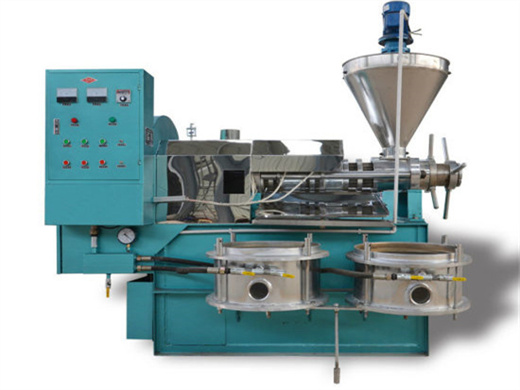

newest peanut oil extraction machine in lesotho

- Usage: Peanut Oil

- Type: For Peanut oil making machine usage

- Production Capacity: 50-3000TPD

- Model Number: JXSE 1212

- Voltage: 380v 440v

- Power(W): As Peanut oil making machine output every day

- Dimension(L*W*H): As your Peanut oil making machine ouput per day

- Weight: Depend on Peanut oil making machine output

- Certification: ISO9001

- Item: Peanut oil making machine

- Material: stainless steel

- Application: for all seeds extraction

- Output: as Peanut oil production machine prices request

- Residual oil in meal: less than 1%

- Solvent consumption: less than 2kg/t

- Power consumption: not more than 15KWh/T

- Process of refining: Degumming ,Decolorization

- Rate of Peanut extraction: 38%- 42 %

- Payment: l/c t/t

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine. Wide range of applications.

Groundnut Oil Manufacturing Process With Flowchart - Hongde

- Usage: Peanut Oil,Peanut

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V customized

- Dimension(L*W*H): 2600*2100*1730mm

- Weight: 1200 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Product name: Oil press machine

- Application: Oil presser

- Advantage: High oil output

- Capacity: 60-450kg/h

- Oil extraction rate: 44%-50%

- Function: Physical Oil Refining

- Material: Stainless Steel SS304/316

- Press type: Hot press and cold press

- After Warranty Service: Video technical support

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

Peanut / Groundnut Oil Extraction Machine Manufacturers and Exporters

- Usage: hydraulic press oil

- Type: Seed Roaster

- Voltage: 220v/380v

- Dimension(L*W*H): 90*100*140

- Weight: 270 KG

- Core Components: Motor

- Oil type: Peanut Oil

- Product name: Hydraulic cold oil press cooking oil press Peanut oil press machine

- Function: Oil Pressing

- Application: Squeeze Oil

- Feature: High Oil Yield Efficiency

- Advantage: Simple Operation

- Used for: Peanut Kernel Peanut Nuts

- MOQ: 1 Set

- Key words: Peanut Processing Oil Machine

Peanut Oil Extraction Machine. Groundnut is a very common oil bearing material, so the technology of extracting peanut oil is relatively mature. Hongde GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs.

Cold Pressing Peanut Oil: Integrated Screw Oil Press Advantages. 1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, peanut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the.

Explore the peanut press machine's role in oil yield | Duyvis

- Usage: Peanut Oil

- Type: Oil Pressing Machine, seabuckthorn oil extraction

Production Capacity: 250-400 kg/h - Voltage: According to customer demand

Power(W): 21 KW - Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

Certification: ISO9001-2008 - Color: White, green

Production Raw material: Peanut - Work principle: Mechanical extruding

- Warranty period: One year

English manual: Yes - Factory visiting: Yes

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

Xuyi machinery (2008) claimed to have developed a screw press for extraction of oil from oil seeds such as peanut, soya beans, olives, sesame and sunflower. The throughput of the machine, extraction efficiency, power required, and the volume of the machine was 500 kg/hr, 32-35%, 15-18 kW, 1850x500x1000 mm respectively.

Production Steps Of Peanut Oil Extraction - Taizy Nut Processing Machinery

- Usage: Wheat and Peanut flour mill

- Type: Wheat and Peanut flour mill

- Production Capacity: 100%

- Voltage: 380V/50Hz/3Phase

- Power(W): 7.5kw

- Dimension(L*W*H): 37*7.5*18.5-87*12*30

- Weight: 10Ton-100Ton

- Certification: SGS.ISO.BV.CE

- Item: Used Flour Mill Machines

- Material: Stainless Steel 304

- Function: Wheat and Peanut flour mill

- Advantage 1: Energy Saving

- Advantage 2: Lower power consumption

- Advantage 3: Zero Pollution

- Feature: High output

- Performance: Excellent

- Processing type: Cleaning-milling-packing

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

First, using organic solvents to extract oil from press peanut cake inside oil extractor, then we can get mixed oil and wet meal. Second, the mixed oil will pass through three evaporators to make solvent inside transform into gas, and organic solvents will be recovered for reuse.

- How to choose the best peanut oil extraction machine?

- What’s more, the amount of slag taken by the oil press has a direct effect on the quality of the oil. Choosing LONGER peanut oil extraction machine is a very good choice. An advanced oil extraction machine, plus the right press, can produce high quality peanut oil.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- Who are the best coconut oil extraction machine manufacturers in India?

- Micro Fab Engineers is the best coconut oil extraction machine manufacturers in India at a reasonable cost. We a team of professionals are working with the latest technology and using a high- grade components to ensure high quality. Are you wondering about the coconut oil manufacturing machine price in India?

- What are the best oil extraction machines in India?

- In India’s best oil extraction machines, a big deceleration box is used for more stable cold press oil extraction. The machine has a positive pressure oil filtration system that removes impurities from crude oil particles. 1. Savaliya Industries SL-801 Cold Press Oil Maker Machine

- Voltage: According to customer demand