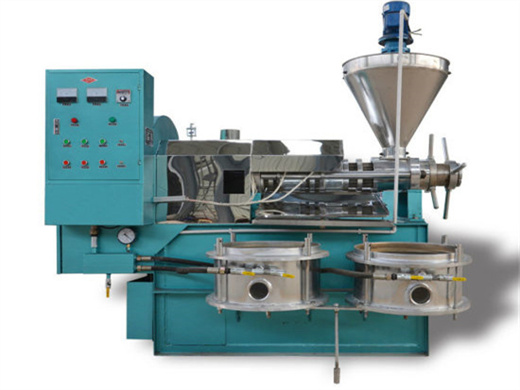

peanut oil processing extractor machine in nepal

- Usage: Oil

- Type: Oil Extraction Machine

- Production Capacity: 1t/day-1t/hour

- Voltage: 220V

- Dimension(L*W*H): 51*50*26 cm

- Weight: 4400 kg

- Core Components: Motor, Other

- Oil type: Peanut Oil

- Model: ML-20ZY

- size: 51*50*26 cm

- capacit: 2000 kg/h

- Feature: Automatic Machine

- Color: Silver

- Function: Making Edible Oil

- Used for: Edible Oil Making

- Advantage: Energy Saving

- Item: Industrial Oil Extractor

- Application: Edible Oil Production

5.5 to 11 kw. Machine Weight. 330Kg-1000 kg. Machine size. 1500*500*1250 mm or higher depending on capacity of machine. Machine Warranty. One year. Please call us for more information in oil machine: 9851181127; 9801028118. Submit your review Cancel reply.

One popular method of extraction is cold press power, employed by machines like the automatic peanut oil press and cold press peanut oil extraction machine. Using advanced oil processing technology, these machines extract the oil from groundnut (another name for peanuts) without the application of heat, preserving the quality of the oil.

How to Choose the Best Oil Press Machine for Home Use- Nepal

- Usage: Peanut Oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 100TPD Peanut oil refining machinery

- Model Number: small scale Peanut oil refining machinery

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales Service Provided: Overseas service center available

- Keywords: small scale Peanut oil refining machinery

- Name: Peanut oil refining machinery

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: oil refining machinery

- oil rate: 20%-98%

Palm Oil Processing Machines come with a processing capacity of 15 tons per hour. The soybean oil extraction machine comes in a capacity of 2 to 4 kg/hr. Whereas, Peanut Oil expeller comes in 4-8 kg per hour. As per the capacity and type of oil machine you are seeking, you can shortlist your favorites and place an order from a genuine supplier. 3.

As shown in Fig. 3.4, during the process the temperature rises from 60 to 90°C, the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C. . However, during the process of the temperature rise, the content of the soluble protein of the residual cake decreases slightly at 60?70°C, and when the temperature exceeds 70°C, the content of the soluble protein of the.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: edible oil

- Type: Peanut oil refining equipment

- Production Capacity: Peanut oil refining equipment

- Model Number: Peanut oil refining equipment

- Voltage: 220V, 380V,or other

- Power(W): depend on the capacity

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- Certification: BV, ISO9001, CE, etc...., BV, ISO9001, CE, etc. for alibaba oil refinery equipment

- Product name: Peanut oil refining equipment

- Color: depend on requirements for oil refinery equipment

- Electric consumption: 28kwh/T oil

- Use: use oil refinery equipment to refine oil

- Capacity: based on requirements for oil refinery equipment

- Steam consumption: 450kg/T oil

- Deodorization loss consumption: ≤0.5%

- Bleaching earth consumption: 5~50Kg/Toil

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Explore the peanut press machine's role in oil yield | Duyvis

- Supply Type: OEM/ODM

- Type: Peanut Oil

- Model Number: SFO-1

- Product name: Cold Pressed Peanut oil Ukraine quality

- Purity: 100 % Pure natural cold pressed or refined

- Appearance: Pale Yellow to Golden yellow

- Function: Health Care Moisturizing Losing weight

- Raw Material: Peanut

- Odor: Characteristic Odor

- Usage: Skin Care Health Care Products cooking oil food

- Extraction Method: Cold Pressed from seed

- Grade: Available in Cosmetics Grade and Food Cooking oil

- Certification: GMP/COA/MSDS

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

The first two steps—cleaning and shelling—happen before the peanuts arrive at the oil mill. Inside the peanut oil extraction plant, roller mills crack the peanut kernels into smaller pieces to increase the surface area for conditioning and pressing. This also removes the peanut skins, which can be blown off with an air separator.

Groundnut Oil Extractor - Peanuts Processing Machine

- Usage: oil press

- Production Capacity: 260-400kg/h

- Voltage: 380v, 50Hz, 3 phase (can be changed for customers)

- Dimension(L*W*H): 2050*1550*1800mm

- Weight: 1500 KG

- Core Components: Motor, PLC

- Oil type: Peanut Oil

- Feature: Vacuum filter

- Diameter of squeezing bolt: 120mm

- Speed of squeezing bolt: 36r/min

- Heater power: 4KW

- Peanut oil yield: 11-16%

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

This mini peanut oil mill plant consists of several major peanut oil processing machine, such as peanut cooker machine, peanut oil press machine and crude peanut oil filter machine. This mini peanut oil mill plant is featured of easy installation, commission and operation. It requires small land space and small investment compared with large.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What are the best oil extraction machines in India?

- In India’s best oil extraction machines, a big deceleration box is used for more stable cold press oil extraction. The machine has a positive pressure oil filtration system that removes impurities from crude oil particles. 1. Savaliya Industries SL-801 Cold Press Oil Maker Machine

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?