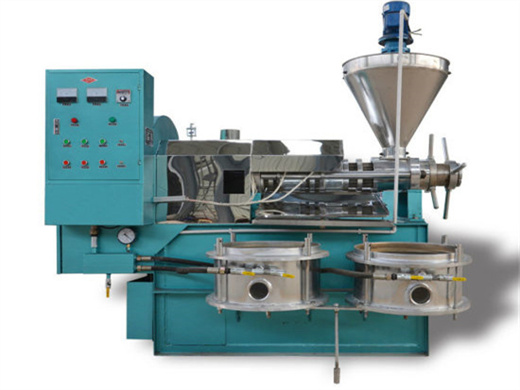

peanut s oil extraction machine approved in bangladesh

- Usage: Oil Press Extraction

- Production Capacity: 100%

- Model Number: Peanut oil pressing machine

- Voltage: 220V/380V

- Power(W): 15kw

- Dimension(L*W*H): 1700*1300*1600

- Weight: 1200kg

- Certification: ISO9001

- Product name: Oil Press Extraction

- capacity: 250-400kg/h

- size: 2200x1600x2150mm

- power: 15w

- staff requirement: 2-3 persons

- space requiremen t: 40-60square meter

- Gear ratio: 15/38x19/48=1

- Vacuum pump: Y100L1-4-2.2KW

- Heater: 3.8KW

- Authentication: ISO9001

Hongde SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana, Sudan, Mali, Burkina Faso.

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60?70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: make red Peanut oil, make crude red Peanut oil

- Type: Peanut oil processing machine, Mechanical presser

- Production Capacity: 10TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 260 KG

- Core Components: Gearbox

- Oil type: Peanut Oil

- Processing material: FFB

- Final product: crude Peanut oil

- Processing capacity: 300-500kg/h

- Oil residual rate: 7%-8%

- Application: Usage for small scale Peanut oil mill plant

- Advantage: High Oil Yield

- Advantage 1: Factory directly sale

- Color: Optional

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Groundnut Oil Extractor - Peanuts Processing Machine

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine, vegetable oil extraction machines/Peanut oil

- Production Capacity: 10-5000T/D

- Model Number: DT-10030

- Voltage: 220V/380V/415V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Certification: ISO9001

- Raw material: Peanut

- Function: Vegetable Oil

- Suitable for: Peanut, Cotton, Peanut,etc

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

Solvent Extraction Plant , oil seed processing plant. Having experience of years, we Kumar Metal Industries Pvt. Ltd. is an ISO 9001-2008 approved company with CE and ATEX certifications providing Turnkey Solution of solvent extraction plant,oil mill plant,edible oil refinery plant,oil seed processing plant etc, Our corporate headquarters are located in Mumbai.

BEST Price Peanut Oil Extraction Machine for High Efficient

- Usage: Peanut Oil

- Production Capacity: 5-500 TPD

- Model Number: Z1916

- Voltage: 440V

- Weight: 500TONS

- Certification: ISO,CE

- After-sales Service Provided: Engineers available to service machinery overseas

The YZS series peanut oil extraction machine is well designed to meet the all the production capacity for best oil output. () It is mainly composed of feeder, pressing cage, gear box, screw axis and more. The feeding system includes feeder, feeder flange, etc. The pressing cage includes upper and lower pressing cages, roll bar, pressing rings.

To optimize this process, the effects of ultrasonic time (0?70 min), cellulase enzyme concentration (0?2%) and pH (4?5.5) are investigated on peanut oil extraction yield (EY) as well as the.

Peanut / Groundnut Oil Extraction Machine Manufacturers and

- Usage: Wheat and Peanut flour mill

- Type: Wheat and Peanut flour mill

- Production Capacity: 100%

- Voltage: 380V/50Hz/3Phase

- Power(W): 7.5kw

- Dimension(L*W*H): 37*7.5*18.5-87*12*30

- Weight: 10Ton-100Ton

- Certification: SGS.ISO.BV.CE

- Item: Commercial Flour Mill For Sale

- Material: Stainless Steel 304

- Function: Wheat and Peanut flour mill

- Advantage 1: Energy Saving

- Advantage 2: Lower power consumption

- Advantage 3: Zero Pollution

- Feature: High output

- Performance: Excellent

- Processing type: Cleaning-milling-packing

Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs and improve oil production.

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What are the best oil extraction machines in India?

- In India’s best oil extraction machines, a big deceleration box is used for more stable cold press oil extraction. The machine has a positive pressure oil filtration system that removes impurities from crude oil particles. 1. Savaliya Industries SL-801 Cold Press Oil Maker Machine