high yield sunflower oil extraction plant overview in nepal

- Usage: All kinds of oil seed

- Production Capacity: 200-300KG / H

- Model Number: automatic hydraulic oil press machine

- Voltage: 220V, 380V, or other, 220v/other

- Power(W): 11000

- Dimension(L*W*H): 900*750*1400

- Weight: 880kg

- Certification: CE& BV

- After-sales Service Provided: No overseas service provided

- Product type: automatic hydraulic oil press machine

- Raw material: Sunflower Seed

- Application: oil press

- Warranty: One Year

- Feature: High Output

- Advantage: dual pressure

- Material: Carbon Steel Stainless Steel

- Character: cold and hot press

- Price: Negotiable

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting medium pressure on.

Abstract. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed.

Pulsed electric field assisted sunflower oil pilot production

- Usage: Sunflower Oil

- Type: Cold & Hot Pressing Machine

Production Capacity: 150-250kg/h - Voltage: 220V,380V

Power(W): 3KW - Dimension(L*W*H): 1950x1300x1900

- Certification: BV , ISO9001-2000

Screw speed: 30-40 r/min - Vacuum pump: Y90S-4-1.1KW

Gear ratio: 15/40x15/55=1 - Heater: 3Kw

- Package: wooden cases

type: automatic electric smal Cold&Hot crew oil press - Authentication: ISO9001-2000

The initial RSSC conductivity was 0.12 mS/cm. To analyze PEF treatment effect on oil extraction firstly the most effective solvent was selected from industrially applied n-hexane, petroleum ether and ethanol. Fig. 3 shows the extraction yields obtained in the sunflower oil extraction using three solvents.

1. Introduction. In comparison with other vegetable oils in recent years, the world production of sunflower oil has increased significantly (Luciana & Petrella, 2014).Due to high nutritional value and valuable chemical composition, sunflower oil is largely used for human consumption both in Russia and in many European countries, India and Turkey and considered to be a great source of proteins.

Extracting and refining steps of sunflower oil. | Download

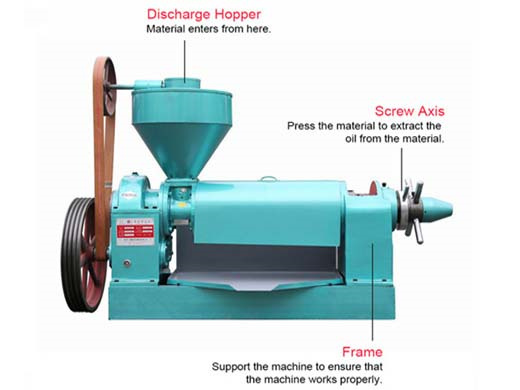

- Usage: Screw Sunflower Oil Press

- Type: Oil Pressing Machine

Production Capacity: 98%-100% - Voltage: 380

Power(W): 5.5KW~15KW - Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

Certification: CE ISO - Capacity of cold pressed Sunflower oil: 35kg-400kg/h

Material of cold pressed Sunflower oil: Stainless Steel SS304/316 - Residual oil rate: 5~7%

- Raw material: Sunflower Seed

- Warranty period: 12 months

- Application range: Oil Production Line

Feature of cold pressed Sunflower oil: High Oil Yield Efficiency - Function of cold pressed Sunflower oil: Produce High

- Character: Screw Oil Pressing Machines

Figure 1 represents schematically the main steps of sunflower oil extraction and refining. ... High Oleic Sunflower Oil ... C increased the oil output; however, a maximum oil yield of 48.869 ± 6..

The sunflower seed pressing procedure manages to transform about 25?33% of the initial seed weight into oil , while in chemical extraction, the average extracted oil yield is ~42% . As a result of this process, byproducts are generated with a high concentration of nutritional components, including high protein content, reaching around 40?50.

Pulsed electric field assisted sunflower oil pilot production

- Core Components: Other

- Type: thresher, Combined Rice Milling

- Use: Sunflower thresher

- Production Capacity: 10TPD

- Voltage: 380v

- Dimension(L*W*H): 2150*1520*1430(mm)

- Weight: 150 KG

- Product name: Rice Machine Complete

- Application: rice, millet

- Color: customize

- Function: Grain Shell

- Usage: Rice Polisher Whitener

- Capacity: 150kg/hr

- Feature: Easy Operation

- Model: TAXING

Sunflower oil pilot-production based on local raw materials assisted by pulsed electric field (PEF), which is produced in terms of oil yield, extraction kinetics and chemical parameters on pilot.

The application of pulsed electric field (PEF) as one of the nonthermal intensification methods has been proposed to increase oil yield extraction from sunflower seeds. PEF treatments have been carried out under various electrical parameters such as electric field, pulsed frequency, pulse width, time of treatment and sample conductivity. 55 fractional factorial design has been used for the.

Sunflower oil from enzymatic aqueous extraction process

- Usage: Sunflower Oil

- Production Capacity: 5T/D

- Model Number: 6YL

- Voltage: 380V

- Power(W): 5.5~11kw

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Certification: CE ISO

- Name: Screw Sunflower Oil Press Machine

- Advantage: lowest residual oil rates

- Warranty: 1year

- Raw material: Sunflower Seed

- Application: Oil Production Line

- Product name: Oli Press

- Model: 6YL

- Port: qingdao/tianjin/dalian

- Function: Cold/Hot Press

- Origin: Henan China

In this article, the enzymatic aqueous extraction (EAE) of sunflower seed oil was investigated. The effects of the operational variables (temperature, water seed mass ratio, and enzyme concentration) were evaluated in order to define the conditions that maximize the free oil yield (FOY).

The oil yield was found to increase by 9.1% after treatment of sunflower seeds by variation of PEF parameters: 30 s under an electric field of 7.0 kV/cm having frequency of 15 Hz, solvent content of 40 wt% and pulse width of 30 μs.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- How to optimize oil extraction from high oleic sunflower seeds?

- In this study, response surface methodology (RSM) was applied, to optimize oil extraction from high oleic sunflower seeds via EAEP in a prototype automatic continuous stirred-tank extractor. Temperature, enzyme mass, water mass and proton concentration were varied for the exploration of optimum process conditions.

- What is sunflower seed processing?

- Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons ( FAO, 2013 ).

- Which plant oil is used in sunflower seed production?

- Other plant oil comprises coconut ( Cocos nucifera ), cottonseed ( Gossypium L.), groundnut ( Arachis hypogaea ), lineseed ( Linum usitatissimum ), maize ( Zea mays ), olive ( Olea europaea ), safflower ( Carthamus tinctorius) and sesame ( Sesamum indicum) oil. b World sunflower seed production from 1961 to 2014.

- Voltage: 380

- Voltage: 220V,380V