how to extract oil from palm kernel plant in zimbabwe

- CAS No.: DFS123456

- Other Names: Scented Oil

- EINECS No.: DFS123456

- FEMA No.: DFS123456

- Type: Natural Flavour & Fragrances

- Usage: Daily Flavor, Industrial Flavor, Flavor for Scent diffuser

- Purity: 100%, 99.9%, Compound

- Natural Variety: Plant Extract

- Model Number: DFS123456

- Product name: Fragrance Oil

- Use: fresh air

- Natural Variety: Plant Extract

- Material: Floral & Fruit

- Capacity: 200ml, 500ml, 1L , 5L,25kg

- Application: Hotel, Office, Casino

- Feature: Eco-friendly Paper Air Freshener

- Logo: Accept Printing OEM Logos

- Appearance: Liquid

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

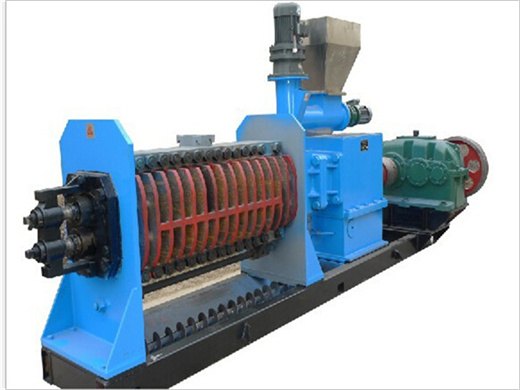

The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing. Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing.

[Beginners Guide] How To Process Palm Kernel Oil - Agrolearner

- Usage: Palm OIL, Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 45 kg

- Voltage: 220-240 volt

- Dimension(L*W*H): 40*94*67

- Weight: 80 KG

- Oil type: Palm Oil

- Gear Box: Helical Shaft Gear

- Energy Consumption: 400 - 1500 Watt/Hour

- Motor Power: 1,5 kW

- After Warranty Service: Spare parts

The cooked palm kernels are then fed into a screw press machine, which uses a rotating screw to apply pressure and extract the oil. The oil is squeezed out of the kernels and collected in a container. Step 2. Clarification. The extracted oil is then passed through a clarifier to remove any solids or impurities.

2. extracting by screw oil presses: Put the well prepared palm kernel meal to the feeder of the screw oil press and start extracting oil! The meal is forced through the barrel by the action of the revolving worms. The volume axially displaced by the worm diminishes from the feeding end to the discharge end, thus compressing the meal as it.

Harvesting Nature's Bounty: How to Extract Palm Kernel Oil?

- Usage: Palm Oil

- Production Capacity: 1.3TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1180*405*1120

- Weight: 195 KG

- Machinery Test Report: Not Available

- Video outgoing-inspection: Not Available

- Warranty of core components: 1 Year

- Core Components: Motor, Gear

- Product name: YZYX70 Vegetable Oil Pressers Mini Oil Press Price

- Color: Can be customized

- Capacity: 50kgs/h

- Raw material: Palm, Palm Kernel

- oil content of dry cakes: <=7.8%

- spiral axes rotate speed(r/min): 33-42

- Advantage: Simple Operation/high efficiency

- Application: Screw Oil Expeller

- Material: Carbon Steel Q235

- Company character: manufacturer with export right

- After Warranty Service: Video technical support, Spare parts

- Local Service Location: None

- After-sales Service Provided: Free spare parts, Video technical support

- Certification: ISO9001:2008;SGS;TUV

The expeller applies mechanical pressure to squeeze the oil out of the palm kernels. This process separates the oil from the solids, resulting in crude palm kernel oil. 7. Filtration: The crude palm kernel oil is often filtered to remove impurities and solid particles. Filtration can be done using filter presses or other filtration equipment.

While palm oil is extracted from the fleshy fruit, palm kernel oil is obtained from the inner kernel of the oil palm fruit. Together, they contribute to the global palm oil production, meeting the demand for vegetable oil worldwide. The production of palm kernel oil involves further processing steps to extract the oil from the kernels.

3. PALM OIL PROCESSING - Food and Agriculture Organization

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V/220V or as required

- Dimension(L*W*H): 800*650*1100

- Weight: 530 KG

- Warranty of core components: 5 years

- Core Components: Motor

- Certification: CE, ISO

- Function: Making Palm Oil

- Capacity: 45-150kg/h

- Advantage: Energy Saving Low Residual

- Application range: Dry Oil Seed

- Material: 304 Stainless Steel

- Processing Types: Hydraulic Press

- Feature: High Oil Yield Efficiency

- Application: Palm Oil Press

- Product name: Reasonable price Palm oil press for sale /oil mill

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a.

The raw palm kernel nut is an oil yielding seed which contains between 40% to 55%. of oil, 55% to 40% of cake and 5% of sludge. The raw kernel nuts are bought from the village markets and transported to the factory. On arrival, the bags of kernel nuts are measured and packed ready for processing.

[Beginners Guide] How To Process Palm Oil

- Usage: edible oil, all kinds of vegetable s

- Type: Palm oil press machine

- Production Capacity: Palm oil press machine

- Model Number: Palm oil press machine, oil fractionation

- Voltage: depend on the capacity, depend on the capacity

- Power(W): depend on the capacity, depend on the capacity

- Dimension(L*W*H): depend on the capacity, depend on the capacity

- Weight: depend on the capacity

- Steam consumption: based on Palm oil press machine

- Color: based on Palm oil press machine

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

To process palm oil, begin by harvesting fresh palm fruit bunches and separating the fruit from the bunches. Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil.

2.1.2 Extraction Step: The process consists of just four major units. 1) Extraction 2) Desolventizing 3) Distillation 4) Solvent recovery In the extractor, the fresh hexane will be pumped into.

- How many ways to extract Palm kernel oil?

- There are two common methods of extracting palm kernel oil, one is full press extraction where mechanical screw oil press machines are used to extract oil out by squeezing under high pressure, this oil extracting method is mainly used by small and big capacity oil mill plants.

- What is palm kernel oil extraction process?

- PALM KERNEL OIL EXTRACTION Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extraction of palm kernel oil.

- How is palm oil extracted?

- Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil.

- How is oil extracted from the kernel?

- The oil extraction from the kernel is achieved by different methods () under different settings, with emphasis on the cost and safety aspects. The principal methods include screw pressing, solvent extraction, and a combination of the former and the latter (screw pressing followed by solvent extraction).