palm kernel oil processoring plant in zambia

- Usage: Palm OIL

- Production Capacity: High

- Dimension(L*W*H): 16*4.2*6.6 ft

- Weight: 24500 KG

- Machinery Test Report: Not Available

- Video outgoing-inspection: Not Available

- Warranty of core components: Other

- Core Components: Other

- Raw material: Palm, Palm Kernel

- Name: Oil Mill Machine

- Application: Palm Oil Processing Plant

- Feature: High Oil Yield Efficiency

- Certification: ISO

- Product name: Oli Press Machine

- Function: Making Palm Oil

- Advantage: Energy Saving Low Residual

- Keyword: Seeds Oil Pressing Machine

- After-sales Service Provided: YES

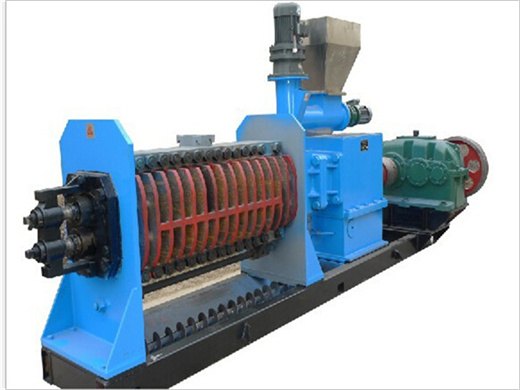

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. The nut processing and oil extraction is undertaken in the dry season when the pressure to obtain raw materials has subsided. The traditional palm oil processing starts with the shelling of the palm nuts.

Palm oil: Processing, characterization and utilization in the

- Type: oil centrifuge

- Product Type: palm oil separator

- Warranty of core components: 1 Year

- Core Components: PLC, Bearing, Motor

- Voltage: 380v/220V/415V

- Power: 4KW

- Weight: 550KG

- Dimension(L*W*H): 865*645*1100

- keyword: disc stack palm oil / Palm oil / Palm oil centrifuge

- name: disc oil centrifuge

- application: Palm oil, vegatable oil

- Control system: PLC control box

- Pump pressure: ≥0.2MPa

- Operation: automatic operation

- Bearing: SKF Bearing

- Function: separate the solid and water from oil

- materials: 304/ 316L SUS

- discharge way: automatic

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: Indonesia, Pakistan, India, Russia, Ukraine

- Certification: ISO

The oil palm tree is an ancient tropical plant that originated from West Africa. Palm oil has centuries? long use as food and medicine. This review covers the recent significant materials found in the literature on palm oil processing, refining, and use in frying especially in blends with other vegetable oils.

3.1.4 Digestion of the fruit. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Oil palm in the 2020s and beyond: challenges and solutions

- Usage: Press Oil

- Production Capacity: 150-200kg/h

- Voltage: 380V,3Phase , 50HZ

- Dimension(L*W*H): 1900*1100*1500mm

- Weight: 986 KG, 986kg

- Warranty of core components: 1 Year

- Core Components: Gear, Bearing

- Capacity: 150-200kg/h

- Size: 1900*1100*1500mm

- After Warranty Service: Spare parts

There are two contrasting types of oil found in the two principal tissues of palm fruits, namely ‘palm oil’ and ‘palm kernel oil’ (Murphy 2019).Palm oil, extracted from the fleshy mesocarp tissue, is a deep orange-red, semi-solid fluid, whilst palm kernel oil is a white-yellow oil that is extracted mainly from the endosperm tissue of the kernel (seed).

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding.

Sustainable Practices of IOI Palm Oil and Palm Kernel

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, mill machine

- , Full/semi Automatic

- Production Capacity: 100%

- Model Number: LDSW12

- Voltage: 220V/380V

- Power(W): 70-150kw

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- Name: Jinan,Shandong LD making edible Palm Oil press manufacture

- Dimension: standard

- Capacity: 10 ~2000T/D

- Main Material: Carbon Steel /stainless steel

- Color: As your demand

- Certificate: CE&ISO9001

- Quality Control: X-ray Detection

- Warranty Period: One Year

As part of the palm oil supply chain, IOI Edible Oils Sdn. Bhd. (IOIEO) plays a vital role in processing crude palm oil, and palm kernel. IOIEO strives to improve its operations and is committed to reducing its carbon footprint. Improvements are made by heat recovery, water reuse, implementing process changes and installing new equipment.

The quality of crude palm oil is dependent on the care taken after harvesting, particularly on the handling of the FFBs. Figure 1. Fresh fruit bunches waiting for processing at palm oil mill. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 60-100 tons.

Palm Kernel Oil Refinery

- Model NO.: 6YL-A

- Customized: Non-Customized

- Warranty Period: 1 Years

- Quality: China Best Brand and Quality

- Model Number: 6yl

- Oil Rate and Lever: Oil Yield≥98%, Cake≤5%

- Raw material: Palm, Palm Kernel

- Material: Stainess Steel

- Function: Making Edible Oil

- Power: 5.5-18.5kw

- Weight: 140-1050kg

- Transport Package: on Sea

- Specification: depend on capacity

- HS Code: 5911400000

- Production Capacity: 300 Sets /Month

Tinytech Palm Kernel Oil Refinery Plant is specially designed and built for processing the Palm Kernel Oil. As you know, palm kernel oil is also referred to as PKO. This oil is obtained from the kernel seeds of the oil palm fruit. The process of extracting the palm kernel oil is through mechanical pressing. The output of seed extraction is the.

Palm nut cracking and oil expression accounted for 73.4% of the energy consumed in both small mill and medium mills respectively and 85.2% in the large mill. This indicates that these two unit.

- How to set up a palm kernel oil production plant?

- Setting up a palm kernel oil production plant, many aspects must be taken, including production capacity and requirements of customers, the quality of the final produced palm kernel oil, palm kernel oil processing technology, and more.

- What is zampalm ? Zambia’s first palm plantation?

- LUSAKA, ZAMBIA ? Zampalm in Mpika is Zambia’s first ever palm plantation. The plantation boasts 2,800 hectares of palm plants, which when harvested will produce crude palm oil that is the basic ingredient in most vegetable oils on the market in Zambia.

- Can palm oil from Zambia cut back on crude oil imports?

- The plantation boasts 2,800 hectares of palm plants, which when harvested will produce crude palm oil that is the basic ingredient in most vegetable oils on the market in Zambia. The locally produced palm oil will enable government to cut back on crude palm oil imports which currently stand at over US$70 million annually.

- What is zampalm in Mpika?

- Zampalm in Mpika is Zambia’s first ever palm plantation. The plantation boasts 2,800 hectares of palm plants, which when harvested will produce crude palm oil that is the basic ingredient in most vegetable oils on the market in Zambia.