in peanuts oil extraction equipment in botswana

- Press Series: Second

- Customized: Customized

- Production Name: Cold Oil Press Machine

- Press Automatic Grade: Automatic

- Material: Carbon Steel Q235

- Function: Making Edible Oil

- Power(W): 1.5kw

- Color: Clients′ Requirements

- Certification: CE ISO

- Transport Package: Plywood

- Specification: depend on different model

- Production Capacity: 10000

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

A Complete Guide to Peanut Oil Production - Anderson

- Usage: Peanut Oil

- Type: Peanut oil hexane solvent extraction

- Production Capacity: 100T~250T/D

- Model Number: GQ-0429

- Voltage: 220V/380V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: ISO9001

- Item: Peanut oil hexane solvent extraction

- Steam consumption: ≤280Kg/T

- Business type: manufacture

- Solvent residual: < 0.07%

- Market: all over the world

- Index in crude oil: 50-500ppm

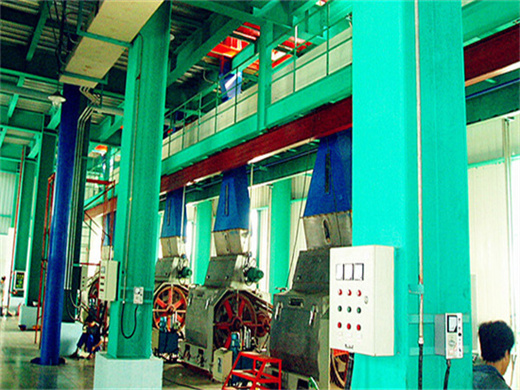

- Main equipment: rotocel extractor, desolventizer, distiller, condenser

- Material: Stainless steel and carbon steel

- Extracting method: Solvent extraction method

What’s Inside the eBook. In this guide to peanut oil, we’ll examine the history of peanut production, explain how peanuts are processed into oil, and discover peanut oil’s diverse product applications as we explore this market’s global growth potential. The upstream processes of harvesting, cleaning, drying, and storing peanuts are.

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. Mechanical techniques for oil extraction from peanuts are.

Peanut processing [en] - CTCN

- Usage: oil refinery manufacturer

- Type: oil refinery manufacturer

- Production Capacity: 1-500T/D

- Model Number: QM21

- Voltage: 380V-415V

- Power(W): depend on the mode of the Peanut Oil Machine

- Dimension(L*W*H): depend on the mode of the Peanut Oil Machine

- Weight: depend on the mode of the Peanut Oil Machine

- Certification: CE, BV,ISO9001

- item: oil refinery manufacturer

- production process: pretreatment,extraction,refining

- Raw material: Peanut

- Waste Bleaching Earth Oil Content: 25% to 35 %

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 80-500KG/T Oil

- Supplier Type: oil refinery manufacturer

- Steel material: Stainless Or carbon steel

The peanuts are prepared for the oil extraction process by being shelled and cleaned. Oil production requires some type of press with which to extract the oil form the groundnuts and filtering equipment. Practical Action has developed a simple manual screw press that would be suitable for extracting oil from peanuts, as well as many other.

The first two steps—cleaning and shelling—happen before the peanuts arrive at the oil mill. Inside the peanut oil extraction plant, roller mills crack the peanut kernels into smaller pieces to increase the surface area for conditioning and pressing. This also removes the peanut skins, which can be blown off with an air separator.

Defatting and Defatted Peanuts: A Critical Review on

- Usage: Peanut Oil

- Type: Vegetable Seed Oil Machine

- Production Capacity: 100TPD Peanut oil machine

- Model Number: Peanut oil production companies in malaysia

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales Service Provided: Overseas service center available

- Keywords: Peanut oil production companies in malaysia

- Name: Peanut oil machine

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Peanut oil press machine

- oil rate: 20%-98%

In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting.

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated.

Peanut Oil Processing Technology

- Usage: jatropha Peanut sacha inchi

- Type: Oil Extraction Machine

- Production Capacity: 1t/day-1t/hour-100%

- Model Number: RD-1685

- Voltage: 380V/50HZ

- Power: 5.5kw

- Dimension(L*W*H): 205*169*180cm

- Weight: 620kg

- CCC

- Raw material: Peanut hazelnut Peanut

- Application: cold press oil machine

- Material: Stainless Steel 304

- Capacity: Mini

- Function: cold press oil seed machine

- Product name: blackseed oil extraction machine

- Advantage: Energy Saving

- Color: Clients' Requirements

- Name: neem oil extraction machine

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. The defatted peanut meal contains a high protein level (> 25%) and can be processed into various food products. The objective of this chapter is to introduce the compounds available and the health benefits of cold.

Abstract. Supercritical carbon dioxide (SC CO 2) extraction of oil from peanuts is an alternative to hexane extraction or the mechanical oil press. Oil was successfully extracted using SC CO 2 at temperatures of 25?120°C and pressures of 140?690 bar. Pressure, temperature, and extraction vessel orientation affected the extraction of oil.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What methods are used to extract peanut oil?

- This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques. Their primary goals are to maximize oil extraction and unlock the untapped potential of defatted whole peanuts.

- What is peanut pretreatment technology?

- Pretreatment Technology Peanut pretreatment refers to a series of treatment processes before oil production, such as cleaning, shelling, grading and selection, drying, cooling, thermal conditioning, pressing, and cooking.