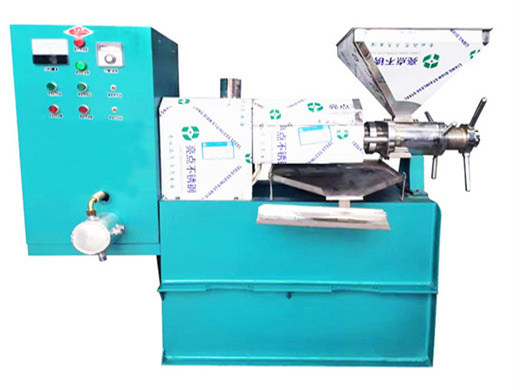

popular coconut kernel oil processing machine in bangladesh

- Usage: Coconut Oil

- Type: Cold & Hot Pressing Machine, Coconut oil squeezer

- Production Capacity: 250-400 kg/h

- Model Number: 6YL-130

- Voltage: According to customer demand

- Power(W): 21 KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

- Certification: ISO9001-2008

- Color: White, green

- Production Material: Carbon steel, stainless steel

- Raw material: Coconut

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical extruding

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Hongde 1500. 45 150 Tonnes per 24 Hours. 3-Phase 170 H.P. 5500 MM. 1380 MM. 1980 MM. Are you looking for the most suitable and cost effective Coconut Oil Extraction Machine or Coconut Oil Extraction Plant to start your own Coconut Oil Manufacturing Business, then you are in the right place. Hongde is the best and reliable manufacturer.

Hongde helps its customers establish an efficient Virgin Coconut Oil (VCO) Extraction Plant to start their business. All our Oil Mill Machinery & Equipment are well known for their quality, long-lasting and durable. We undertake turnkey project solutions for the complete VCO Extraction Plant and also guide you step-by-step to make your oil.

Coconut Food Production | Coconut Handbook

- Usage: Coconut Oil, All kinds of oil seeds

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 380V

- Dimension(L*W*H): 2400*1600*2600mm

- Weight: 1200 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- Function: Making Edible Oil

- Keyword: Coconut oil making machine

- Feature: High Efficiency Low Cost

- Material: Stainess Steel

- Capacity: 3.4t/24h

- Quality: High Level

- Method to press: Screw Squeezed Press

- After-sales Service: Online Service

- Character: High Effiency

- MOQ: 1 Set

Coconut oil is rich in saturated fatty acids and low in unsaturated fatty acids. The different fatty acids present in coconut can range from C6-C18 carbon atom chains. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used.

Virgin coconut oil is a useful substance in our daily life. It contains a high percentage of lauric acid which has many health benefits. The current industry has developed several methods to extract the oil out from the coconut fruit. This review paper aims to highlight several common extraction processes used in modern industries that includes cold extraction, hot extraction, low-pressure.

COCONUT - Food and Agriculture Organization

- Usage: Coconut oil extrction machine

- Type: Coconut oil extrction machine

- Production Capacity: 100%Coconut oil extrction machine

- Model Number: Coconut oil extrction machine

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Certification: CE ISO BV SGS

- Item: Coconut oil extrction machine

- Raw material: Coconut

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

Though coconut can be processed into many products, the next part focuses on the processing of coconut oil, highlighting the dry-process of coconut oil extraction and two improved coconut oil extraction technologies which have proven to be adaptable at the village level, namely: a) The Hot-Oil Immersion Drying Technology; and b) The Ram Press.

Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business: Boiler. Copra Cutter. Copra Dryer. Cooker / Kettle. Copra Oil Expeller Machines. Crude coconut oil storage tanks. Oil Filter Press Machines. Bucket Elevator.

Processing technologies for virgin coconut oil and coconut

- Usage: Solid Liquid Separation

- Type: Pressing Machine

- Production Capacity: High Efficiency

- Voltage: Customized

- Dimension(L*W*H): 5690*1840*1630(mm)

- Weight: 11750 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Bearing

- Oil type: Coconut Oil

- Material: Carbon steel

- Filter plate material: PP

- Plate Shifter: Automatic

- After Warranty Service: Field maintenance and repair service

- Local Service Location: Viet Nam

- Certification: ISO9001, CE

In wet processing, the coconut milk is extracted from the fresh kernel which is then fermented naturally (at 35-40°C for 16-24 h) to obtain VCO from coconut curd by phase separation. The meal is.

Power Supply. 240 V / 1 ph / 50 Hz. Power Rating. 1.00 hp. Machine Weight. 200 kg. Machine Size ( L X W X H ) 0.60 X 0.50 X 1.10 m. Coconut paring machine COM30 scalps off the soft and brownish skin, or testa, of deshelled coconut kernel ( in pieces ) via a rotating trimming cutter.

CoCoMaN Coconut Machines

- Usage: crude Coconut oil refining mill

- Production Capacity: 2T~10TPD

- Model Number: Q-0615

- Voltage: 220V/380V

- Power(W): 20KWh/T

- Dimension(L*W*H): 30*15*10m

- Weight: depend on the capacity

- Certification: CE, BV, ISO9001

- Item: crude Coconut oil refining mill

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- After sale service: Yes

- Raw material: Coconut

- Operating pressure: normal/negative pressure

- Origin: China

A coconut paring machine is used to scalp off the testa or the brownish skin of coconut kernel to obtain white coconut kernel. A coconut grinding machine is used to grind the white coconut kernel pieces into coconut flakes. A coconut milk extracting machine is used to squeeze the coconut flakes to obtain coconut milk.

C oconut oil is produced by crushing copra, the dried kernel, which contains about 60-65% of the oil. The oil has the natural sweet taste of coconut and contains 92% of saturated fatty acids(in.

- What are the different types of coconut oil processing methods?

- Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process.

- How a coconut kernel is converted into copra?

- Coconut kernel is converted into copra before it is expelled and refined for oil production. This is done by first drying the kernel under the sun in an oil mill. To extract coconut oil for extensive food and industrial purposes, dry processing is used.

- What are the components of coconut oil making machine?

- The main components includes heat conduction oil furnace, steam generator, deodorizing pot, decoloring pot, refining pot and leaf filter. It is suitable for 1-5TPD Refinery Plant. Hongde Machinery offers high quality coconut oil making machine and complete processing plant, capacity ranging from 1 TPD to 20 TPD.

- What is coconut oil refining machine?

- It is a semi-automatic oil production machine set which connects each coconut processing equipment including sieving machine , cooke r, oil press and filter, and conveyors. It is an efficient assembly unit to extract coconut oil from copra. This is a small complete oil refining unit for edible oil production, based on batch type refining process.