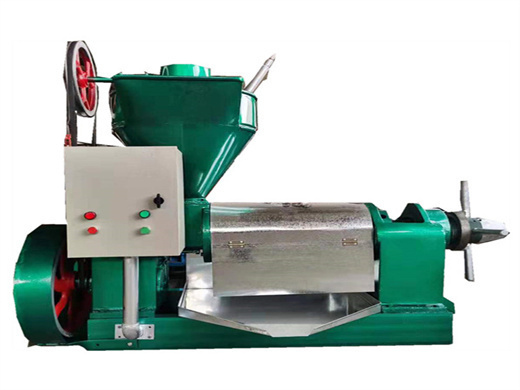

oil extraction machine for extracting soybeans in lagos

- Usage: for all oilseeds

- Production Capacity: 20-2000TPD

- Model Number: 015

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): standard

- Weight: standard

- Certification: CE,ISO

- Application: oil mill machinery prices

- Name: hydraulic oil press machine baobab seeds oil press machine

- Note: 2 years spare parts for free

- Oil pretreatment 1: cleaning section

- Oil pretreatment 2: Breaking section

- Oil pretreatment 3: Embryo pressing section

- Oil pretreatment 4: Softening section

- Pressing part: Oil pressing section

- Extration part: oil extractor

- Refining part: Whole line for oil refining

The standard soybean oil pressing production process includes multiple steps such as cleaning, crushing, softening, embryo rolling, steaming, pressing and filtering. Different types of oilseeds have different pressing production processes. The residual oil rate in the oilseed meal after pressing is generally about 6%.

The solvent extraction process is a common method used for soybean oil extraction. The aim is to use a solvent for dissolving a target solute, and wash it out of the solid plant component. The processes involved at this stage are provided below. Main Extraction. Soybeans are first cleaned and cracked.

Soybean Oil Processing Business Startup Cost and Project

- Usage: Soybean Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 98%-100%

- Model Number: Qie-20

- Voltage: 220V/380V/440V

- Power(W): 15KW

- Dimension(L*W*H): 6000*700*5600mm

- Weight: 3000KG, 1-30Tons

- Certification: ISO9001/CE/BV

- Raw material: Soybean Seed

- Name: Soybean oil refinery engine

- Warranty: One Year

- Character: Oil Processing Line

- Advantage: Energy Saving

- Common capacity(TPD): 1-100THD

- Material: Stainless Steel

- Certificate: ISO9001/CE/BV

- Export market: Global

Oil content of soybean is low, poor plasticity, so it is generally softened before flaking. Flaking temperature should depend on the level of moisture content of soybeans. Soybean moisture for 13% to 15%, softening temperature is usually mastered in 70 ~ 80 degrees, softening time 15 ~ 30 minutes.

We can supply the turn key project of soybean oil production plant, from flaking to extruding to solvent extraction to refinery and final package, processing capacity from 10T/D to 500T/D. Please inform us the capacity you want when you inquiry. Soybean oil extraction machine designed by Wintone Machinery adopts the most scientific oil.

Soybean Oil Extraction Machine - Myande Group

- Usage: Soybean Oil, All kinds of oil seeds

- Type: Cooking Oil Press Machine

- Production Capacity: 200KG/H Soybean oil press machine

- Voltage: 380v

- Dimension(L*W*H): 2160*525*780mm

- Weight: 500 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Soybean Oil

- 6YL-95/ZX-10 oil expeller: 200kg/h Soybean oil press machine

- raw material: Soybean

- Capacity: 200kg/h oil expeller

- main power: 7.5kw

- oil residue in cake: less than 7%

- matched machines: roaster,oil expeller,oil filter,oil refinery,packing machine

- working video: we can supply

- operation manual: we can supply

- warranty: 12months

Myande Group is China leading supplier of complete plants, equipment, and engineering services for soybean oil processing industry with capacity from 100TPD to 10,000TPD. We pride ourselves on having a cutting-edge manufacturing and R&D platform that ranks among the best in the world. With 120,000-square-meter facility and a talented team of.

Solvent extraction. In solvent extraction, flaked soybeans are washed with hot solvent, typically hexane, to separate the solids from the fats. Multiple washes dissolve the oil and carry it away. This oil solvent combination is also known as the miscella. The remaining material is the wet meal and solvent, also known as the marc.

Solvent extraction process of soybean - Edible Oil Expeller

- Usage: Soybean Oil

- Type: Seed Roaster

- Voltage: 220v, 110v/220v

- Dimension(L*W*H): 410x160x340mm

- Weight: 1400 kg

- Core Components: Oil Press Machine

- Oil type: Soybean Oil

- Product name: Oil Press Machine

- Model: ZY-28A

- Frequency: 50hz

- Net weight: 12kg

- power: 700w

- material: stainless steel

- Feature: High Oil Yield Efficiency

- Application range: Competitive Mini Oil Press Machine

- MOQ: 1PCS

The first stage is mainly to dissolve the oil in the damaged cells by solvent. The extraction amount is large and the time is short (15~30 minutes), and the total oil content can be extracted from 85% to 90%.In the second stage, solvents are needed to penetrate into the unspoiled cells for a long time with low efficiency.

The soybean oil extraction machine we provided is featured with high efficiency, low operational cost, easy operation and less maintenances. Our soybean oil press machine adopts mechanical pressure to squeeze oil out from the soybeans, so there are no chemical additives into the whole soybean oil extraction process and the oil obtained is more.

Extraction of oil from soybeans | Journal of the American Oil

- Usage: Soybean oil

- Type: Oil Extraction Machine

- Production Capacity: 50-500kg/h

- Voltage: 220V/380V/as your demand

- Dimension(L*W*H): 900*1000*1400mm

- Weight: 950 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Name: Homemade oil press machine india

- Raw material: Soybean

- Function: Oil Mill Making Pressing Extracting Machine

- Capacity: 50kg-1000kg/hour

- Feature: Multifunction High Efficient

- Processing Types: Hydraulic Pressing Cold Press

- Oil rate: Oil Yield 99%

- Power: 1.5kw

- Package: 900*1000*1400mm

- Material: Carbon Steel Stainless Steel

Modern processing plants extract soyabean oil by solvent liquid transfer. Soyabeans are cleaned, cracked, dehulled and conditioned into a thin flake before they enter the extractor. Extraction is by successive, countercurrent washes of hexane solvent. The extracted flakes are then carried by a sealed conveyor to be desolventized in enclosed vessels by application of jacket and sparge steam.

Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 20 % oil content. After a single stage pressing, about 5 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

- What is the process of soybean oil extraction plant?

- Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

- How to extract soybean oil?

- Soybean oil can be obtained by expelling or using an organic solvent. Although, the employment of solvent will always follow the expelling to increase lipid extraction yield .

- Which solvent is used in soybean oil production?

- Solvent extraction and expelling are the main processes used in soybean oil production. Hexane is currently the leading solvent in extraction , . This solvent has a high solubility for oil extraction, availability, low price, low boiling point, and heat of vaporization .

- Why is automatic soybean oil processing plant necessary?

- Automatic soybean oil processing plant is necessary because of the low efficiency of the oil extracted by hand operated machines.