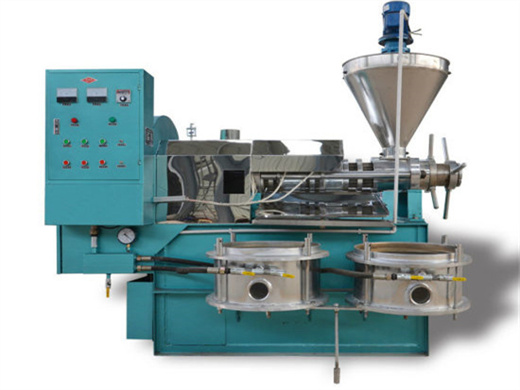

oil extraction equipment peanut machine in bangladesh

- Usage: Peanut oil extractor machine

- Type: Peanut oil extractor machine

Production Capacity: 400~600kg/h - Voltage: 220V/380V

Power(W): 18.5kw - Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

Certification: ISO9001 - Keywords: Peanut oil extractor machine

Raw material: Peanut - Advantage: Energy Saving

- Machine Material: Part of are stainless steel

Warranty: 1year - Residual: Less than5%

- Supplier strength: with 30 years experiences

Machine color: According customer needs - Product name: Peanut oil extractor machine

- Business type: manufactory

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

Oil extraction Oil contains high amounts of energy and fat-soluble vitamins (A, D, E, and K) and essential fatty acids. The oil content of the kernels is between 45% and 55%. The peanuts are prepared for the oil extraction process by being shelled and cleaned. Oil production requires some type of press with which to extract the oil form the.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut Oil

- Type: Peanut oil production companies in malaysia

- Production Capacity: 10-100TPH

- Model Number: DT100

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to Peanut oil processing capacity

- Certification: ISO9001/CE/BV

- Keywords: Peanut oil production companies in malaysia

- , long term technical support

- Plam kernerl oil press machine: Available

- Raw material: Peanut

- Feature: High efficient and environment protection

- Factory Area: According to the capacity and the actual situation

- Residual: Less than 2%

- Technology: Introduce Malaysia high technology

- Material: Parts of are stainless steel

- Product name: Peanut oil production companies in malaysia

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Peanut Oil Extraction Machine. Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs.

Groundnut Oil Mill / Extraction Plant Manufacturer & Exporter

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 20-2000T/day - Voltage: 380V

Power(W): Standard - Dimension(L*W*H): Standard

- Weight: Standard

Certification: CE,ISO - Commodity: Peanut Oil Refinery Plant

Area Needed: According to the capapcity Groundnut Oil Mill Plant. Hongde SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana.

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Peanut Oil Processing Technology

- Usage: cooking oil refining process

- Production Capacity: 100% cooking oil refining process

- Model Number: Qie

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Certification: CE/BV/ISO9001

- Raw material: Peanut

- Name: cooking oil refining process

- Application: cooking oil refining

- Common capacity: 1-1000TPD

- Character: semi-continuous,fully continuous

- After-sales Service: installation,debugging, training ans service

- Certificate: CE/BV/ISO9001

- Advantage: high oil yield

- Material: stainless steel/carbon stell

After sedimentation, the crude oil is pumped into the frame filter for filtration, and the filtered product oil will be filled and packaged by a filling machine to form superfine fragrant peanut oil products (Fig. 3.9). Download : Download full-size image; Figure 3.9. Flow chart of equipment for superfine fragrant peanut oil production.

Tel: +8619913726068. 中文. Mikim. Professional oil extraction equipment manufacturer. Mikim Machinery is a collection of scientific research, design, manufacturing, installation, commissioning, after-sales service in one of the high-tech enterprise. Our company has been in long-term cooperation with Research Institute of Machine Design.

Peanut Oil Extractor|Groundnut Oil Extraction Machine

- Usage: Peanut Oil, Peanut EDIBLE OIL

- Type: Oil Extraction Machine

- Production Capacity: 50-500kg/h

- Voltage: 115V/220V/380V

- Dimension(L*W*H): 1700*1200*1500cm

- Weight: 780 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Raw material: Peanut

- Product name: Oil Extraction Machine

- Keyword: Peanut Oil Pressing Machine

- Function: Oil Mill Making Pressing Extracting Machine

- Name: Screw Oil Pressing Machine

- Feature: High Oil Yield Efficiency

- Capacity: 1-10 Tons

- Advantage: High Efficient

- Raw materials suitable: Peanut

- After-sales Service Provided: 24 Hours Online Support

The oil extractor has a widely usage and perfect oil pressing effect. It can make peanut oil, groundnut oil, sunflower seed oil, sesame seed oil etc grain oils. Pressed oil light color, nutrient-rich, little damage to the protein, is conducive to the full utilization of oil protein. ·MOQ:set. ·Supply Ability: 200 sets per month.

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- How is peanut oil extracted by mechanical pressing?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

- Voltage: 380V

- Voltage: 220V/380V