palm kernel oil extractor for nepal in togo

- Usage: Palm OIL, Cooking Oil

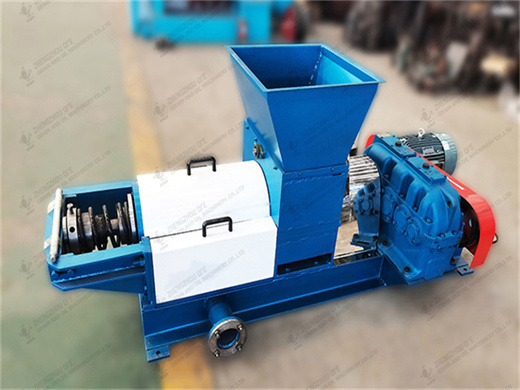

- Type: Cooking Oil Press Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Dimension(L*W*H): Standard

- Weight: 60000 KG

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine

- Oil type: Palm OIL

- Commodity: Cold Pressed Palm Oil Press Machine

- Certification: CE,ISO

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

The cooked palm kernels are then fed into a screw press machine, which uses a rotating screw to apply pressure and extract the oil. The oil is squeezed out of the kernels and collected in a container. Step 2. Clarification. The extracted oil is then passed through a clarifier to remove any solids or impurities.

Betting on Palm Oil - World Bank Group

- Usage: waste oil to biodiesel plant

- Production Capacity: 5~100T/D

- Model Number: BIODIESEL

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): 1360*950*1170mm

- Weight: up to specification

- Function: waste oil to biodiesel plant machine

- Capacity Model: 5~100T/D

- Suitable material: Palm

- Patent product: Yes

- Patent No.: ISO9001

- Fully automatic: Yes

- Technology: Top technology in China

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

Many more women are now interested in palm oil production which has become less arduous and more lucrative. ASSAHOUN, November 19, 2013 - In Togo, the oil palm tree is of special importance and the products derived from it, notably, palm oil (extracted from the pulp) and palm kernel oil (extracted from the kernel), are highly valued.

With the above data, the crude palm oil extraction efficiency of the screw press, that is, the ratio of the quantity of crude palm oil extracted to the quantity of palm kernel fruits fed in was 75.

Oil palm in the 2020s and beyond: challenges and solutions

- Usage: vegetable oils and animal oils

- Type: Batch oil refinery plant

- Production Capacity: 98%-100%

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 15*10*8m3

- Weight: KG

- Marketing Type: Factory Direct Sales

- Warranty of core components: 1 Year

- Core Components: Motor

- After Warranty Service: Online support

- Color: Green/White/Red/Yellow

- Capacity: 1-10 tons per day mini oil refinery

- Raw material: Palm, Palm Kernel

- Material: Stainess Steel

- Function: Making Palm oil

- Advantage: High efficient mini oil refinery

- Spare parts: Cheap and sufficient spare parts available

There are two contrasting types of oil found in the two principal tissues of palm fruits, namely ‘palm oil’ and ‘palm kernel oil’ (Murphy 2019).Palm oil, extracted from the fleshy mesocarp tissue, is a deep orange-red, semi-solid fluid, whilst palm kernel oil is a white-yellow oil that is extracted mainly from the endosperm tissue of the kernel (seed).

The oil yield of 34.2% was obtained in the extraction condition of the ratio of palm kernel to ethyl acetate of 1:7, the rotational speed of 5000 rpm, and 10 minutes extraction time.

Palm and Palm Kernel Oil Production and Processing in

- Type: Screw

- Configuration: Stationary

- Power Source: AC POWER

- Lubrication Style: OIL-LESS

- Mute: Yes

- Dimension(L*W*H): 1000*700*830(mm)

- Working Pressure: 0.8 bar

- Marketing Type: Ordinary Product

- Warranty of core components: 1 Year

- Core Components: Bearing

- Gas Type: Air

- Inlet valve: Hoerbiger

- Colour: Red/White

- Drive mode: Direct drive/Belt drive

- Cooling mode: Air cooling

- Bearing: world famous brand

- Faygo: FaygoPlast is famous China Plant

- Weight: 210kg

- Voltage: 380v(according to customer)

- Capacity: 1.2m3/min

The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?23% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B.

Palm kernel oil. Palm kernel oil is an edible plant oil derived from the kernel of the oil palm tree Elaeis guineensis. [1] It is related to two other edible oils: palm oil, extracted from the fruit pulp of the oil palm, and Palm oil, extracted from the kernel of the Palm. [2]

Applications of Supercritical Fluid Extraction (SFE) of Palm

- Usage: Palm

- Production Capacity: 75-150Kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 900*1100*1650mm

- Weight: 2000 KG

- Warranty of core components: 1 Year

- Core Components: PLC

- After-sales Service Provided: Online support

- Certification: CE Certificate

Abstract. Supercritical fluid extraction (SFE), which has received much interest in its use and further development for industrial applications, is a method that offers some advantages over conventional methods, especially for the palm oil industry. SC-CO 2 refers to supercritical fluid extraction (SFE) that uses carbon dioxide (CO 2) as a.

Palm Kernel Extraction. The residue from the press consists of a mixture of fibre and palm nuts. The nuts are separated from the fibre by hand in the small-scale operations. The sorted fibre is covered and allowed to heat, using its own internal exothermic reactions, for about two or three days. The fibre is then pressed in spindle presses to.

- What is palm kernel extraction?

- Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying.

- What is palm oil extraction machine?

- Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill.

- How is palm oil extracted?

- Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil.

- How is palm kernel oil made?

- The sorted fibre is covered and allowed to heat, using its own internal exothermic reactions, for about two or three days. The fibre is then pressed in spindle presses to recover a second grade (technical) oil that is used normally in soap-making. The nuts are usually dried and sold to other operators who process them into palm kernel oil.