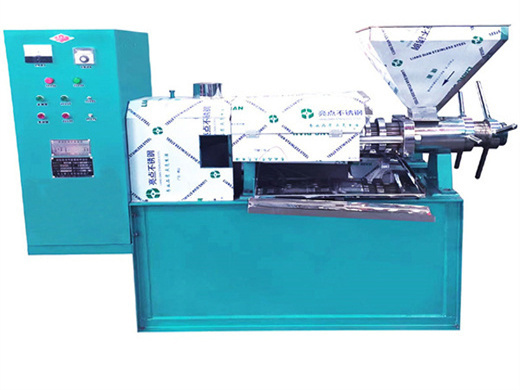

pure soybean oil extract cold pressed extracti in uganda

- Usage: Mustard Oil, Soybean Oil

- Production Capacity: 160kg/h

- Voltage: 380v

- Dimension(L*W*H): 2000*1600*2700mm

- Weight: 1500 KG

- Core Components: Motor, Pump, Gear, Engine, Gearbox, squeezer

- Oil type: Soybean Oil

- guarantee period: one yes

- Function: Press Oil Seeds

- Advantage: High Oil Press Yield Rate

- Feature: Efficient

- Shipping method: Sea

- Quality: High Level

- Package: Wooden Box

- Suitable for: Small Oil Workshop

- Model: screw oil press machine

Since 1950s, manufacturers also started using refining process for groundnut, sesame, coconut, etc. Refined oil extraction has higher oil yield. For example, in cold pressed method we need 2.5kg of groundnuts to make 1 litre of groundnut oil. The refined process will extract 1 litre of oil from 2.2 kg of groundnuts.

The extraction of soybean oil and free fatty acids was evaluated using ethanol with different hydration levels (from anhydrous to 5.98 wt%) by Toda et al. [29]. It was found that the increase in water content suppresses soybean oil extraction and increases the free fatty acids content.

Cold press in oil extraction. A review - ResearchGate

- Usage: Soybean Oil

- Type: whole Soybean oil extraction equipment

- Production Capacity: 100%

- Model Number: 1st series Doing Soybean oil extraction equipment

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Soybean Seed

- Product: to make crude Soybean oil or refined Soybean oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000T Soybean oil extraction equipment

- Oil content in Soybean: about 40%

- Oil residues: less than 1%

- Function: getting Soybean oil

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

In the cold-pressing process, oil is extracted by only exerting pressure on the seeds at a low temperature exclusive of chemicals or extreme heat (Cakaloglu et al. 2018). The samples of each meal.

for oil extraction from oilseeds with oil content below 20% [4]. Pressure is used in the separation of the mentioned phase separation. And depending on whether or not the temperature is applied, it is called hot or cold press extraction [5]. Cold press machine has one inlet that seeds were feed and two exits that obtained oil

Extraction of oil from oilseeds by cold pressing: A review

- Usage: pretreatment,extraction,refining, vegetable seeds oil mill for extraction machine

- Production Capacity: according the capacity

- Model Number: 1-200T/D

- Voltage: 380V or 440 V

- Power(W): according the capacity

- Dimension(L*W*H): according the capacity

- Weight: according the capacity

- Certification: BV and CE

- solvent:

- residual oil in cake: 1%

- extractor type: rotocel extractor

- capacity: 20-500TPD

- Equipment material: Stainless steel or carbon steel

- Raw material: Soybean Seed

- Extractor system: Toasting system

- Use:

- Solvent:

Abstract. Cold press oil extraction method is more energy-efficient and environment friendly than other oil extraction methods. When edible oil is extracted and processed using the cold pressing.

Fig.1. Novel Oil Extraction Technologies (Wiley Online Library.com) Cold press machine has one inlet that seeds were feed and two exits that obtained oil and a non-oiled cake was exit. In the cold pressing method, the pre-treatment and process parameters applied to the raw material have a significant impact on oil yield.

The Effects of Oil Extraction Methods on Recovery Yield and

- Usage: Soybean Oil

- Production Capacity: 5-500 TPD

- Model Number: X1826

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

The sediments from cold-pressed RPC had a significantly higher oil content as compared with the hot-pressed sediments. This could be due to a higher initial oil content in the cold-pressed RPC or co-sedimentation of oil with proteins, as oleosins are efficient emulsifiers. The high oil content in the cold-pressed RPC was a surprise to the authors.

In modern press extraction, oilseeds or nuts are cleaned, and the shells or hulls removed; the kernels or meats are ground to a coarse meal that is pressed with or without preliminary heating. Cold-pressed oil, also called cold-drawn, or virgin, oil, is purer and has a better flavour than oil expressed with the aid of heat. After pressing the.

Soybean oil extraction with ethanol from multiple-batch

- Usage: Soybean Oil

- Type: Soybean oil production line

- Production Capacity: 98%

- Model Number: PO68

- Voltage: 380V/50HZ

- Power(W): depend on the capacity of Soybean oil extraction machine in kenya

- Dimension(L*W*H): depend on the capacity of Soybean oil extraction machine in kenya

- Weight: depend on the capacity of Soybean oil extraction machine in kenya

- Certification: CE ISO9001

- Material: Stainless Steel And Carbon Steel

- Raw material: Soybean Seed

- Soybean fruit reception system: Sterilizer

- Distillation range: 68-75℃

- Indine value: 44-46gl/100g

- Transparency: 500c

- Acid value: less than 1.0mg koh/g

- Crude oil moisture and volatile: Less than 0.30%

- Spare parts: Supply

Despite the fact that soybean oil extraction with hexane is more efficient, in terms of a more concentrated miscella, the outcomes obtained in this study revealed that is possible to exhaust the raw material with ethanol, and that a high oil recovery value can be reached when a S/F = 3/1 is employed. Although the extract obtained with ethanol.

Cold-Pressed Extraction. Cold-pressed extraction, in contrast, is a mechanical extraction method primarily employed for obtaining oils from plant sources such as seeds, nuts, and fruits. The key feature of this technique is that it operates at low temperatures, typically below 120°F (49°C), to avoid the application of heat.

- Are cold pressed soybean oils solvent-extracted?

- Commercial soybean oils are commonly solvent-extracted and refined due to their high phosphatides contents. Hence, few studies exist on characterization of cold pressed soybean oils in the literature.

- Does solvent extraction reduce -tocopherol in soybean oil?

- Kania et al. (2004) reported that solvent extraction of soybean oil yielded higher total tocopherols content (1448 mg/kg) than cold pressing (1358 mg/kg), and the refining process led to the loss of α-tocopherol by 37%, β-tocopherol by 56%, γ-tocopherol by 17%, and δ-tocopherol by 34% in solvent-extracted soybean oil.

- How is soybean oil extracted?

- Soybeans are crushed in a roller mill and then the oil is extracted using a solvent, typically hexane. Hexane-based processing can lead to the production of greenhouse gases and concerns regarding safety due to the flammable nature of the solvent (Rosenthal, Pyle, & Niranjan, 1996).

- What is aqueous extract from whole soybeans?

- Within industry, aqueous extract from whole soybeans is commonly used for making consumer products containing both soy protein and soybean oil, and this has been the focus of this review. Key extraction process parameters are presented and challenges of each extraction step are given for the whole soybean extraction process.