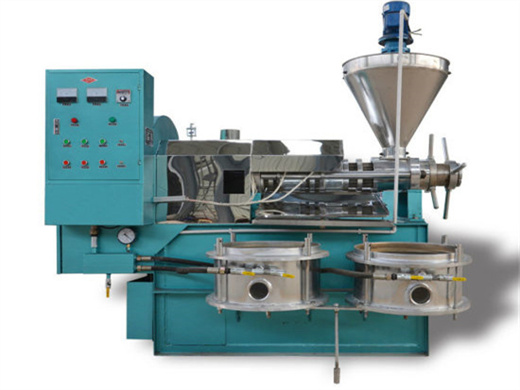

peanut oil solvent extraction machine extractor in lesotho

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine

Automatic Grade: Semi-Automatic - Production Capacity: 100%

- Voltage: 220V

Power(W): 5.5kw - Dimension(L*W*H): 46*32*36cm

- Weight: 130kg

Certification: ISO9001 - Product name: Vertical manual screw press machine

Application: Screw Oil Expeller - Item: Vertical Oil Press

- Advantage: Energy Saving

Character: Screw Oil Pressing Machines - Warranty: One Year

- Function: Hot Press

Feature: Multifunction - Product: Oil Reach

- Section: Pre Pressing Section

Groundnut Oil Mill Plant. Hongde SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana.

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

Peanut Oil Processing Technology

- Usage: Peanut fiber machine

- Type: Peanut fiber machine

- Production Capacity: 1-2000TPH

- Model Number: DL-ZYJ06

- Voltage: 220V/380V

- Power(W): 18.5KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Certification: CE,BV, ISO

- Equipment name: Peanut fiber machine

- warranty: 1 year

- material available: Peanut fiber machine

- texture: stainless steel, carbon steel, alloy steel

- projects done: 1-2000TPD complete oil lines

- markets: America, Europe, Africa, Asia, Australia

- delivery: within 1 month after the payment

- services: engineering, producing ,installation, construction

- Advantage: Energy saving, environment friendly

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60?70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the.

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

Peanut/groundnut oil extraction process - LinkedIn

- Usage: Peanut Oil, Peanut EDIBLE OIL

- Type: Oil Extraction Machine

- Production Capacity: 100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 800*400*800mm

- Weight: 2100kg

- Core Components: Other

- Oil type: Peanut Oil

- Raw material: Peanut, mustard,Peanut,flaxseed,hemp,Peanut oil

- Name: Peanut Oil Usage 6YL-68 oil extractor machine hemp oil screw press

- Material: Iron

- Application: Edible oil production

- Function: Making Edible Oil

- Advantage: Energy Saving

- Product name: hemp seed oil press

- key words: Peanut Oil Usage 6YL-68 oil extractor machine

- After Warranty Service: Video technical support

- Quality: Top Level

Major equipments of peanut/groundnut oil extraction machine: extractor, D.T.D.C desolventizer-toaster, stripping tower, dryer, condenser, absorber

Rotocel extractor is also used for extracting capsicum red pigment. Advantages: (1) Simple structure, easy operation, and maintenance. (2) Adopt stainless steel stationary grid, with an additional horizontal grid to prevent backflow of thick miscella into the material cells. The grid gap has a self-cleaning effect and is free of clogging.

Green solvents and technologies for oil extraction from

- Usage: vegetable oil plants

- Type: Cold & Hot Pressing Machine, Screw press oil

- Production Capacity: 200~600kg/h

- Model Number: 6YL-160RL 0608

- Voltage: adjustable

- Power(W): 18.5KW

- Dimension(L*W*H): 2500*1600*2500mm

- Weight: 1800kg

- Certification: ISO9001

- Appearance: vertical

- Plant: 30~50 square meters

- Business type: Manufacturer

- Accepted Delivery Terms: FOB, CFR, CIF, EXW

- Guarantee:

- Packing: Wooden package

- Suitable objects: Peanut etc.

- Residual oil in cakes: 5~6%

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n -hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a solvent has lead to several.

The three major steps involved in solvent extraction are oilseed cleaning and conditioning, oil extraction, and separation of the miscella. Crude oil and meal quality depend mostly on type of solvent used, reaction temperature, and type of pretreatment given to the oilseed [ 25, 26 ].

Groundnut Oil Extraction Process - Peanut M

- Usage: Peanut germ oil extracting machine

- Type: Cold & Hot Pressing Machine

Production Capacity: 98% - Voltage: 380V/50HZ

Power(W): 2.1KW - Dimension(L*W*H): 1700*1100*1600mm

- Weight: 20000KG

Certification: CE ISO - Raw material: Peanut

- Advantage: Energy Saving

- Use for: Peanut germ oil extracting machine

Application range: Kinds Seeds - Feature: Eco-Friendly

Color: Blue - Section: Oil Refinery Machine Section

- Quality: Super High

The extraction of oil can be divided into one pressing and prepressing. A press called full press, press process requirements will peanut oil press material as much as possible to squeeze the oil in cake 3% ~ 5%. The pre press press process requires only about 70% of the oil press material is pressed cake of residual oil in 15% ~ 18%, pre.

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

- What is the workflow of peanut oil solvent extraction plant?

- The workflow of peanut oil solvent extraction plant including extracting, desolventizing, evaporating and stripping, condensing and recovering. First, using organic solvents to extract oil from press peanut cake inside oil extractor, then we can get mixed oil and wet meal.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is solvent extraction of peanut oil?

- The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- Voltage: 380V/50HZ