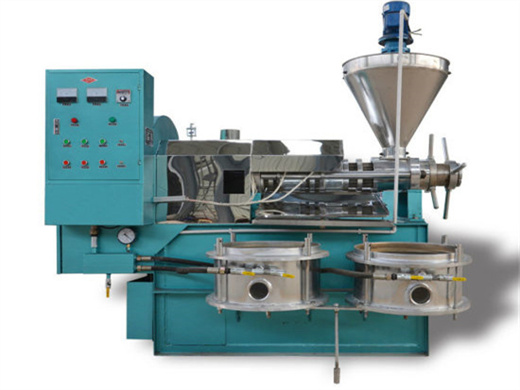

roasted peanut oil extraction machine in togo

- Usage: Peanut Oil

- Type: Peanut kernel oil expeller press machine, Continuous

- Production Capacity: 1T/H & 2T/H

- Model Number: JL061

- Voltage: 380V/410V 3 phase

- Power(W): 30KW

- Dimension(L*W*H): 26000*2000*1500

- Weight: 15tons

- Certification: CE and ISO

- Supplier type: Manufacturer

- Function: make Peanut kernel oil

- Texture: Mild steel and SS

- Raw material: Peanut

- Handling capacity: 1t/h,2t/h,5t/h,10t/h,15t/h,2ot/h

- Warranty: 1 year

- Production cycle: 40days

- Installation period: 60 days

- Shipping terms: FOB Qingdao or Tianjin

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

A study carried out in 2019 by Suri et al. examined how peanut oil quality characteristics were affected by a combination of dry air roasting and mechanical extraction using screw pressing []. The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature.

Peanut Oil Processing Technology

- Usage: Peanut Oil, Cooking Oil

- Type: oil refinery plant

- Production Capacity: 20-2000TPD

- Voltage: 380V,440V

- Dimension(L*W*H): according to capacity

- Weight: 8t

- Certification: CE,ISO

- Use: Edible oil refining

- Skype: mirand.lee

- Application area: Peanut Oil etc

- payment term: T/T 40% in advance ,balance paid

- Delivery time: 25-60 days

- shippment term: FOB or CIF

- package term: : in container or according to customer

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

1. Introduction Oilseeds are important sources for extracting vegetable oils in the food industry. Oils can be prepared by mechanical expression and/or solvent extraction and used for cooking or as food ingredients. According to the statistical data of United States Department of Agriculture (2021), among major vegetable oils, palm, soybean, rapeseed, sunflower seed, palm kernel, peanut.

Peanut proteins: Extraction, modifications, and applications: A comprehensive review

- Usage: Peanut Oil

- Type:

- Production Capacity: 200~2000T/D(daily processing capacity)

- Model Number: POM

- Voltage: 380

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Certification: ISO9001

- Name: high quantity Peanut oil refinery plant oil press machine

- Expanding,Extraction,Refinery:

- Note: 2 years spare parts for free

- Oil pretreatment 1: cleaning section

- Oil pretreatment 2: Breaking section

- Oil pretreatment 3: Embryo pressing section

Abstract. As naturally sourced proteins, peanut proteins have garnered significant attention from the food industry, owing to their numerous advantages, such as easy extraction, non-pungency, and high bioavailability. Furthermore, peanut proteins are highly digestible in the gastrointestinal tract and boast a high net protein utilization rate.

To evaluate the effects of the roasting process on the extraction yield and oil quality, peanut seeds were roasted at different temperatures (130?220 °C) for 20 min prior to the aqueous extraction of both oil and protein hydrolysates with Alcalase 2.4 L. Roasting temperatures did not significantly affect the yields of free oil, whereas the temperature of 220 °C led to a reduced recovery of.

Effects of Roasting Temperatures on Peanut Oil and Protein Yield Extracted via Aqueous Enzymatic Extraction and Stability of the Oil Body Emulsion

- Usage: Peanut , etc

- Production Capacity: 5TPD

- Voltage: 220V/110V

- Dimension(L*W*H): 56*26.5*33cm

- Weight: 13 KG

- Core Components: Motor, Gear

- Oil type: Peanut Oil

- Product name: stainless steel home Peanut oil machine sri lanka for sale

- Function: oil etraction, oil mill

- Used for: Peanut , Peanut

- Working ability: 40-600kg/H

- Material: 304 food grade stainless steel

- Squeezing type: hot/cold press

- Machine color: Stainless steel

- Keep working: 12 hours

- Oil extraction: 90% oil yield

- Size: mini, small size

- After Warranty Service: Video technical support, Online support, Spare parts

- Certification: CE ISO

Oil body emulsions (OBEs) affect the final oil yield as an intermediate in the concurrent peanut oil and protein extraction process using an aqueous enzyme extraction (AEE) method. Roasting temperature promotes peanut cell structure breakdown, affecting OBE composition and stability and improving peanut oil and protein extraction rates. Therefore, this study aimed to investigate the effects of.

Peanut oil is favored by consumers due to its rich nutritional value and unique flavor. This study used headspace solid-phase microextraction (HS-SPME) combined with gas chromatography (GC) and gas chromatography?mass spectrometry (GC-MS) to examine the differences in the peanut oil aroma on the basis of variety, roasting temperatures, and pressing components. The results revealed that the.

Impact of different extraction processes on aflatoxin contamination in peanut oil | Journal of Food Science and Technology - Springer

- Core Components: Motor, Drum

- Voltage: 380V/50HZ

- Power: 0.75kw

- Dimension(L*W*H): 1500*1200*900mm

- Weight: 2100kg

- Application fields: Dairy products factory, Cooking oil factory, Vegetable processing plant, Snack food factory

- Raw material: Nuts, Peanut

- Product name: Hot Air Drying Machine

- Usage: Reduce Material's Moisture

- Material: Steel plate painting

- Function: Food Vegetable Fruit Dehydrator

- Advantage: Low Consumption High Efficiency

- Heating source: Steam

- After Warranty Service: Video technical support, Online support

- Certification: CE

Aflatoxins (AFs) are genotoxic carcinogens and are a growing concern in peanuts and peanut products. This study aims to impact of different extraction processes on the transition of AFs from peanuts to oils. Peanuts were collected from nine different factories in Osmaniye, Turkey, during the period of November 2017?May 2018. While no aflatoxin G1 (AFG1) and aflatoxin G2 (AFG2) were detected.

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- How to extract oil from peanuts?

- Oil production requires some type of press with which to extract the oil form the groundnuts and filtering equipment. Practical Action has developed a simple manual screw press that would be suitable for extracting oil from peanuts, as well as many other agricultural crops.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.