palm kernel oil plant machine pictures in lusaka

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm s oil press machine japan

- Production Capacity: 450-7000kg/h

- Model Number: 6YY-260

- Voltage: According to customer demand

- Power(W): 1.5KW

- Dimension(L*W*H): 1050*950*1650

- Weight: 850kg

- Color: Silver

- Production condition: One staff, plant 10㎡

- Material: Carbon steel, stainless steel

- Raw material: Palm, Palm Kernel

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Hydraulic

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

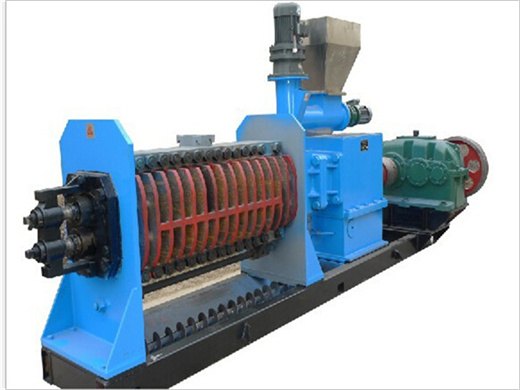

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil.

KERNEL RECOVERY STATION EQUIPMENT LIST: 1.Nut Auger conveyor 2.Destoner Column c/w Fan,Ducting and Airlock 3.Nut Grading Drum 4.Nut Hopper c/w structure 5.Nut Vibrating Feeder 6.Super Craker (Ripple Mill) 7.Steel Support,Maintained Platform 8.Cracked Mixture Conveyor 9.Cracked Mixture Elevator 10.Winnowing System No.1&2Cyclone&Ducting 11.

Palm Kernel Crushing Machine | Palm Oil Waste Treatment Plants

- Usage: Small Palm oil machine

- Production Capacity: 1TPD

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 920 x 390 x 750mm

- Weight: 150kg

- Core Components: Gearbox

- Price Level: Low price

- Function: Making edible oil

- Raw material: Palm, jatropha , hemp , Palm

- Machinery type: Single screw ginger oil making machine

- Advantage: Low investment & High oil output

- Accessory: Sufficient and cheap spare parts are available

- Feature: Multifunction high efficient Palm oil machine

- After Warranty Service: Online support

- Local Service Location: Egypt, Canada, United States, Italy, France, Germany, Viet Nam, Philippines, Indonesia, Pakistan, India, Mexico, Spain, Thailand, Australia, Morocco, Kenya, Argentina, South Korea, UAE, Colombia, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan

- Certification: CE ISO Palm oil machine

300 tons per 24 hours. 250 tons per 24 hours. 200 tons Ext 250 tons per 24 hours. 150 tons Ext 250 tons per 24 hours. Muar Ban Lee Group is a palm kernel crushing machines and palm oil waste treatment plants manufacturer specializes in palm kernel crushing machines and waste treatment.

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

BEST Palm Kernel Crushing Machine | Palm Kernel Processing Plant

- Usage: Palm oil

- Production Capacity: 50-500kg/h

- Voltage: 220V/380V (customization)

- Dimension(L*W*H): 740*1010*1640 mm

- Weight: 1230 KG

- Core Components: Motor, Hydraulic system

- Oil type: Palm Oil

- Name: Hydraulic cold oil press Palm Kernel Oil processing machine

- Application: Oil Production Line

- Advantage: High Oil Output

- Capacity: 800 kg/h

- Keyword: hydraulic cold oil press

- Package: Wooden case/Customizatoin

- Application range: Oil s

- Working pressure: 60 Mpa

- Use for: Pressing high quality oil

- After Warranty Service: Video technical support

The main machines used in palm kernel oil extraction plant include nut & fiber separating machine, palm kernel crushing machine, cooking machine, palm kernel oil extraction machine (mechanical screw pressing), oil filter press machine, etc. Nut & Fiber Separation: It is also known as palm kernel recovery. Palm Kernel Crushing: Toothed Roll.

Based around our advanced, 3-phase PANX decanter, Alfa Laval D3 PRO is the industry’s only all-in-one processing solution that can process undiluted crude palm oil with consistent performance, even at high capacities. D3 PRO requires no dilution water, meaning a reduction in water and effluent of up to 20% and major OPEX savings from day one.

Palm and Palm Kernel Oil Production and Processing in Malaysia and Indonesia

- Usage: home use oil mill

Production Capacity: 100% - Voltage: 380V

Power(W): 2KW - Dimension(L*W*H): 1650*1200*1720

- Weight: 630

Main engine power: Y160L-6-5.5KW - Vacuum pump power: Y90S-4-0.55KW

Residual oil rate: 6~7% - Raw material: Palm, Palm Kernel

- Function: Cold/Hot Press

Advantage: Energy Saving - Feature: High Output

- Application: home use oil mill

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding.

Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil.

Palm kernel - Wikipedia

- Model Number: small scale Palm oil machine

- Type: Grain Processing Equipment

- After-sales Service Provided: Overseas service center available

- Name: Palm press machine

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Palm machine

- oil rate: 20%-98%

The palm kernel is the edible seed of the oil palm fruit. The fruit yields two distinct oils: palm oil derived from the outer parts of the fruit, and palm kernel oil derived from the kernel. [1] The pulp left after oil is rendered from the kernel is formed into "palm kernel cake", used either as high-protein feed for dairy cattle or burned in.

BTMA Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut. With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process design, oil mill machinery manufacture, plant layout, installation and debugging, and technical guidance.

- How do palm kernel machines work?

- The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil seeds. The oil that is expelled then seeps through the small openings into a container. These openings are very small which prevents any kind of solid material or residue from the seeds to mix with the extracted oil.

- What is a palm kernel oil expeller / palm kernel screw press?

- Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber.

- Which machine is used for palm kernel cooking?

- The main machine for palm kernel cooking is steam cooker. Palm Kernel Oil Extraction/Pressing – Screw Oil Press The oil is extracted from pretreated palm kernel through mechanical forces.

- What are the different types of palm kernel machines?

- The nutcracker, kernel/shell separator and palm kernel expeller are produced to handle palm kernel. The expeller has machined flights on a single shaft with threaded backpressure cone. Generally machines are produced having a 1 tonne/hr capacity for palm oil while the palm kernel machines have rated throughputs of 150-250 kg/hr.

- Voltage: 380V