small palm kernel corn oil press plant in kenya

- Type: Cold Press Machine

- Voltage: 380V

- Dimension(L*W*H): 3000*1250*3300mm

- Weight (KG): 300 kg

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Overseas service center available

- Color: white or other color

- Usage: woodworking for door

- Other name: woodworking cold press machine

- power: 4-5.5kw

- Max.pressure: 50t

- working plate size: 2500*1250mm

- Max.workpiece thickness: 1500mm

- Weight: 2100kg

- Power: 4-5.5kw

- After Warranty Service: No service, Spare parts

- Local Service Location: None

- Marketing Type: Other

- Certification: ISO9001/CE

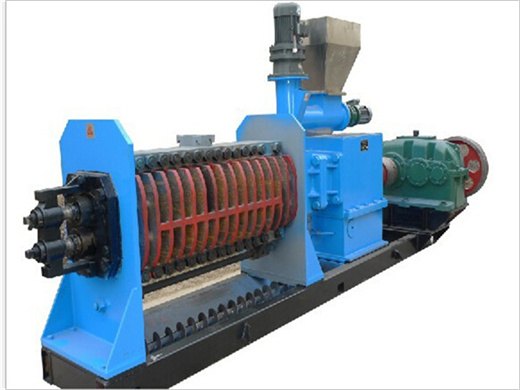

Palm Kernel Oil Mill Introduction. Automatic double-shaft palm kernel oil mill can squeeze out most of the oil from fresh palm kernels by the high mechanical pressure. Palm kernel oil extraction machine has a large processing capacity and high oil yield which is special for crushing palm kernels, and its service life is three times higher than.

The purpose of steaming is to destroy oil cells by temperature and water, denaturing protein, gathering oil, reducing oil viscosity and surface tension, adjusting elasticity and plasticity of billets, and passivating enzymes. Steaming and frying equipment in palm kernel oil production line is mainly steaming and frying pan. Pressing.

Palm kernel oil - Wikipedia

- Weight (KG): 1500

- Warranty of core components: 1 Year

- Core Components: PLC, Bearing, Gearbox, Motor, Pressure vessel

- Type: Rice making machine

- Application fields: Commercial catering, Snack food factory, Flour mill, Seasoning plant, Bakery, Palm oil factory

- Machinery Capacity: 80-400kg/h

- Machinery Function: Producing

- Feature: Automatic

- After Warranty Service: Provided

- Advantage: High Effieciency

- Packing: Wooden Case Packing

- Voltage: 380V/50Hz

- Final products: Rice

- MOQ: 1 Set

- Material: Stainless Steel 304/316

- Color: Silver

- Certification: CE ISO

Palm kernel oil. Palm kernel oil is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. [1] It is related to two other edible oils: palm oil, extracted from the fruit pulp of the oil palm, and Palm oil, extracted from the kernel of the Palm. [2]

For example, either single machine or production line are both for sale. Our palm kernel oil production line’s capacity is 10-100 tons per day and its residual oil rate is 5%, and we provide you with palm kernel oil production and refining process design, manufacture, installation, commissioning and after-sales service if it is needed.

Palm Kernel Oil Manufacturing Process With Flowchart - Hongde

- Usage: Transportation, Energy Generation

- Type: Biodiesel Production Plants

- Production Capacity: 10 to 1000 TPD

- Voltage: 115V/220V

- Dimension(L*W*H): 63*36*46cm

- Weight: 1000 KG

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Distillation Column

- Raw material: Palm, Palm Kernel

- Raw materials suitable: Fatty Acid Distillates, Waste Oil, Palm oil

- Application: Transesterification, FAME distillation, Glycerolysis

- Processing Types: Glycerin treatment, Bleaching, Deacidification, Washing

- Section: Methanol Rectification, Glycerin distillation, FAME bleaching

- Product name: B20, B100, FAME, Pharma grade Glycerin, Industrial Grade glycerin

- Capacity: upto 1000 TPD

- After-sales Service: Spares, Products, Online, Upgradation, Technical Audit

- Advantage: Flexible Feedstock, Energy Saving, High yield, Eco friendly

- Used for: Diesel Engines, Boilers, Generators, Furnaces

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

Tinytech Palm Kernel Oil Refinery Plant is specially designed and built for processing the Palm Kernel Oil. As you know, palm kernel oil is also referred to as PKO. This oil is obtained from the kernel seeds of the oil palm fruit. The process of extracting the palm kernel oil is through mechanical pressing. The output of seed extraction is the.

Palm oil - Wikipedia

- Usage: Palm Oil

- Production Capacity: 100% Palm crushing equipment

- Model Number: Qie

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw material: Palm, Palm Kernel

- Name: Palm crushing equipment

- Application: Palm oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Advantage: energy saving/high oil yield

- Flowchat: cold press/hot press/prepress

Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. [1] The oil is used in food manufacturing, in beauty products, and as biofuel. Palm oil accounted for about 36% of global oils produced from oil crops in 2014. [2] Palm oils are easier to stabilize and maintain quality of flavor and.

The Model 6yl-130 palm kernel oil press machine is a reliable and high-capacity machine that is ideal for small farms of 3-15 hectares. It can process supplied materials from outside for individual household or pre-pressing in submerging oil workshops. This machine is favored by large and medium-sized oil extrusion workshops due to its.

Physicochemical Properties of Palm Kernel Oil - Semantic Scholar

- Usage: Palm oil processing machine

- Production Capacity: High

- Model Number: Medium-size

- Voltage: Adjustable

- Power(W): Capacity

- Dimension(L*W*H): According the Palm oil processing machine

- Weight: According the Palm oil processing machine

- Oil grade: Grade 1

- Residual oil in meal: ≤ 1%

- Steel type: Carbon steel and 304 steel

- Finished meal moisture: ≤ 10-13% (adjustable)

- Advantage: Energy Saving

- Raw material: Palm, Palm Kernel

- Material: Stainless Steel 304

- Capacity: Large

the pericarp oil used mainly for cooking and the kernel oil used in processed foods ( Osanyinbgemi, 1995). For each hectare of oil palm which is harvested year round the annual production averages 10 tonnes of fruit, which yield 3,000 kg of pericarp oil and 750 kg of seed kernels which in turn yield 250 kg of high quality palm kernel oil as.

The Isomerication and Oxidation of Carotenoid Compounds in the Oil Palm Fruit During Productions of CPO. Indonesia Journal Chemistry. 9(1): 48-53. [MPOB] Malaysian Palm Oil Board. 2004. MPOB Test Method: A Compendium of Test on Palm Oil Products, Palm Kernel Products, fatty Acids, Food Related Products and Others. Prada, F.,

- How to set up a palm kernel oil production plant?

- Setting up a palm kernel oil production plant, many aspects must be taken, including production capacity and requirements of customers, the quality of the final produced palm kernel oil, palm kernel oil processing technology, and more.

- What is palm kernel expeller press machine?

- Palm kernel expeller press machine is designed using the most advanced technology by experienced professionals. These palm kernel expeller press machine make it easy to extract palm kernel oil. We Henan Doing Company have different types palm kernel expeller press machine for people to choose.

- What is palm kernel oil?

- Palm kernel oil is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. It is related to two other edible oils: palm oil, extracted from the fruit pulp of the oil palm, and coconut oil, extracted from the kernel of the coconut.

- Can oil palm trees grow in Kenya?

- It is projected to rise to $88 billion (Sh8.8 trillion) by 2022. The crop, however, is yet to take root in Kenya on a large scale. But studies done by the Kenya Agricultural and Livestock Research Organisation (Kalro) have shown that the oil palm tree can grow along the Equator, particularly in Western Kenya.