new virgin sunflower oil extraction plant in lusaka

- Usage: For cooking oil

- Production Capacity: 20-2000TPD

- Model Number: 008

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): standard

- Weight: standard

- Certification: CE,ISO

- Application: edible oil extraction equipment

- Product name: neem oil extraction machine

- Capacity: 20 to 2000tpd

- Model: YH-ZYJ5

- Raw material: Sunflower Seed

- Color: can be customized

- Function: press Sunflower , Sunflower seeds etc oil

- Advantage: simple operation

- Package: wooden case

- Processing type: Edible Oil

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning.

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Cold-pressed sunflower oil: a hot new product | Farmer's Weekly

- Usage: For Sunflower oil dewaxing equipment usage

- Type: For Sunflower oil dewaxing equipment usage

- Production Capacity: 50-3000TPD

- Model Number: JXSE 472

- Voltage: 380v 440v

- Power(W): As Sunflower oil dewaxing equipment output every day

- Dimension(L*W*H): As oil dewaxing equipment ouput per day

- Weight: Depend on oil dewaxing equipment output

- Certification: ISO9001

- Item: oil dewaxing equipment

- Material: stainless steel

- Application: for all seeds extraction

- Output: as per customer requestment

- Residual oil in meal: less than 1%

- Solvent consumption: less than 2kg/t

- Power consumption: not more than 15KWh/T

- Process of refining: degumming ,decolorization ,deodorization , deacidification ,dewaxing

- Payment: l/c t/t

- Rate of Sunflower extraction: about 18 %

Phone Vergezocht Plant Oils factory manager Franz Homsek on 082 411 6634, or email him at [email protected]. Vergezocht Plant Oils is the first factory in Africa to produce cold-pressed, high-oleic sunflower oil. Sabrina Dean visited the plant in Bloemfontein in the Free State to find out more about Vergezocht’s business plan, which is.

The steps involved in Sunflower Oil Refining Process: Degumming. Neutralization. Water Washing. Vacuum Drying. Bleaching. De-waxing. Deodorisation. The chemical refining stages of Sunflower oil are also similar to other soft oils except dewaxing which is additional as sunflower oil contains wax which will be removed by dewaxing process.

Company - Kernel

- Usage: Sunflower oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 100%

- Model Number: LDC15

- Voltage: 380V/50HZ

- Power(W): 15KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Certification: ISO

- Raw material: Sunflower Seed

- Name: black seed oil press machine

- Color: as your requirment

- Material: carbon steel and stainess steel

- Application: Oil Equipment Product Line

- Advantage: Simple Operation

- Warranty: 12 month

- Feature: Multifunction High Efficient

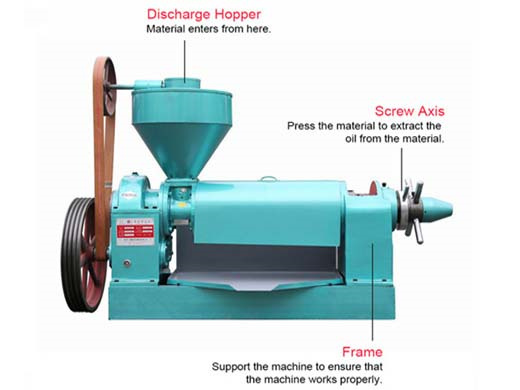

- Character: Screw Oil Pressing Machines

- Use: Extract Essential Oil

Mission. Values. Kernel is the largest producer and exporter of grains in Ukraine, the leader of the world sunflower oil market, and a major supplier of agricultural products from the Black Sea region to international markets. The company accounts for about 8% of the world’s sunflower oil exports. Kernel delivers its products to over 70.

The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL). The agitation rate was kept constant in all experiments, being sufficient to maintain a well-mixed fluid and the particles in suspension.

A Step-by-Step Guide on How Sunflower Oil is Made

- Usage: Sunflower Oil

- Type: solvent extraction

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Model Number: se051

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 1000kg

- Certification: ISO9001

- Product name: Edible oil extraction centrifuge machine on sale

- Application range: Oil -bearing Material

- Advantage: High Efficient

- Function: Oil Production

- Item: Sunflower Oil Extraction Plant

- Use for: Oil Yield

- Section: Meal Extraction

- Product: National Oil Standard

- Quality: Stable Quliaty

Oil refining is a multi-stage process, with the steps involved varying greatly based on the oil in question. When it comes to sunflower oil, the steps that are critical in the production of clear, high quality, and safe edible oil are degumming, alkali neutralisation, bleaching, dewaxing, deodorisation, and an optional winterization process.

1 200 tons/day. Power extraction shop on sunflower processing. Our mission is. To be strong to make others strong too! Oliyar is one of the largest producers of vegetable oil in Ukraine. Striving to increase capacity and improve production, we built a new oil extraction plant in the Stavchany village.

Optimus Agro

- Industrial Use: Food

- Base Material: glass

- Collar Material: glass

- Use: Cookie, Canned Food, Jelly, Milk, Sugar, Sandwich, cake, Bread, Snack, Chocolate, Lollipop, Noodle, Pizza, Chewing Gum, Sunflower OIL, Salad, Sushi, Seasonings & Condiments, CANDY, Baby Food, PET FOOD, POTATO CHIPS, Hamburger, Nuts & Kernels, Other Food

- Cap Material: Tinplate

- Model Number: AZ-2022042201

- Color: Clear

- Shape: round ,oval,cylinder

- Sample: Free

- OEM: Yes

- Print & Logo: Customized

- Usage: yogurt,pudding,honey,ice cream,jam ,caviar, milk shake

- Capacity: 4oz 8oz 12oz 16oz 24oz

- Feature: Eco-friendly, stocked ,water tight,lead-free,food grade,

- Craft: Full-automatic machine

- Keywords: mason cup ,graduated mason jars wide mouth

The Optimus Agro brand brings under its brand PJSC "Zaporozhien oil extraction plant" located in Zaporizhzhya city in order to improve the quality of control of oilseeds. 2015. The Optimus Agro Group is included in the TOP -5 processors of sunflower seeds in the Ukrainian market in terms the installed capacity. 2014.

Andreotti Impianti extraction plant is designed for oil solvent extraction starting from oil seeds flakes or pre-pressed cake. This environmental-friendly extraction system reduce the hexane content in the air emission, where the air is washed with mineral oil and the hexane is absorbed. Absorbed hexane is evaporated and recycled.

- How is sunflower oil extracted?

- Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil.

- Where are seed precleaning and seed drying performed in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed precleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- Can mmmz make sunflower oil more widely available in Zambia?

- The company will buy all sunflower produced by contracted out-growers. MMMZ wants to make sunflower oil more widely available in Zambia through this project. Sunflower oil is more nutritious than other edible oils and if processed from locally produced seed can be sold at prices which are affordable to low-income consumers.

- Does Ukraine export sunflower oil?

- It should be emphasized that Ukraine exports sunflower oil to over than 100 countries of the world, which requires more efficient technologies for its production for the purpose of providing with world demand. For today, there are two methods of extracting oil plant raw materials: press and extraction.