peanut oil pressing line for in rwanda

- Usage: Peanut Oil, All kinds of oil seeds

- Type: Oil Press Machine

- Production Capacity: 1 ton/day

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 4.26 *1.55*3.52 ft

- Weight: 0 KG

- Warranty: One Year warranty against manufacturer defect.

- Warranty of core components: Other

- Core Components: Other

- Oil type: Peanut Oil

- complete Warranty Service: Video technical support

- After Warranty Service: Spare parts

- On site Warranty Service: Field maintenance and repair service

- Raw material: Oil Seeds

- Function: Making Edible Oil

- Product name: Oli Press Machine

- Application: Edible Oil Production

- Keyword: Oil Expeller

- Used for: Edible Oil Making

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

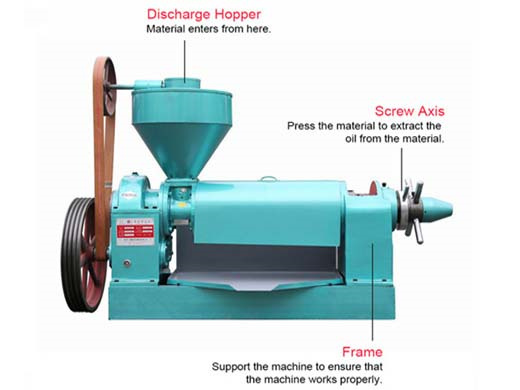

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

Production, Processing, and Food Uses of Peanut Oilseed, Oil, and Protein - List - Major Reference Works - Wiley Online Library

- Usage: Peanut Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 30-80KG/H

- Voltage: 220v/380v/Customer request

- Dimension(L*W*H): 1020*720*798mm

- Weight: 300 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Name: Oil nut seed press machine

- Raw material: Peanut Peanut

- Function: Oil Pressing

- Operation: Automatic Operate

- Advantage: Energy Saving Low Residual

- Oil rate: Meal Residual: 1%

- Capacity: Large

- Material: Stainess Steel

- Processing Types: Screw Pressing

- Keep working: 24 Hours

Peanut oil is considered as a premium edible oil and commands a high price in both US and European markets. In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction.

Peanut Oil Pressing Methods. Generally, the husk content of peanut is 30-35%, and the oil content in peanut kernel is 40-50%. Therefore, the peanut pretreatment processes include cleaning, dehusking and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing.

Bioactive Phytochemicals from Peanut Oil Processing By-products

- Usage: oil seed oil refining machine

- Type: oil seed oil refining machine

- Production Capacity: 1-100T/D

- Model Number: YU20

- Voltage: 380V/440v

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Certification: ISO9001/BV/CE

- Main export countries: Asia,Africa,Latin American,Malaysia...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- refined oil: 1st grade edible oil

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- Refiney type: oil seed oil refining machine

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68?72% of the peanut, while the balance 28?32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Abstract. This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses.

Processing and Food Uses of Peanut Oil and Protein

- Usage: Peanut Oil, Cooking Oil

- Production Capacity: 5TPD-100TPD

- Voltage: 220v/380v

- Dimension(L*W*H): 600*600*1050

- Weight: 550kg-1900kg

- Core Components: Motor

- Advantage: High Oil Yield

- Name: Oil Press Machine

- Product name: Oli Press Machine

- Keyword: Machine Oil Press

- Color: Customer Required

- After Warranty Service: Video technical support, Online support

- Certification: CE/ISO9001

A ton of shelled peanuts increased oil yield to 100?115 gallons and 1100?1200 pounds of cake at 40?50% protein. Data ( Dean and Sanders, 2009) on the oil content of 108 peanut cultivars grown in Tifton, Georgia, indicate a maximum of 47.8% oil and a mean of 44.2% oil.

ABSTRACT. High oleic cultivars are becoming increasing prevalent in the peanut industry due to their increased shelf life compared to conventional cultivars. High oleic peanuts are typically defined as having oleic acid/linoleic acid (O/L) ratios ≥ 9, whereas most traditional varieties have O/L ratios near 1.5-2.0. In practice, this ratio can vary substantially among commercial material.

Physicochemical Characteristics, Functional Properties, and Nutritional Benefits of Peanut Oil: A Review - ResearchGate

- Usage: Peanut OIL, Cooking Oil

- Type: Oil Press Machine

- Production Capacity: 7-800kg/time

- Voltage: 380 V

- Dimension(L*W*H): 800*700*1400mm

- Weight: 500 KG

- Warranty: 2 years

- Core Components: Motor

- Oil type: Peanut OIL

- color: silver

- Heating ring power: 2kw

- Feeding/time: 7-800kg

- KN pressure: 1900 KN

- application: Peanut and so on

- material: stainless steel

- product name: hydralic Peanut oil presser machine

- After-sales Service Provided: Video technical support

of peanut oil by an enzyme-assisted aqueous extraction using protease, cellulase, and α -1,4-galacturonide glycanohydrolase either separately or in combination.

Model: TZ-800. Capacity: 800kg/h. Shelling ratio: 95%. Clean ratio: 98%. Motor: 4kw. Dimension:1520*1060*1660mm. It has proved that the use of dehulled peanuts by a peanut shelling machine to press oil can reduce the absorption of oil by the shell and increase oil production. The use of shelled peanuts can improve the processing capacity of the.

- What is peanut oil production line?

- The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- How peanuts are used in China?

- Among the total peanuts for consumption in China, more than 50% of peanuts are used for oil production, which has become the main pattern of peanut consumption in China. Currently, there are two pressing methods: high-temperature pressing and cold pressing.