new screw sunflower oil press in rwanda

- Usage: Sunflower oil extraction

- Production Capacity: 10T-3000T/D

- Model Number: Sunflower oil extraction

- Voltage: 220V/380V/440V

- Power(W): Capacity

- Dimension(L*W*H): Sunflower oil extraction According to your request

- Weight: Sunflower oil extraction According to your request

- Certification: ISO9001

- Processing: Batch-type or Semi-continuous

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- ITEM: equipment for the production of Sunflower oil

KEYWORDS: Dehulled sunflower seeds, oil expression, The twin,screw 3-4 mm thick presscake hasto be conditioned at press. 10-12% moisture andflaked to0.2-0.3 mmthickness for further solvent extraction. Final defatted meal of about 28-44% protein content, depending onthe xtent of Industrial extraction of edible oil from oilseeds orother dehulling.

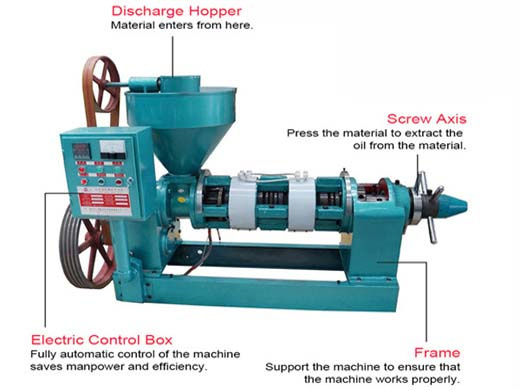

Screw Oil Press - MKOP165. Our oil press machines are capable of processing various types of oil seeds such as hemp, soybean, sunflower, jatropha, neem, flax, cotton, sesame, peanut, linseed, among others. The Meelko oil presses are characterized by having a smooth cover, which gives greater ease of operation and improves the maintenance process.

A new twin-screw press design for oil extraction of dehulled

- Usage: Sunflower oil

- Type: Sunflower

- Production Capacity: Acorrding to your require

- Model Number: Sunflower Oil Press

- Voltage: Sunflower Oil Press is Acorrding to your require

- Power(W): Sunflower Oil Press is Acorrding to your require

- Dimension(L*W*H): Sunflower Oil Extraction Machine is Acorrding to your require

- Weight: Sunflower Oil Extraction Machine is Acorrding to your require

- Certification: ISO9001

- Supplier type: Sunflower oil produce line

- Soften water: 150Kg/T oi

- Refining rate: Refining consumption Less than 1%

- Texture: Mild steel and SS

- Steam consumption: 500Kg per ton

- Solvent consumption: Less than 250g per ton

- Electric consumption: Less than 10kwh per ton

- Bleaching earth consumption: 80-500KG/Toil

- Processing: Oil press ,extraction ,refinery

- Item: Sunflower Oil Extraction Machine

A twin-screw press (screw diameter=136 mm, length/diameter=6.5, screw speed 15?100 rpm, feed rate=50?150 kg/h) was designed with partially intermeshing and counter-rotating screws and was tested on dehulled sunflower seed. The results were compared to a single-screw lab-scale press.

The results were compared to a single-screw lab-scale press. Dehulled sunflower seed (wt, 6.0%; oil, 58.6%) without pretreatments (crushing or cooking) gave 93.6% oil recovery with the twin-screw press, in contrast to 20% oil recovery with the single-screw press. The oil expressed with a twin-screw press had less foreign material than the oil.

A new twin?screw press design for oil extraction of dehulled

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD

- Voltage: 220V/380V/440V/Customer require

- Weight: 1000 KG

- Core Components: Other

- Oil type: Sunflower Oil

- Raw material: Sunflower ,Sunflower oil cake

- Function: Solvent extractor oil cake

- Application: Oil production line

- Capacity: 10-500T/D

- Main equipment: Rotocel extractor

- Feature: To extract oil from oil cake

- Color: As required

- Power(W): As capacity

- Capacity(t/d): 80

A twin-screw oil press can be expected to solve these problems because of the higher transportation force, similar to a gear pump, and better mixing and crushing at the twin-screw interface. A twin-screw press (screw diameter=136 mm, length/diameter=6.5, screw speed 15?100 rpm, feed rate=50?150 kg/h) was designed with partially intermeshing.

This study indicated that 86.08% of dehulled sunflower, 13.92% of wheat bran with 6% sample moisture may be considered for oil expelling of dehulled sunflower at 70°C press head temperature. The oil recovery in two sets of experiments varied from 87.23% (at constant temperature) to 87.71% (at constant moisture). Practical applications. The.

A Twin-screw extruder for oil extraction: I. Direct

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine, Cold&Hot pressing machine

- Production Capacity: 5TPD

- Voltage: 380v

- Dimension(L*W*H): 2000*1600*2700(mm)

- Weight: 1500KG

- Warranty: 1 Year, 1Year

- OIl yield: 98%

- HS Code: 8497200000

- Keyword: Sunflower pressing oil processing machine

- Squeezer speed: 100-130

- Delivery days: 7-15days

- Material: Alloy

- Trade item: FOB

- Certification: ISO

A new process, in which sunflower seeds are pressed in a twin-screw extruder, is examined here. The screw profile was first optimized. Oleic sunflower seeds were crushed and 80% of the oil was.

whole sunflower seeds in a contra-rotating twin-screw press. The expression yield from whole seeds was low (75%) but could be increased to 93.6% if the raw material was dehulled.

Twin-screw extruder for oil processing of sunflower seeds

- Usage: Sunflower Oil, Sunflower EDIBLE OIL

- Type: cooking crude oil refinery equipment

- Production Capacity: 100-500kg/h

- Voltage: 380V/50HZ 3Phases(customize as your local power)

- Dimension(L*W*H): 30*12*6m

- Weight: 2500 KG

- Warranty of core components: More than 5 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gearbox

- Oil type: Sunflower Oil

- Product name: crude edible cooking Oil Refining Machine

- Advantage: Low Residual, Long Service Life, Easy Operation

- Raw material: Vegetable Seed Crude Oil and animal crude oil

- Application: Edible Oil Processing Line, cooking oil factory

- Function: Degumming, Decolorization, Deordorization, Deacidification, Filtration

- Color: Customer Required

- Material: Food Stainless Steel 304 or carbon steel

- After Sales Service: Video technical support, Online support

- Certification: ISO 9001,CE

A new application of twin-screw extruder as a machine to conduct a thermo-mechanical pressing and a solvent extraction of sunflower oil in a single step and in a continuous mode was studied.

Furthermore, an investigation of continuous oil extraction using an extruder divided into two zones, (i) twin-screw zone, which was built from two co-rotating and co-penetrating screws and (ii) double single-screw zone, which was constructed from two co-rotating single-screws, increased oil yield up to 90% with residual oil content in cake meal.