screw sunflower seed oil extraction plant for eu in uganda

- Usage: Sunflower oil

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 1000 KG

- Warranty: 1 Year, 12 Months Sunflower oil making machine

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Raw material: Sunflower ,Sunflower,etc

- Name: Sunflower Cooking Oil Making Machine

- Function: Making Edible Oil

- Application: Oil Production Line

- Advantage: Energy Saving

- Product name: Oli Press Machine

- Color: Clients' Requirements Sunflower oil making machine

- Material: Iron Sunflower oil making machine

- Item: Edible Oil Press Sunflower oil making machine

Implementation of 10TPD Sunflower Oil Pressing Line Project in Uganda. Main Equipment: Seeds Pretreatment Equipment, Screw Oil Press Machine, Edible Oil Refinery Plant. This Vegetable Oil Production Line was established in Uganda in 2016. Now, this project has been running for four years, and the edi ble oils it produced are sold very well in.

Uganda has a variety of oil seeds including sunflower, cottonseed, groundnuts, sesame seed and soybean which can be used in operating an oil seed extraction plant, Dorothy Nakaweesi writes.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Sunflower embryo oil mill

- Production Capacity: 100%

- Model Number: Qie

- Voltage: 380V,440V

- Power(W): according to capacity

- Dimension(L*W*H): 1360*950*1170mm

- Weight: according to capacity

- Certification: CE,ISO9001

- Capacity: 1-1000TPD

- Application: Sunflower embryo oil mill

- Function: extract oil from seed

- Operation mode: Electricity drive

- Machine Name: Sunflower embryo oil mill

- Processing type: Solvent extraction

- Residual oil in meal: ≤ 1%

- Solvent consumption: ≤ 3Kg/T

- Steam consumption: ≤ 3kg/t

- Power consumption: ≤ 15KWh/T

The seeds are screw-pressed until the maximum oil is expressed, and subsequently, the seedcake is subjected to solvent extraction to obtain the residual oil [2, 10, 11]. Comparatively, mechanical.

The seed is mechanically pressed (pre-pressed) to extract approximately half to three quarters of the available oil so that the solvent extraction can be run more efficiently. This is typical for seeds containing more than 20% oil. The solvent extraction process uses hexane or other solvents to wash the sunflower oil from the prepared flakes.

Sunflower Oil Machinery for Sale with Low Pirce and High Quality

- Usage: canola oil extract machinery, Canola seed

- Type: grape seed oil extraction machine

- Production Capacity: 30-2000TPD canola oil extract machinery

- Model Number: Jinxin canola oil extract machinery

- Voltage: 380v or according to the local voltage

- Power(W): According to the capacity of canola oil extract machinery

- Dimension(L*W*H): 1610x615x1260mm of canola oil extract machinery

- Weight: 1050 KG of canola oil extract machinery

- Certification: ISO9001 canola oil extract machinery, ISO

- Name: Canola oil extract machinery

- Automatic grade: Full automatic

- Oil grade: 1st, 2nd,3rd

- Capacity: 30-2000TPD

- After sale service: Engineer abroad service

- Port: Qingdao

Mimi Oil Mill Plant Setup Small(10TPD) Sunflower Oil Production Line in Uganda. Mini Oil Mill Plant: a cleaning sieve, cooking machine, integrated oil press, and screw elevator. Compared to large-scale automated oil mills, it requires less space and investment, while still encompassing full functionality of an oil mill.

1850 MM. Hongde 1500. 45 150 Tonnes per 24 Hours. 3-Phase 170 H.P. 5500 MM. 1380 MM. 1980 MM. Are you looking for the most suitable and cost effective sunflower seed screw oil press or sunflower oil mill plant to start your sunflower seed oil manufacturing business, then you are in the right place. Hongde is the best and reliable manufacturer.

Sunflower Seed Preparation and Oil Extraction

- Usage: Sunflower Oil

- Production Capacity: 250-300KG/H

- Model Number: DYZ-300

- Voltage: 380V

- Power(W): 3KW

- Dimension(L*W*H): 2000x1200x2500mm

- Weight: 2200kg

- Certification: ISO CE SGS

- automatic oil press machine: Sunflower kernel expeller price

- Material: 316 Stainless Steel

- Barrel Dia: 40cm

- Cake oil rate: 3%

- Pressure: 35-50mpa

- Multi-purpose: yes

- Advantage: Energy Saving

- Color: Clients' requirements

- Raw material: Sunflower Seed

- Movable: Yes

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

The positive impact of high temperatures has been observed in the pressing of sunflower seeds, where an oil extraction efficiency of 66% was obtained at 80°C, whereas 70% was obtained at 120°C.

Development and Performance Evaluation of an Optimized Screw

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 6-800kg/h

- Voltage: 220V/110V

- Dimension(L*W*H): 430*150*220mm

- Weight: 7.7 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Product name: Automatic Flaxseed Sunflower Oil Maker

- Press type: screw type

- Keyword: New Home Use Mini Sunflower Oil Press Machine

- Function: double screw press type

- Quality: High-Quality

- Color: Sliver

- Model: MX-B03

- Material: Stainess Steel

- Package: Carton

- Oil rate: Press Cpress Cake Residual: 6%

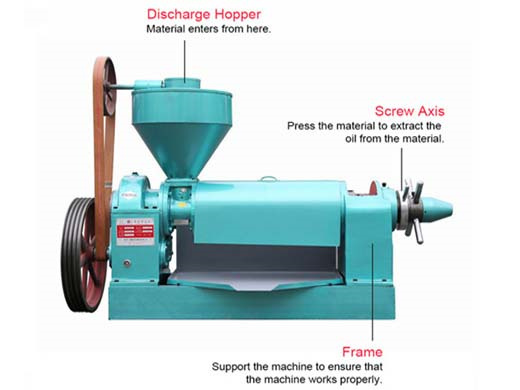

Screw oil expeller is a mechanical device which can generate pressure from rotation of feed to expeller screw manually or automatically. Screw press method for oil extraction is a mechanical method for extracting oil from raw materials. Extracted oil from screw pressing are used either as a food product or as an industrial product.

The screw configuration and the operating conditions had an important influence on the oil extraction yield, the energy input and the quality of oil extracted during the extrusion of sunflower seeds. Higher oil extraction yield and specific mechanical energy were reached as the reversed screw elements were moved with increased spacing between.