palm oil expeller with oil filter press in ghana

- Model NO.: CRO429

- Customized: Customized

- Warranty: 2 Years

- Feature: High Oil Yield Efficiency

- After Warranty Service: Online Support, Field Maintenance and Repair Servi

- Automatic Grade: Automatic

- After-Sales Service: Free Spare Parts, Online Support

- Warranty of Core Components: 5 Years

- Capacity: 1-1000tons

- Advantage: Easy Operation

- Material: S.S for Deodorization Pot, Others in Carbon Steel

- After-Sales Service Provided: Rovided: Engineers Available to Service Machinery

- Weight: According to Your Capacity

- Transport Package: Packed in Wooden Cases

- Specification: depends on the machine

- Production Capacity: 30-1000tpd

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

manufacturers & exporters of palm kernel, sheanut, soybean oil expellers, oil milling machinery, edible oil refinery, solvent extraction plant in Accra, Ghana +91 9780771062, +91 92163-00009 [email protected]

Palm Kernel Oil Mill Manufacturer & Exporter - Hongde SCREW PRESS

- Usage: Cooking Oil Making Machine

- Type: Palm & Palm Kernel Oil Pressing Machine

- Automatic Grade: Automatic

- Production Capacity: 10 TONS /DAY

- Voltage: 30 HP

- Dimension(L*W*H): 2400MM*695MM*1979MM

- Weight: 5500 KG

- Marketing Type: New Product 2020

- Warranty of core components: 5 years

- Core Components: Motor, Gear, Bearing, Gearbox

- Oil type: Palm Oil, Palm Kernel Oil

- After-sales Service Provided: Engineers available to service machinery overseas

- Extraction of Oilseeds: Palm Kernel ,Palm

- Model Number: VK-100

- After Warranty Service: Spare parts

- Certification: ISO / CE/ D&B

Oil Expeller / Oil Press. Palm kernels contain 45 50% oil content. To achieve maximum oil yield, it requires 2 stage pressing. The residual meal / cake obtained from the 1st pressing is transferred to the 2nd screw press for final crushing. After a 2 stage pressing, a residual oil of less than 7% is left in the Palm Kernel Cake (PKC) which.

Tel: 237-39.14.22; 93.96.85. SERMI manufactures complete palm oil and palm kernel oil mills to order. The company works with private farmers having an average holding of 1 500 ha and design custom-made medium-scale plants for the estates. Twin-screw type presses are manufactured and supplied to medium-scale processors.

Oil Expeller, Vegetable Oil Extraction Plant Manufacturers

- Usage: Palm oil, Palm oil

- Production Capacity: 98%-100%

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2100*900*1800mm

- Weight: 140-900kg

- Marketing Type: Other

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Engineers available to service machinery overseas, Field installation, commissioning and training, Video technical support, Online support

- Product name: Screw Press Oil Expeller

- Material: Carbon steel or stainless steel

- Raw material: Palm, Palm Kernel

- Supply power: 380V/50HZ/3P

- Advantage 1: High Efficient

- Residual oil rate: 6-8%

- Delivery: 30 working days

- Capacity: 40-600kg/h

- After Warranty Service: Video technical support, Online support

- Local Service Location: None

- Certification: CE ISO

We are a leading manufacturer and exporter of Complete Mechanical Oil Extraction Plant, Solvent Extraction Plant, Cooking Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Palm Kernel & other Oil Expeller Spare Parts and EFB, MSW, Plastic & Industrial Shredder. Exported to 60+ Countries.

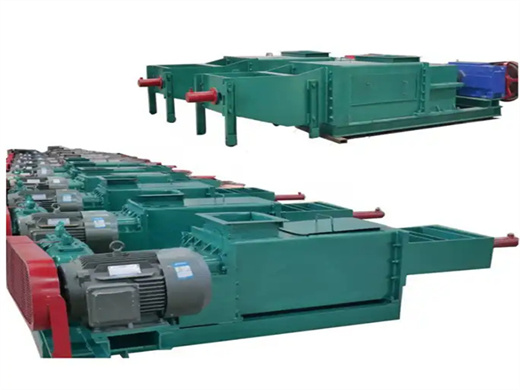

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

Palm Kernel Oil Expeller

- Slide Stroke (mm): customized

- Machine Type: Four-column Three-beam Hydraulic Press

- Ejector Force (kN): 500

- Return Force (kN): 400 kN

- System: Normal

- Year: new

- Voltage: 380V/220V Optional

- Dimension(L*W*H): Machine Size

- Weight (T): 10 T

- Model Number: YQ32

- Motor Power (kw): 22 kw

- Marketing Type: New

- Warranty of core components: 1 Year

- Core Components: Pump, Pressure vessel

- Product name: 500 ton Chocolate plate Stainless steel water tank hydraulic press

- Keyword: water tank making machine

- Type: 400 ton hydraulic press

- Model: four columns water tank making hydraulic press machine

- Usage: water tank press Machine steel cold extrusion Hydraulic Press

- Application: steel kitchensink,basin,bowl,pot forming machine

- Material: 45# Steel Material / Q235

- Function: steel forming,cold ertrusion forming.

- electric system: schneider

- motor: siemens

Palm kernel oil is a type of vegetable oil which is high in saturated fat and Omega 6, presenting serious health concerns. It is derived from the palm kernel, grown on the African oil palm tree. Oil palms originated in West Africa. Palm kernel oil is an important part of the oil market in the world, at present, it is more than 30% in the oil.

We bought Oil Mill Spare Parts in the year of 2010 " Mr. Abdul - Saudi Arabia "Recently Gagan International has supplied us Refinery Plant, the plant is running since more than a year ago and we have pleasure to certify that it is running to the higher than rated capacity with consistent quality. the plant has achieved the guarantees given by.

Hongde Screw Press - Oil Processing Machine Manufacturer and

- Usage: Palm Oil, Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 15 to 16 Tons/ Day

- Voltage: 50 HP

- Dimension(L*W*H): 2640t1396t3403

- Weight: 7000 KG

- Core Components: Motor, Bearing, Gearbox

- Oil type: Palm Oil

- Extraction of Oils: Palm Oil

- Capacity: 15 Ton Per24 Hour

- Motor: 50 HP

- Cooking Kettle: Single and Multi Stage

- Bearings: Heavy Duty

- Chamber: Steel Fabricated Chamber

- Worms and Cage Bars: Long Life

- Body: All Steel Fabrication

- Model Number: VIRAAT-160 (15 TPD)

Hongde GROUP is a leading Project Engineering Company established in 1971 and now a prominent name in the Oilseed's Oil Extraction Plant, Edible & Non-Edible Oil Processing Plants & Allied Industry. We are a Family Owned Company and Pioneer in Planning, Engineering, Manufacturing and Installation & Commissioning for Automatic Oil Mill Plant.

Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning. With our in-depth knowledge of the industry, our expertise and.

- Why palm oil processing machine is not available in Africa?

- Since many Africa customers, especially in Ghana, Nigeria, and other countries, requires relatively small scale palm oil making machine. But, most of the Palm Oil Machinery Manufacturers can’t supply the palm oil processing machine with such small scale capacity.

- Is a palm oil processing plant necessary in Ghana?

- Palm oil is one of the major sources of edible oil. It is extracted from a fleshy mesocarp of the palm fruit. Setting up a palm oil production plant isnecessarysince global demand is on the rise. But there are many requirements for setting up a palm oil processing plant in Ghana which demands a feasibility study.

- What is expeller pressed palm oil?

- The expeller pressed method was used during manufacturing. It contains no trans fats or artificial ingredients. Aside from baking, it also can be used for soap making. Palm oil is an edible vegetable oil derived from the mesocarp of the fruit of the oil palms. Photo Credit: Shutterstock Nativa’s palm oil is completely organic and unrefined.

- What is palm kernel oil expeller machine?

- The palm kernel oil expeller machine is also added with the seed frying and automatic heating function which changes the traditional heating method of cake grinding press, so as to shorten the preparatory work time, reduce the energy consumption & the abrasion of the machine and prolong the service time of expeller.