oil press plant sunflower oil extraction plant in nepal

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: above 90%

- Voltage: 220V/110V

- Dimension(L*W*H): 56x26.5x33cm

- Weight: 12 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Product name: oil extractor machine

- Machine size: 56x26.5x33cm

- Control mode: Full Automatic

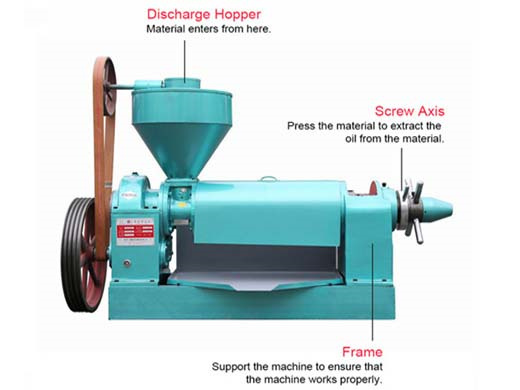

- Squeezing type: screw type

- Function: Oil Pressing

- Production: 40-600kg/H

- used for: Sunflower,avocado,mustard,Sunflower,ect

- Material: SS materials body 316 stainless steel screw and chamber

- keep working: 12 hours

- Certification: CE

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Usage: Sunflower/oilseeds

- Production Capacity: 100% new type neem oil press machine

- Model Number: 6YL

- Voltage: 220V/380V/440V

- Power(W): 5.5~18.5KW

- Dimension(L*W*H): 1950*1300*1900, according to the capacity

- Weight: 950KG

- Certification: ISO9001/CE/BV

- Raw material: Sunflower Seed

- Name: new type neem oil press machine

- Application: Oil Pressing

- Common capacity: 80-600kg/h

- Warranty: One Year

- Character: Screw Oil Pressing Machines

- decoloring time: 15-20min

- Moisture: 3%

- residual oil in cake: 2%

After the centrifugal decanter, the prepress oil is typically in the range of 0.1% solids content and 0.2% moisture content. If the pre-press oil has to be degummed, it is generally mixed with the.

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Sunflower Oil Production Plant Process Flowchart - Hongde GROUP

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 5T/H-100T/H - Voltage: 380v/220v,50hz,three phase

Certification: ISO,SGS,CE - product name: Sunflower oil miller equipment

application: FFB processing plant - Sunflower furit oil yeild: 20-22%

- Sunflower kernel oil yield: 2%

buisness scrop: FFB production,CPO and CPOK oil refinery plant - market: Indonesia,Malaysia,Nigera,

- capacity: 5T/H-1000T/H

work time: 8-24h/d - delivery time: 60-90days

- certification: Ce,ISO,SGS

The Sunflower Oil Processing Plant offered by Hongde is robust, versatile, reliable and efficient. This Sunflower Oil Processing Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical. Please fill the below Enquire Now Form so that we can contact and provide you the best.

To be specific, oil-used sunflower seeds contain 45%~60% of the oil which is suitable for the pre-pressing and leaching method: In the 1 st, the raw seeds are pre-squeezed by means of a continuous screw press. The 2 nd extraction type is solvent extraction, and the commonly used solvent is mainly hexane-based solvent VI or other solvents such.

Sunflower Oil Refinery Plant Process

- Usage: Sunflower Oil, Cooking Oil

- Type: Seed Roaster

- Production Capacity: 50-1000kg/h for Sunflower Oil Extruder Machine

- Voltage: 220V/380V

- Dimension(L*W*H): 1550*1780*1230 mm

- Weight: 1000 KG

- Warranty: 2 years

- Warranty of core components: 2 years

- Core Components: Motor, Other

- Oil type: Sunflower Oil

- Product name: : Sunflower Oil Extruder Machine

- Material: : Stainless steel for Sunflower Oil Extruder Machine

- Function: : For puffing food making

- Bearing: : SKF for Sunflower Oil Extruder Machine

- Processing Technology: : kneading/cooking /extruding

- Raw material: : Sunflower Meal/Sunflower

- Warranty: : 2 Years for Sunflower Oil Extruder Machine

- Color: : Can be customized according to customer requirements

- Driven type: : Electricity or Diesel for Sunflower Oil Extruder Machine

The steps involved in Sunflower Oil Refining Process: Degumming. Neutralization. Water Washing. Vacuum Drying. Bleaching. De-waxing. Deodorisation. The chemical refining stages of Sunflower oil are also similar to other soft oils except dewaxing which is additional as sunflower oil contains wax which will be removed by dewaxing process.

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

Sunflower Oil Extraction Plant | Sunflower Oil Machine

- Usage: Cooking Oil, Sunflower Oil and so on

- Production Capacity: 10T/24h

- Voltage: 380V

- Dimension(L*W*H): 2010*690*1430mm

- Weight: 80600kg

- Warranty: 1 Year, 12 Months

- Core Components: Pressure vessel, Gear, Bearing, Gearbox

- Oil type: Sunflower Oil

- Raw material: Sunflower/ Seasame/ Sunflower seed/

- Function: Oil Pressing

- Application: Screw Oil Expeller

- Color: Customized

- Material: Stainess Steel

- Feature: High Oil Yield Efficiency

- Used for: Oil Processing

- Product name: High performance screw Sunflower oil processing machine

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: France, Philippines, Brazil, Peru, Indonesia, India, Spain, Thailand, Australia, Kenya, Argentina, Chile, UAE, Colombia, Sri Lanka, Bangladesh, Ukraine, Kyrgyzstan, Uzbekistan

- Certification: CE/OHSAS

Sunflower Filter Press. The filter press filters the extracted sunflower oil by using the micro filter cloths to make it edible. Filtered sunflower oil will be a very cleaned, transparent, fresh, pure and natural in taste without any chemicals and hence there is a big demand of the same sunflower oil at everywhere.

The volatile flavors of tea oil, olive oil, soybean oil, corn oil, peanut oil, sunflower oil, sesame oil, and rapeseed oil were compared using solid phase micro-extraction-mass spectrometry, and it was found that olive oil contained the largest amount of esters, and the other EPOs had high amounts of aldehyde (Hu et al., 2018).

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- How to extract oil from sunflower seeds?

- The Oil extracted from sunflower seeds either by screw press or by solvent extraction process. The Seeds will be either de hulled or whole seed extraction is taking place based on the requirement of the protein content of the De oiled Meal. Preparation of Sunflower Seed for Solvent Extraction Process:

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- Voltage: 380v/220v,50hz,three phase