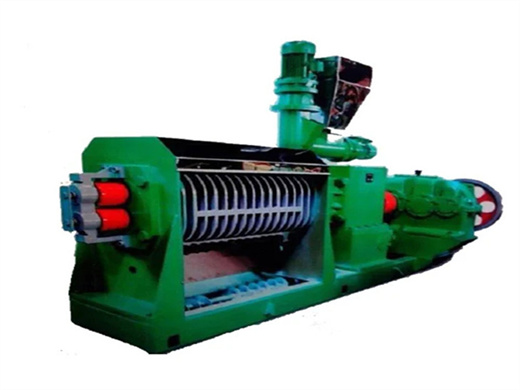

oil press machine|palm kernel oil press machine in indonesia

- Usage: commercial oil press machine

- Type: commercial oil press machine

- Production Capacity: 400~600kg/h

- Model Number: 6LD

- Voltage: 220V/380V

- Power(W): 18.5kw

- Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

- Raw material: Palm, Palm Kernel

- Advantage: Energy Saving

- Machine Material: Part of are stainless steel

- Warranty: 1year

- Residual: Less than5%

- Supplier strength: with 30 years experiences

- Machine color: According customer needs

- Business type: manufactory

The output of 6YL-95A palm kernel oil press is 200kg/h, and the motor power is 15kw. It is suitable for small oil mill. The 6YL-130A palm kernel oil press capacity is 500kg/h, and the motor power is 22kw. The bigger motor increases the working efficiency of the oil press. And this machine uses thickened and enlarged gears, which are more.

The complete set palm oil processing machine includes palm oil extraction process(how palm oil is extracted), palm kernel oil extraction process and palm oil/palm kernel oil refining process.Oil palm is an important tropic oil seed plant. The palm oil content is very high: common fresh fruit :45~50% , palm kernel :50~55%.

Palm oil press machine

- Usage: Palm/Palm oil making machine

- Type: Cold & Hot Pressing Machine, automatic oil extracting machine

- , Fully automatic

- Production Capacity: 10T-5000TPD

- Model Number: LD FIRST

- Voltage: 220V/380V/440V

- Power(W): 10kw-50kw

- Dimension(L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

- Name: automatic oil extracting machine

- Materials: Carbon steel Q235 and SS304

- Water consumption: ≤ 0.3 t/t Palm

- Power consumption: ≤ 12kwh/t Palm

- Operate people: 2-3

- Circulating Water Cooling Water Yield: 150M3/H

- Supplier Type: Manufacturer

- Finished product: Grade 1 cooking oil

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil.

Palm kernel oil is a type of vegetable oil which is high in saturated fat and Omega 6, presenting serious health concerns. It is derived from the palm kernel, grown on the African oil palm tree. Oil palms originated in West Africa. Palm kernel oil is an important part of the oil market in the world, at present, it is more than 30% in the oil.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 4.26 *1.55 * 3.52 ft

- Weight: 0 KG

- Marketing Type: Ordinary Product

- Warranty of core components: Other

- Core Components: Other

- After-sales Service Provided: Engineers available to service machinery overseas

- Raw material: Palm, Palm Kernel

- complete Warranty Service: Video technical support

- After Warranty Service: Spare parts

- On Site Warranty Service: Field maintenance and repair service

- Function: Making Palm Oil

- Product name: Oli Press Machine

- Application: Palm Oil Production

- Keyword: Mini Oil Expeller

- Keyword 1: Oil Making Press Machine

The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. Oil Capacity: 1~1000 Tons/Day. Oil Yield: >45%. Oil Residual in Cake:

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil.

Kumar’s Palm Kernel (PK) Series Oil Expeller Machine

- Usage: Palm Oil, Cooking Oil

- Voltage: 380V/50HZ

- Dimension(L*W*H): 4100x2270x3850

- Weight: 11500 KG

- Core Components: Gearbox

- Oil type: Palm Oil, tung , Palm beans, Palm Oi

- Product name: YZ/XZ32-2

- Capacity: 100-300 t/d

- Press: 8-10 %

- Pre-press: 14-18%

- Machinery type: Automatic screw oil mill machine

- Power: 110 Kw

- Use for: Oil press

- Press type: Screw cold hot oil press

- After-sales servise: Door to door

- Application range: Edible oil press

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

The working principle of palm kernel oil extraction machine. The palm kernel oil press mainly has a main engine plus power system. The main engine includes a screw press, a press chamber, and a spring, which is composed of a cake cone. Palm kernel oil press, also known as palm kernel screw press, is used to press oilseeds to extract oil from.

Palm Oil Processing Production Line

- Usage: crude animal fat oil refining plant

- Type: crude animal fat oil refining plant

- Production Capacity: 100kg/h, 500kg/h, 1tph, 5tph, 10tph

- Model Number: DT-ZYJ02

- Voltage: 220V/380V

- Power(W): 10-50kw

- Dimension(L*W*H): 46*32*12m

- Weight: 30tons

- Raw material: Palm

- Application: crude oil refinery

- Handling capacity: 5tpd-300tpd

- Power consumption: 18.8kw/h

- Steam consumption: 300kg/t

- Refinery rate: 96%

- Refinery method: Physical and Checmical

- Advantage: Energy Saving

When you plan to build an vegetable oil processing plant, please contact us today to get the quote. Hongde Machine provides complete palm oil processing solutions and equipment, palm fruit and kernel processing, crude palm oil processing, refining, fractionation, and wastewater.

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.