality of soy protein can be improved through food processing: cooking, soaking, germination, extrusion, fermentation, protein concentration, and isolation.

Overview of the soybean process in the crushing industry - ResearchGate

- Usage: Soybean Oil

- Type: Cold & Hot Pressing Machine, Soybean kernel oil expeller machine

- Production Capacity: 10-5000T/D

- Model Number: DT-10030

- Voltage: 220V/380V/415V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Certification: ISO9001

- Raw material: Soybean Seed

- Function: Vegetable Oil

- Suitable for: Soybean, Cotton, Soybean,etc

An introductory overview of soybean crushing including different processes from oil extraction and refining to lecithin and meal preparation is presented by Demarco and Gibon (2020). Pilorgé and.

Soybean Crushing. Nearly 2 billion bushels of soybeans are crushed every year. During the crush process, soybeans are cracked to remove the hull and then rolled into flakes, which are then soaked in a solvent and put through a distilling process to produce pure crude soybean oil. After the oil has been extracted, the soybean flakes are dried.

Soybean oil lowers circulating cholesterol levels and coronary heart disease risk, and has no effect on markers of inflammation

- Usage: Soybean Oil

- Type: Complete production line

Production Capacity: 30-300TPD - Voltage: 380V / 3Phase

Power(W): According to your capacity - Dimension(L*W*H): 1200*400*900mm3

- Weight: According to your capacity

Certification: CE and ISO - Supplier type: Manufacturer

Manufacturing experience: 19 years - Function: Oil refinery

- Texture: Mild steel and SS

Capacity: 30-300TPD - Raw material: Soybean Seed

- Warranty: 1 year

Production cycle: 65 days - Installation period: 60 days

- Shipping terms: FOB Qingdao or Tianjin

Diets 30% total fat, 2/3 of fat from test fat: soybean oil or butter LDL-C, HDL-C, TG, Apo B SO ↓ LDL-C and Apo B vs. butter Zhang et al. [34] China Randomized, parallel, controlled feeding 60 M, ages 18?25 y 6 wk 30% energy from total fat, 75%?80% of total

INTRODUCTION. In the soybean industry, the term ‘crush’ refers both to a physical process as well as a value calculation. The physical crush is the process of converting soybeans into the by-products of soybean meal and soybean oil. The crush spread is a dollar value quoted as the difference between the combined sales values of the products.

History of Soybean Crushing: Soy Oil and Soybean Meal - Part 1 - SoyInfo Center

- Usage: Soybean Oil

- Type: Soybean kernel oil machine processing

Production Capacity: 1-3000T/D - Voltage: 220V ,380V

Power(W): According to your capacity - Dimension(L*W*H): 1200*400*900mm3

- Weight: According to the Soybean kernel oil machine processing capacity

Certification: ISO9001 & CE - Product name: Soybean kernel oil machine processing

Transparency: 500C transparent - Smell,taste: Smell and taste is good

- Color(133.47mm dispoable cuvettes): less thanY30R3.0

Moisture and volatile matter%: less than0.05 - Wastes%: less than0.05

- Melting point0C: 33-39

Acid value mgKOH/g: less than1.0 - Peroxide value mmol/L: less than 10

- Soybean Olein: high quality after Soybean kernel oil machine processing

During the 1940s and 1950s major advances were made in soy oil refining, which greatly increased its acceptability in cooking and salad oils, margarine, and shortening. Also during the 1940s, for the first time in history, the majority of the world's soybeans were crushed to yield oil and meal. 1950-1982 .

The amino acid composition of soybean proteins is close to that of animal protein, in particular the content of exogenous amino acids, i.e., phenylalanine, methionine, threonine, valine, isoleucine, leucine, tryptophan, and lysine. In the reference literature [ 1, 2, 17, 18 ], the following percent rates are reported of their contents in the.

Soybean, Protein, and Oil Production Under Stress

- Usage: Soybean bean oil making machine

- Type: Soybean bean oil making machine

- Production Capacity: 100%

- Model Number: Oils and fats refining equipment

- Voltage: 380V

- Power(W): According to different models

- Dimension(L*W*H): 1200*400*900mm3: 3-600 ton/24h

- meterials: Q304R

- payment terms: T/T

- service life: 12-18 years

- warranty period: 1 year

- delivery: a month

- color: according to customers' requirement

The soybean is a suitable source of oleic and linoleic acid; even if the soy oil is partially hydrogenated, it has 25% linoleic and 3% linolenic acid. It is, as previously mentioned, a good source of protein, oil, and carbohydrates. The rate of amino acids in soybeans is significant and is a complement to cereals.

Oil major Chevron plans to invest $600 million in two soybean crushing facilities owned by U.S. agricultural commodities trader Bunge Ltd, securing future feedstock for renewable fuels, the two companies said. The investment will result in a 50/50 joint venture, under the memorandum of understanding the two companies said they reached.

- What Aker is used in soybean crushing?

- Typical aker used in soybean crushing (Desmet Ballestra Group-Web site). Fig. 8. (a) Soybean akes; (b) Soybean expandates (Desmet Ballestra Courtesy). n-hexane but a mix of isomers with very similar properties.

- What type of Flaker is used in soybean crushing?

- Typical flaker used in soybean crushing (Desmet Ballestra Group-Web site). (a) Soybean flakes; (b) Soybean expandates (Desmet Ballestra Courtesy). A large solvent Reflex ® extractor (immersion/deep bed) in assembly phase (Desmet Ballestra Courtesy).

- What solvent is used to make soybean protein concentrate?

- It should be noted that other solvents may be required to produce different and specific products; for example, an alcohol-water mixture is used in an additional extraction step (after hexane extraction) to produce soy protein concentrate (or “SPC”) by removing the sugars from standard soybean meal ( Wang et al., 2004 ).

- What is soybean meal from the solvent extraction plant?

- Soybean meal from the solvent extraction plant is a mix of particle sizes; it is therefore necessary to undergo several additional process steps (meal sizing) to produce a nished fi product that meets trading rule size speci cations. fi The akes that have been shaped in the preparation plant enter the solvent extraction plant (Fig. 3).

- Voltage: 220V ,380V

- Voltage: 380V / 3Phase