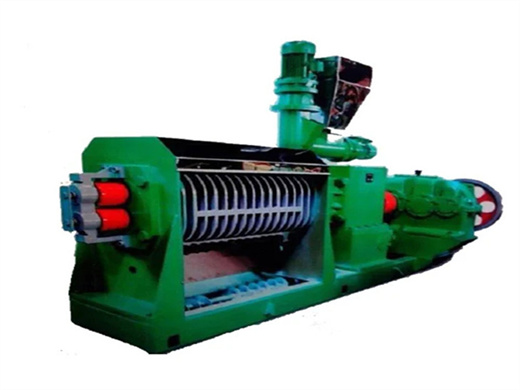

palm kernel press oil machine small cold oil maker in ghana

- Usage: Cooking Oil

- Type: Hot Pressing Machine

- Weight: 1300 KG

- Core Components: Other

- Oil type: Palm Oil

- Product name: screw oil press machine

- Application: Food Industry

- Advantage: High Efficient

- Color: Customers' Requirements

- Application range: Food Edible Oil Produce

- Keyword: Oil Press Machine

- Quality: High Level

- Package: Standard

- After-sales Service: Technology Supporting

- Brand: Eternalwin

1. Introduction. Oil palm (Elaeis guineensis Jacq.) cultivation is a core part of Ghana's agriculture.It has been selected by the government as a key strategic pillar of agricultural and industry-led growth for poverty reduction because of its potential to provide income for many rural smallholders [1].

Ghana is noted to be the third major palm oil producing country in Africa, and the sector plays an important role in rural livelihoods and local economic development. Artisanal and small-scale palm oil producers occupy a greater share of Ghana’s palm oil processing industry, producing 60?80% of the country’s palm oil. However, the.

palm kernal oil extractor machine in ghana

- Usage: Palmeed,soyabean,Palm etc.

- Type: canola oil presser

- Production Capacity: high

- Model Number: canola oil presser

- Voltage: 220V, 220V/ OTHER

- Power(W): 7.5kw

- Dimension(L*W*H): 1950x1300x1900

- Weight: 1100kg

- After-sales Service Provided: No overseas service provided

- Application: oil press

- Warranty: One Year

- Material: Carbon Steel

- Feature: cold and hot press

- Function: screw

- Capacity: 80-600kg/h

- Model: 6YL

- Price: Negotiable

Type: Cold Pressing Machine. Production Capacity: 3.6-6t/24h. Voltage: 380v. Dimension (L*W*H): 2400mmx1700mmx2000mm. Raw material: Stainess Steel. Product Color: blue/Gray. In Ghana, the oil palm has assumed increasing importance as a non-traditional export commodity. An estimated total land area of 305, 758 hectares is under oil palm.

The palm oil and kernel processing industry in Ghana includes large, medium-sized, and small-scale processors. The sector provides income for many peri-urban and rural populations and comprises small-scale processors working either in groups or as individuals (Ofosu-Budu & Sarpong, Citation 2013 ).

Palm Kernel Oil Mill for Cold Pressing of Palm Kernel Oil

- Type: Heat Press Machine

- Plate Type: Flatbed Printer

- Model Number: TH-100A

- Usage: hanger

- Color & Page: single color

- Voltage: 220V/50HZ

- Dimensions(L*W*H): 1300x800x1450mm

- Weight: 265 KG, 265kgs

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Bearing

- Platen Size: 100x100mm

- Driven Type: Pneumatic

- Model: TH-100A

- Color: gold or sliver

- Heat stamping size: 80x80mm

- Operation: Automatic

- Control system: PLC+touch screen

- Loading system: Automatic

- Unload system: Automatic

- Printing Speed: 1200pcs/hr

- Dimension: 1300x800x1450mm

Automatic double-shaft palm kernel oil mill can squeeze out most of the oil from fresh palm kernels by the high mechanical pressure. Palm kernel oil extraction machine has a large processing capacity and high oil yield which is special for crushing palm kernels, and its service life is three times higher than other ordinary oil press equipment.

A vertical oil palm digester design was made to feed the screw press by gravity. Detailed design of the screw press hereby presented. Much emphasis was however made in the use of available local.

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 150-230kg/h

- Voltage: 220v

- Dimension(L*W*H): 1800x1200x1500mm

- Weight: 1100 KG

- Core Components: Motor, Pressure vessel, Pump

- Oil type: Palm Oil

- Product name: Oli Press Machine

- Color: Customer's Request

- Model: SLX-100

- Advantage: Energy Saving Low Residual

- Advantage 2: Pure Essential Oil

- Application: Edible oil manufacturing

- Processing Types: Screw Pressing

- Used for: Edible Oil Making

Palm kernel oil is a type of vegetable oil which is high in saturated fat and Omega 6, presenting serious health concerns. It is derived from the palm kernel, grown on the African oil palm tree. Oil palms originated in West Africa. Palm kernel oil is an important part of the oil market in the world, at present, it is more than 30% in the oil.

The Model 6yl-130 palm kernel oil press machine is a reliable and high-capacity machine that is ideal for small farms of 3-15 hectares. It can process supplied materials from outside for individual household or pre-pressing in submerging oil workshops. This machine is favored by large and medium-sized oil extrusion workshops due to its.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: isolation technology applicable for Palm etc

- Type: isolation of protein from extracted Palm cake

- Production Capacity: 30-500T/D

- Voltage: Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Warranty of core components: 1 Year

- Core Components: Motor, PLC

- After-sales Service Provided: Engineers available to service machinery overseas, Online support

- Capacity: 30-500T/D

- Processing Material: Palm cake

- Function: making Palm oil

- material: carbon steel

- Palm oil color: yellow

- Palm oil line: Palm oil pressing and refinery

- After Warranty Service: Online support

- Local Service Location: Thailand, Bangladesh, Kazakhstan, Nigeria, Uzbekistan

- Certification: ISO9001:2000

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

- What is palm kernel oil extraction machine?

- Automatic double-shaft palm kernel oil expeller can squeeze out most of the oil from fresh palm kernels by the high mechanical pressure. Palm kernel oil extraction machine has a large processing capacity and high oil yield which is special for crushing palm kernels, and its service life is three times higher than other ordinary oil press equipment.

- Do small-scale palm oil processing units in Ghana have a weak milling capacity?

- Other centres do not even have milling machines. The women rely on primitive ways or travel long distances within the district to mill their palm fruit. This infrastructural challenge confirms the work of Angelucci ( 2013) that shows small-scale palm oil processing units in Ghana have weak milling capacity.

- What are the uses of palm kernel oil press?

- It is suitable for making animal feed, fertilizer, fuel or protein extract. Our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

- What is palm kernel oil expeller machine?

- The palm kernel oil expeller machine is also added with the seed frying and automatic heating function which changes the traditional heating method of cake grinding press, so as to shorten the preparatory work time, reduce the energy consumption & the abrasion of the machine and prolong the service time of expeller.