peanut oil extraction machine to in indonesia

- Usage: Innovative processing of fructose syrup

- Type: high fructose syrup processing

- Production Capacity: 10-100T/D

- Voltage: Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Core Components: Motor, Pump, PLC

- Capacity: 10-100T/D

- Processing Material: defatted Peanut/Peanut flour

- After Warranty Service: Online support

- Local Service Location: Russia, Thailand, Bangladesh, Kazakhstan, Nigeria, Uzbekistan

- Certification: ISO9001: 2000

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

The crude oil comes out and is filtered through an oil filter. electric oil press The same process is used to squeeze the oil from the seeds. The seeds don’t have to be fried, they can be directly squeezed into oil. oil extraction machine cold press Shelled peanuts yield the same oil as unshelled peanuts. Shelled peanuts are rich in fiber so.

peanut oil processing and basic principle and method of making peanut oil - oil press machine

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine

Voltage: 380V/22V,50Hz/60Hz, three phase - Certification: SGS,CE,ISO

product name: Peanut oil fruit processing equipment - type: Peanut oil equipment

- business scope: FFB to CPO or CPKO

warranty period: 12months - project: turkey project

- certifficction: CE,SGS,ISO

FFb oil yield: 22% CPO - FFB oil yield: 2% CPKO

Peanut is the main oilseed in the oil extraction market.many people will choose peanut oil press. we must understand the peanut oil processing. 1. Centrifugal oil filter machine capacity: 150-200kg/h, power: 4Kw, Voltage: 380V 2. Eliminates troubles of filtering cloth.

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil Extraction and Consideration of Solid Matrix as a By-Product or Intended Target

- Model Number: DT-03

- Voltage: 110v/220v/380v/440v

- Power(W): 10kw

- Dimension(L*W*H): 1010*780*960mm Max

- Weight: Peanut pressing equipment

- Certification: CE ISO BV

- Name: Peanut pressing equipment

- Color: Silver, red, yellow, green, blue

- Oil yield: 98%

- oil residual: 1-5%

- labor force: 3 persons

- land needed: different sizes

- Material: Stainless Steel 304

- Productivity: 1-2000TPD

- motor: Siemens

- maintenance: engineer service

- Use: Peanut pressing equipment

- Warranty: 2 Years

- Type: Peanut pressing equipment

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

The way of steaming, the effect is very good. In addition, when the press is pressed, the setting of the temperature of the oil press is also very important. If it is to make the oil taste strong, the temperature can be a little higher. If it is for the sake of good oil quality, it is recommended that the temperature be set at about 140 degrees.

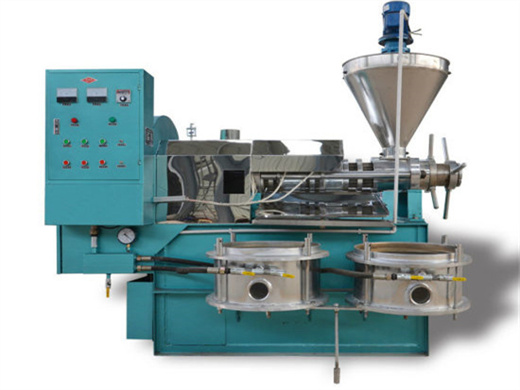

Peanut Oil Press-- Integrated Screw Oil Press for Both Cold Pressing & Hot Pressing

- Usage: Oil Extraction

- Type: Oil press

- Production Capacity: 60-80kg/h; 1.4-2 T/24hrs

- Voltage: 380v, 380v

- Dimension(L*W*H): 146*86*146cm

- Weight: 450 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Model: SY-RF85

- Power: 7.3kw

- G.W: 450kg

- Capacity: 60-80kg/h; 1.4-2 T/24hrs

- Packing: wooden case

- Function: Press Oil Seeds

- Press type: Screw Cold Oil Press

- After-sales Service: Online Video Services

- MOQ: 1 Set

Cold Pressing Peanut Oil: Integrated Screw Oil Press Advantages. 1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, peanut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the.

In this study, peanut oil was prepared by cold pressing (temperature under 60 C), hot pressing (temperature above 105 C), and enzyme-assisted aqueous extraction technology. Influences of an extraction technology on the oil fatty acid composition and the content of minor bioactive compounds, including tocopherols, polyphenols, and squalene, were investigated in detail.

What are the common extraction methods of extracting peanut oil in peanut oil processing process?_Blog - cooking oil making machine

- Type: vegetable oil machinery prices

- Use: vegetable oil machinery prices

- Certification: ISO9001

- Model Number: LD819

- Product name: vegetable oil machinery prices

- Production Capacity: 10-3000TPD

- Voltage: 220V/380V

- Power(W): According to your Capacity

- Dimension(L*W*H): depend on the mode

- Weight: depend on the mode

- Item: vegetable oil machinery prices

- Water content in press cake: 40%

- Oil extract rate: 21-23%

During peanut oil processing process, the most widely used extraction methods for commercial or industrial use are solvent extraction method and mechanical pressing method. These two methods have the characteristics of high extraction rate.

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- How to filter peanut oil?

- Food-grade filter cloth is adopted (interception size is 200 mesh) to filter the crude oil at least twice, and the filter temperature is controlled between 10 and 50°C (30°C is preferred); the pressured required during filtration is 0.1?0.4 MPa (0.3 MPa is preferred). The obtained product is cold extracted peanut oil ( Fig. 3.7 ). Figure 3.7.

- Certification: SGS,CE,ISO