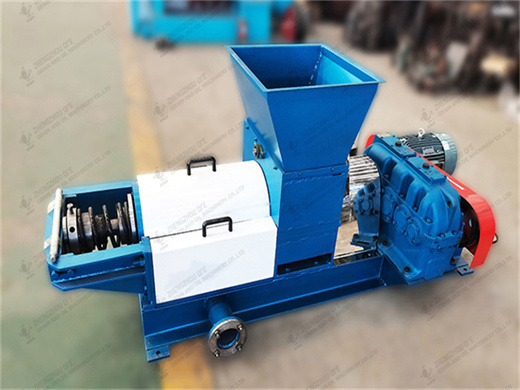

long fiber mattress oil palm fiber extractor in zimbabwe

- Usage: Palm fruit oil extraction plant

- Type: Palm fiber plant

- Production Capacity: 1-2000TPH

- Model Number: DL-ZYJ06

- Voltage: 220V/380V

- Power(W): 18.5KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Equipment name: Palm fruit oil extraction plant

- warranty: 1 year

- material available: Palm fruit oil extraction plant

- texture: stainless steel, carbon steel, alloy steel

- projects done: 1-2000TPD complete oil lines

- markets: America, Europe, Africa, Asia, Australia

- services: engineering, producing ,installation, construction

- Advantage: Energy saving, environment friendly

Abstract. Twenty first century has witnessed remarkable achievements in green technology in material science through the development of biocomposites. Oil palm fiber (OPF) extracted from the empty fruit bunches is proven as a good raw material for biocomposites. The cellulose content of OPF is in the range of 43%?65% and lignin content is in.

Bahari M A M. Oil palm trunk (OPT) as an alternative cellulosic material for brown paper production. Thesis for the Master’s Degree. Pekan Pahang: Universiti Malaysia Pahang, 2010. Google Scholar Koba Y, Ishizaki A. Chemical composition of palm fiber and its feasibility as cellulosic raw material for sugar production.

Palm Dried Long Fiber - Global Green Synergy

- Usage: Palm Oil

- Production Capacity: 3-6KG/hour

- Voltage: 220V/110V

- Dimension(L*W*H): 390*150*292mm

- Weight: 9.5 KG

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Other, Engine

- Product name: Home Oil Pressing Machine

- Function: Making Palm Oil

- Machine: fully stainless steel

- Advantage: Energy Saving

- Keyword: Mini Oil Expeller

- Material: Stainess Steel

GGS Dried Long Fiber (DLF) is dried, long palm fiber produced using proprietary technology of Global Green Synergy Sdn Bhd. DLF is produced from oil palm's vascular bundles in the Empty Fruit Bunch (EFB), which is considered a waste product after the Fresh Fruit Bunch (FFB) has been processed. DLF is 100% natural with premium quality that.

PFs have been extensively involved in NFC studies due to their superior properties, low cost and high availability. Recent works on PNFCs have considered diverse palm types, fiber sizes, matrices, etc., aiming to explore their effects on the overall properties of PNFC materials. Various thermoplastic, thermosetting, ceramic and natural matrices.

Oil palm fiber (OPF) and its composites: A review

- Usage: Palm oil presser machine

- Type: Palm oil presser machine

Production Capacity: 100% - Voltage: 220V/380V/440V

Power(W): 18.5KW/T - Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

After-sales Service Provided: Overseas service center available - Material: Stainless steel

- Engineers request: 1-2 engineers

Oil Grade: 1st,2nd,3rd - Environment friendly: yes

- Business type: manufacturer

- Methods: Palm oil presser machine

- oil rate: 20%-98%

Abstract. Twenty first century has witnessed remarkable achievements in green technology in material science through the development of biocomposites. Oil palm fiber (OPF) extracted from the empty fruit bunches is proven as a good raw material for biocomposites. The cellulose content of OPF is in the range of 43%?65% and lignin content is in.

These properties may result in an undesirable final composite laminate [ [99], [100], [101] ]. OPFs are obtained from oil palm biomass in the form of thread-like bundles. In the post-processing stage, OPF are approximately 10?30 or 50?60 mm long. In general, the average fibre length is 200 μm.

Consortium Develops First Textile Palm Fibers And

- Usage: Palm Oil

- Production Capacity: 98-100%

- Voltage: 380V

- Dimension(L*W*H): 190*145*170cm

- Weight: 600 KG

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: Oil Press Machine Line

- Raw material: Palm, Palm Kernel

- Function: Making Palm Oil

- Application: Palm Oil Production

- After Warranty Service: Video Technical Support Online Support

- Advantage: Energy Saving

- Feature: High Oil Yield Efficiency

- Keyword: Oil Press Machine

- Color: Silver

- Capacity: 400kg/h

August 4, 2020. CAIRO — July 31, 2020 — A consortium of five Egyptian researchers have developed the world’s first high performance fibers and reinforcements extracted from the byproducts of pruning of date palms, such as frond and fruit stalks. PalmFil fiber is not only sustainable, but also economical in manufacturing, compatible with.

It is estimated that worldwide generation of oil palm fibers would be 149 million ton in 2020, which is twofold of a total mass of extracted palm oil . Moreover, the OPF which contains 48 to 65% cellulose has specific modulus and high specific strength comparable to glass fibers [ 13 , 14 , 15 ].

Oil palm fibers: Morphology, chemical composition, surface

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Oil Extraction Machine

- Production Capacity: 200kg/h-2000kg/h

- Voltage: 380v

- Dimension(L*W*H): 2650*1900*2700mm

- Weight: 1900 KG

- Core Components: Motor, Bearing, Gearbox

- Oil type: Palm Oil

- Product name: Cooking cold screw oil making machine for Palm

- Raw material: Palm Palm Black

- Feature: High Oil Yield Efficiency

- Advantage: Three-stage press

- Processing Types: Cold/hot pressing machine

- Application range: Kinds s

- HS Code: 8479200000

- Dimension (mm): 2650*1900*2700

- After Warranty Service: Video technical support

Oil palm fiber is an important lignocellulosic raw material for the preparation of cost-effective and environment-friendly composite materials. The morphology and properties of these fibers have been analyzed. The properties of two important types of fibers, the oil palm empty fruit bunch fiber and the oil palm mesocarp fiber (fruit fiber) have been described. The surface topology of the.

The effect of coupling agents on the mechanical and physical properties of oil palm empty fruit bunch?polypropylene composites. H. Rozman C. Lai H. Ismail Z. Ishak. Materials Science, Engineering. 2000. Oil palm empty fruit bunch?polypropylene (EFB-PP) composites have been produced using a twin-screw extruder as the compounding equipment.

- What is oil palm fiber?

- The term oil palm fiber is used in place of oil palm empty fruit bunch fiber throughout this paper for convenience. 2. Oil palm fiber 2.1. Extraction Oil palm fiber (OPF) is extracted from EFB by retting process.

- Is oil palm fiber a good raw material for biocomposites?

- Twenty first century has witnessed remarkable achievements in green technology in material science through the development of biocomposites. Oil palm fiber (OPF) extracted from the empty fruit bunches is proven as a good raw material for biocomposites.

- What is the tensile strength of oil palm fiber-PF composite?

- Effect of fiber treatments Oil palm fiber-PF composite exhibited maximum tensile strength of 40 MPa, tensile modulus of 1.3 GPa and elongation at break of 9% when the fibers were treated, respectively, with permanganate, mercerization and latex coating ( Sreekala et al., 2000 ).

- Is EFB a good fiber source for oil palm trees?

- Among the various fiber sources in an oil palm tree, EFB has potential to yield up to 73% fibers ( Wirjosentono et al., 2004) and hence it is preferable in terms of availability and cost ( Rozman et al., 2000 ). Palm oil industry has to dispose about 1.1 ton of EFB per every ton of oil produced ( Karina et al., 2008 ).

- Voltage: 220V/380V/440V