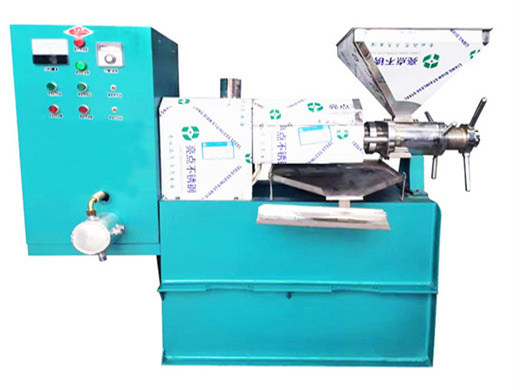

of coconut oil machine crude coconut oil process in lagos

- Usage: Coconut Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 80-5000kg/h

- Voltage: 220V380V

- Dimension(L*W*H): 1.2*0.78*1.1m

- Weight: 300 KG

- Core Components: Motor, Pressure vessel, PLC

- Oil type: Coconut Oil

- item: Coconut and Coconut combined oil press temperature control

- Method to press: : Screw Squeezed Press

- type: oil pressers cold press oil machine

- Raw material: Vegetable Seeds Oil Press Machine

- Application range: kernel oil press machine shell Coconut screw oil press production line

- Function: Coconut and Coconut combined oil press

- Oil cake diameter: : 192mm

- Advantage: High Oilput

- Product name: oil making machine

Hongde 1500. 45 150 Tonnes per 24 Hours. 3-Phase 170 H.P. 5500 MM. 1380 MM. 1980 MM. Are you looking for the most suitable and cost effective Coconut Oil Extraction Machine or Coconut Oil Extraction Plant to start your own Coconut Oil Manufacturing Business, then you are in the right place. Hongde is the best and reliable manufacturer.

for RBD coconut oil and virgin coconut oil are presented in Table 1 (above). Some physical characteristics, typical fatty acid composition and Codex ranges of coconut oil are shown in Table 2 (right). It can be seen that CNO contains about 92% saturated fatty acids; this makes the crude oil very stable against oxidation. However,

A comprehensive review on the techniques for coconut oil

- Usage: Raw Coconut ,Coconut etc

- Type: Hydraulic oil press machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 800*700*1100mm

- Weight: 550 KG

- Core Components: Motor

- Oil type: Coconut Oil

- Raw material: Ripe flax, Suzi,Coconut ,Coconut kernel,Coconut

- Name: Hydraulic oil press machine

- Function: Oil Pressing

- Application: Food Industry and fam

- Capacity: raw Coconut about 750kg/h

- Product name: OiL press

- Advantage: High Oil Yield

- Keyword: Oil Expeller

- Item: Industrial Oil Extractor

- Feature: Hige Oil Press Rate

Virgin coconut oil is a useful substance in our daily life. It contains a high percentage of lauric acid which has many health benefits. The current industry has developed several methods to extract the oil out from the coconut fruit. This review paper aims to highlight several common extraction processes used in modern industries that includes cold extraction, hot extraction, low-pressure.

Processing copra oil. Traditionally, processors feed flaked copra into stacked cooking and drying vessels, which reduce the moisture levels down to about 3 or 4% by weight. Then, dried flakes are crushed in a screw press expeller to separate the copra oil from the solid meal. Containing up to 70% oil by weight, coconuts have the highest oil.

CoCoMaN Coconut Machines

- Usage: Coconut Oil

- Production Capacity: 20-2000T/day

- Model Number: 01

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Certification: CE,ISO

- Commodity: Coconut cooking oil machines

- Area Needed: According to the capapcity

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, Nigeria, Ghana, Papua New Guinea, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico. Ask Us.

coconut oil is more soluble than most. common fats and oils. Chemical composition. Coconut oil contains a high. proportion of glycerides of lower. chain fatty acids (Tables 3, 4 & 5). The oil is.

Copra Oil Mill Machine for 20TPD Coconut Oil Production Plant

- Usage: crude oil refinery, Coconut Oil.ect

- Type: Coconut oil refined machine, 1-200T/D

Production Capacity: 1-200T/D Coconut oil refined machine - Voltage: 380-660V, 380-460V

Power(W): according to the capacity of Coconut oil refined machine - Dimension(L*W*H): 1610x615x1260mm of Coconut oil refined machine

- Weight: 1050 KG of Coconut oil refined machine

Certification: BV, ISO9001 - Item: Coconut oil refined machine

Material: Stainless steel and carbon steel - Crude oil moisture and volatile matter: 0.30%

- Power consumption: 15KWh/T

Steam consumption: 280KG/T (0.8MPa) - Turnkey project: Yes

20TPD Copra Oil Mill Plant in Philippines. This is one of our project in Philippine a medium scale copra oil mill, including 20TPD oil extraction line and 10TPD oil refinery line. The daily capacity is processing 20 tons of copra (desiccated coconut) and get 10 tons of refined coconut oil. It is designed for manufacturing edible coconut oil.

Oil from coconut meats were obtained by heated to 70 °C, 80 °C, 90 °C, 1... View Experimental investigations on the performance of nanoboric acid suspensions in coconut oil during milling.

Crude Coconut Oil Processing Machine

- Type: cotton seed oil pressing machines

- Use: cotton seed oil pressing machines

- Certification: ISO ,CE ,BV

- Model Number: cotton seed oil pressing machines

- Product type: cotton seed oil pressing machines

- Usage: high grade oil

- Voltage: 220/380 OR other

- Residual oil in meal: ≤ 1%

- Production Capacity: 20-2000TPD

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Raw material: Coconut

- Material: Stainless Steel and carbon steel

- Price: Negotiation

Method Machine Works, a Malaysia based private company, established since year 2011, is one of the best known manufacturer and exporter of CoCoMaN coconut processing machines, coconut oil processing machines, coconut husk processing machines and coconut shell processing machines.

Coconut oil may be extracted by adding a mixture of sev-eral types of enzyme mixtures into coconut milk. The first mixture includes Cellules, Temramyl (endoamylase), Vis-cozyme L, neutrase and alcalase (protease) into coconut milk. This method is able to extract good quality coconut oil up to 83% yield [24].

- Is there a low-cost integrated unit machine for coconut oil extraction?

- [Show full abstract] Coconut oil extraction involves several stages and each of these stages require different machine, therefore, the objective of this research work is to develop a low-cost integrated unit machine for the extraction of coconut oil using standard procedures.

- What is the process of low-pressure extraction of coconut oil?

- Figure 2 exemplifies the process of low-pressure extraction. Virgin coconut oil yield with 92.54% was obtained when the centrifugation time was set to 60 min and the centrifugation speed was set to 2700 rpm [ 4 ]. Advantages of this method includes the by-products of this process, such as the coconut shells and husks may be used as fuel.

- What are the challenges faced by the industries in extracting coconut oil?

- Challenges that are faced by the industries in extracting the coconut oil using different methods of extraction are important to be explored so that advancement in the oil extraction technology can be done for efficient downstream processing. This study is vital as it provides insights that could enhance the production of coconut oil.

- How to extract coconut oil from coconut milk?

- Overall process of coconut extraction using low-pressure extraction techniques [ 19] This method consists of a combination of a few separation methods, such as centrifugation and cold pressing. It makes use of the difference in freezing points of the components in coconut milk to extract coconut oil from coconut milk.

- Voltage: 380-660V, 380-460V