semi-automatic palm kernel cooking oil production plant in zambia

- Usage: Palmeed,soyabean,Palm etc.

- Type: cooking oil filter

- Production Capacity: high

- Model Number: vibrative leaf oil filter

- Voltage: 220V, 220V/ OTHER

- Power(W): 7.5kw

- Dimension(L*W*H): as per your capacity

- Weight: 1500kg

- Application: cooking oil filter

- Warranty: One Year

- Material: Carbon Steel

- Application range: oil bleaching section

- Machine color: Greeen

- Capacity: as per your requirement

- Model: YZCL210*5

- Price: Negotiable

- Feature: stainless steel leaf

Some of the steps to start a cooking oil production business in Zambia are as follows: Examine the Market. It is critical to research the demand for cooking oil in various parts of Zambia, as it is heavily influenced by income and population density. The common hot sale cooking oils has soybean oil, sunflower oil, Palm oil, palm oil, palm.

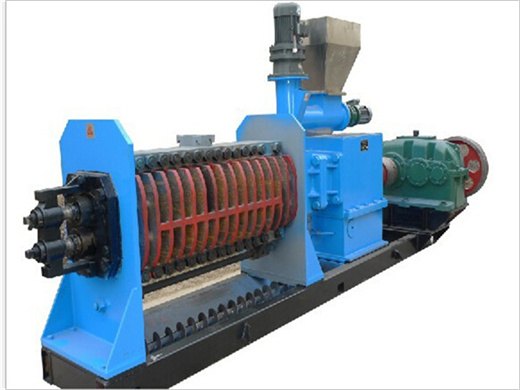

Palm kernel pre-treatment is indispensable to get pure palm kernel oil; more important, the clean palm kernel is a favor to protect oil press and extend its working life. After removing palm kernels shells by palm kernel shelling and separator machine , the shelled palm kernels need the following processing steps.

Palm Kernel Oil Production Line

- Usage: Palm Oil, All kinds of oil s

- Type: Cooking Oil Press Machine

- Production Capacity: 10 TONS /DAY

- Voltage: 30 hp

- Dimension(L*W*H): 2641MM*1016MM*2489MM

- Weight: 5000 KG

- Warranty of core components: 5 years

- Core Components: Motor, Bearing, Gearbox

- Oil type: Palm Oil

- Extraction of Oils: Palm Oil

- MOTOR: 30 HP

- CAPACITY: 10 Tons/Day

- After Warranty Service: Spare parts

- Certification: ISO 9001-2008

Palm Kernel Processing Plant Customized for You. According to different production capacity and customers’ different requirements on the products, our company can make rational choice and combination of palm kernel oil production processes, choose the best technological process, as well as sophisticated equipment manufacture and automatic control system to provide customers with perfect.

A 2-tonnes-per-hour crushing mill was built this year, with plans for a second 2-tonne plant in 2017 and a further 10-tonne plant in the following year, taking crude palm oil production up to 17,000 tonnes a year. The total investment cost is estimated at US$41.5 million, of which Zambeef has spent US$20 million so far.

supplier stainless steel cooking oil machines in zambia

- Usage: Cooking Oil

- Type: Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V

- Dimension(L*W*H): 40*21*58 cm

- Weight: 45 kg, 45 kg

- Core Components: Motor

- model: KN-30W

- capacity: 30kg/hour

- voltage: 220v/50hz

- material: SS304

- Press type: Low temperature press

- Control type: Automatic microscope

- size: 40*21*58 cm

- product name: Palm s oil extract machine/Palm oil making machine

- After Warranty Service: Online support

- Certification: CE ISO

cooking oil production business in zambia. Automatic grade: full automatic Power: 4kw Type: Hydraulic oil press Weight: 6400kg Dimension: 132*54*102cm Product capacity: 8-10 tpd Advantage: High safety level Material: carbon steel After-sales Service: Free spare parts, Video technical support Press Materials: olive,palm kernel,rice bran,hemp.

During palm kernel oil extraction process, there are 3 types palm kernel oil extraciton machine can be choosed, they are: (1)500-800kg/h palm kernel oil expeller machine (2)0.5-2tph palm kernel oil production machine. Small scale palm kernel oil production machine (3)10-1000tpd palm kernel oil processing plant. After palm kernel oil extraction.

Energy Consumption Pattern in Palm Kernel Oil

- Usage: vegetable oils and animal oils

- Type: Batch oil refinery plant

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 15*10*8m3

- Weight: Based on equipment

- Certification: CE ISOBV mini oil refinery

- Capacity: 1-10 tons per day mini oil refinery

- Raw material: Palm oil, Palm oil, fish oil, Palm oil

- Material: Stainess Steel

- Function: Making edible oil

- Advantage: High efficient mini oil refinery

- Spare parts: Cheap and sufficient spare parts available

- Installation: Professional engineers available

- Refining type: Batch mini crude oil refinery

Palm nut cracking and oil expression accounted for 73.4% of the energy consumed in both small mill and medium mills respectively and 85.2% in the large mill. This indicates that these two unit.

The average palm kernel oil extraction rate is about 45.63% and the crusher plant’s energy expenditure decreases as mill capacity increases. Although oil production cost varies due to production conditions, palm kernel oil production cost is the lowest among the major oil crops. The profit margin of palm kernel mill increases with plant capacity.

Palm kernel oil - Wikipedia

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Oil press

- Production Capacity: 20kg/h

- Voltage: 220v

- Dimension(L*W*H): 650*570*1125mm

- Weight: 85kg

- Marketing Type: Ordinary Product

- Warranty of core components: 1 Year

- Core Components: Motor

- Brand: hanchuang

- Model: HC-S01

- With power: 1500kw

- Processing capacity: 20kg/h

- Machine weight: 85kg

- Dimensions: 650*570*1125mm

- Screw diameter: 18mm

- Power supply voltage: 220 (V)

- Oil yield: 42-48 (%)

- After Warranty Service: Online support

- Local Service Location: None

- After-sales Service Provided: Online support

Palm kernel oil. Palm kernel oil is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. [1] It is related to two other edible oils: palm oil, extracted from the fruit pulp of the oil palm, and Palm oil, extracted from the kernel of the Palm. [2]

In Indonesia, the growth in the palm oil production sector is very high, where the annual growth rate was greater than 12 % from 1990 to 2005 [4]. Meanwhile, according to Varqa in Palm Oil.

- What is zampalm ? Zambia’s first palm plantation?

- LUSAKA, ZAMBIA ? Zampalm in Mpika is Zambia’s first ever palm plantation. The plantation boasts 2,800 hectares of palm plants, which when harvested will produce crude palm oil that is the basic ingredient in most vegetable oils on the market in Zambia.

- How to set up a palm kernel oil production plant?

- Setting up a palm kernel oil production plant, many aspects must be taken, including production capacity and requirements of customers, the quality of the final produced palm kernel oil, palm kernel oil processing technology, and more.

- Why is Malaysia the world’s largest producer of palm kernel oil?

- The efforts of the crushers are not in vain. Together they have contributed significantly towards the earning of foreign exchange for the country and making Malaysia the world’s largest producer and exporter of palm kernel oil and expellers/ cakes. The kernel crushers use different processes and machineries in the extraction of oil.

- Is Zambia a good place to grow palm oil?

- While Zambia is not a traditional growing region for palm oil, lower yields are expected to be outweighed by the competitive advantage of being closer to consumers in the region given that the cost of importing edible oil from the Far East can account for around a third of its retail price.