high quality palm kernel oil reining plant in togo

- Type: Screw

- Configuration: Stationary

- Power Source: AC POWER

- Lubrication Style: Lubricated

- Mute: Yes

- Voltage: 380V/3Phase/50HZ

- Dimension(L*W*H): 1380 x 850 x 1170mm

- Weight: 600KG

- Working Pressure: 7 bar, 8 bar, 13 bar, 6 bar, 12 bar, 10 bar

- Warranty of core components: 2 years

- Core Components: PLC, Engine, Gear, Motor, Bearing, Gearbox

- Gas Type: Air

- Product name: 2019 New Type Air Jet Loom 136cfm 102psi Portable Screw Air Compressor

- Working pressure: 7-13Bar

- Capacity: 3.8m/min(136CFM)

- Motor power: 22Kw (30Hp)

- Cooling method: Air Cooling water cooling

- Usage: Industrial Use

- MOQ: 1 Set

- Brand: Mikovs

- Noise: 73dB(A)

Pacific Palmindo Industri (PALMINDO) is actively producing best quality edible oil products from incoming raw materials of Crude Palm Oil (CPO) and Crude Palm Kernel Oil (CPKO). Both CPO and CPKO are refined, bleached, deodorized and the product RBDPO is further fractionated for human consumption; conforming to the demands of the highest.

The process begins with heating crude palm oil (CPO) to a specific temperature, typically around 70-75°C (158-167°F). This heating reduces the viscosity of the oil, making it more fluid and easier to work with. Crystallization: After heating, the CPO is gradually cooled down under controlled conditions.

Palm oil: Processing, characterization and utilization in the

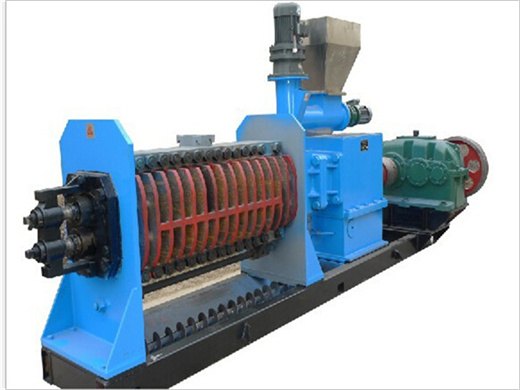

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 15 TONS /DAY

- Voltage: 20 hp

- Dimension(L*W*H): 2261MM*686MM*1423MM

- Weight: 1500 KG

- Warranty of core components: 5 years

- Core Components: Gear, Bearing, Gearbox

- Oil type: Palm Oil

- Extraction of Oils: Palm Oil

- MOTOR: 40 HP

- CAPACITY: 15 Tons/Day

- After Warranty Service: Spare parts

- Certification: ISO 9001-2008

The quality of palm oil dictates and directs its use. Broadly speaking, high quality palm oils are used in the edible oil industry while lower quality oils are used in the non-edible industry for biofuels, candles, cosmetics and soap (Henson, 2012). Good quality oil contains more than 95% neutral TAGs and 0.5% or less FFA.

The refining of crude palm kernel oil is converting it to quality edible oil renewing objectionable impurities to the desired levels in the most efficient manner where possible, losses in the desirable components are kept minimal. After refining of crude palm kernel oil, a good quality has low

Palm Kernel Oil Refinery

- Usage: Making edible oil

- Production Capacity: 5TPD

- Voltage: 380V

- Dimension(L*W*H): 2650*1900*2700mm

- Weight: 1900kg, 1900kg

- Machinery Test Report: Yes

- Video outgoing-inspection: Yes

- Core Components: Motor, Gear, Bearing, Gearbox, Squeezer

- Name: Automatic cold hot cooking oil pressing edible oil press machine

- Used for: Cold & Hot pressing

- Range of usage: Kinds of oil s

- Vacuum power: 2.2KW

- Squeezer speed: 60-100RPM

- Oil cake thickness: 2mm

- Service life: 10 years

- Keyword: Hot cold Palm oil presser Palm machine oil processing

- Packing: Wooden case/ Customized

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India, Colombia

- Certification: ISO CE

Tinytech Palm Kernel Oil Refinery Plant is specially designed and built for processing the Palm Kernel Oil. As you know, palm kernel oil is also referred to as PKO. This oil is obtained from the kernel seeds of the oil palm fruit. The process of extracting the palm kernel oil is through mechanical pressing. The output of seed extraction is the.

The oil palm (Elaeis guineensis), generally known as the most productive oil bearing crop, the source of two important edible oils, i.e. palm oil (PO) from the mesocarp and palm kernel and also produces high quality and versatile oils (Balasundram et al., 2005; Mukherjee and Mitra, 2009; Zou et al., 2012; Kushairi et al., 2017). In 2017, palm.

Palm Oil and Palm Kernel Oil Refining and Fractionation

- Usage: Palm Oil

- Production Capacity: More than 95%

- Voltage: 220V/110V

- Dimension(L*W*H): 45*21.5*24cm

- Weight: 10 KG

- Marketing Type: Other

- Machinery Test Report: Not Available

- Warranty of core components: 1 Year

- Core Components: Gearbox, Motor, PLC

- Product: oil press machine

- Control mode:: automatic working

- Machine Name: Palm oil making machine

- Production: 3-5 kg/h

- Press type: Hot&cold pressing

- Advantage: adjustable temperature

- Material: stainless steel screw and chamber

- Package: Export standard carton

- Use for: Rap seed,Palm meat, Palm meat

The acidity of crude palm kernel oil can vary, depending on quality, from 2.0 to 6.0%. Poor crude palm kernel oil may show 1.0R/10Y (Lovibond 1″) while good crude palm kernel oil may be no more than 0.4R/4Y (Lovibond 1″); this depends largely upon the way the kernels have been pressed and extracted, shipped, and stored (Patterson, 1992).

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

Palm Kernel Oil Refining - Palm Oil Plant

- Model NO.: LBZY-130

- Customized: Customized

- Model: Lbzy-130

- Overall Dimensions(mm): 2100*1500*1800

- Diameter of Squeezing Worms(mm): 130

- Speed of Squeezing Worms(R/Min): 36

- Main Eegine Configuration Power(Kw): 6

- Heater(Kw): 5

- Handling Capacity(Kg/H): 260-400

- Weight(Kg): 1280

- Raw Materials: Palm, Soya, Palm

- Color: Customer′ S Requirement

- Package: International Standard Wooden Box Packing

- Transport Package: International Standard Wooden Box Packing

- Specification: Weight: 1800kg

- Production Capacity: 50 Sets/Month

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical.

UniFuji is a 50/50 joint venture between United Plantations (UP) and Fuji Oil Ltd. On a well-managed plantation of 18.000 ha in Malaysia owned by UP, Unifuji has built a new refinery and fractionation plant that produces high quality, fully traceable and sustainable palm oil fractions. Read more on About Us | Unifuji

- What palm products does Okomu produce?

- Okomu produces the following palm products in a sustainable manner: Crude Palm Oil (CPO) is naturally reddish in color as it contains high amounts of beta-carotene. Palm Kernel (PK) is the seed of the oil palm fruit. Palm Kernel Oil (PKO) is extracted from the seeds (nuts) of the oil palm.

- Is palm olein tainted in Nigeria?

- Presently, crude palm oil is imported for refining in Nigeria, although some quantities of refined bleached and deodorized palm olein are being disguised as crude palm oil and acid oils. Sometimes RBD palm olein is tainted with about 0.03% of crude palm olein and imported into the country as crude palm oil.

- What type of refining process is used for palm kernel oil?

- Imo State, mostly use complete fractional process (85%) in refining palm kernel oil. About 10% use zero refining method while 5% of the processors use incomplete fractional process. Plastic containers and metal drums are dominantly used in most areas in southeast Nigeria for the storage of palm kernel oil. Content may be subject to copyright.

- Does palm oil produce pericarp & kernel oil?

- The palm oil fruit can yield two distinct edible oil ? the pericarp and the kernel parts of the palm fruit. The physical refining process is suitable for both crude palm oil and palm kernel oil. Our physical refining plants are built for large-scale production.