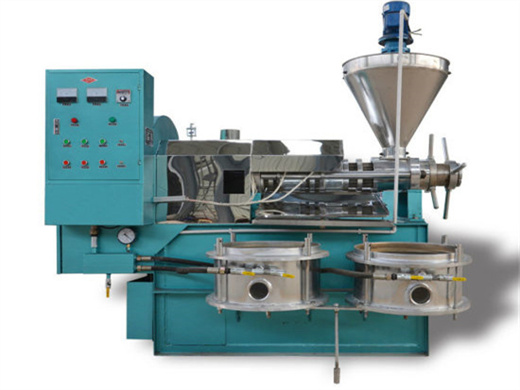

high production peanut oil extraction machine in lagos

- Usage: Peanut oil screw press, oil processing

- Type: Cold & Hot Pressing Machine, Peanut oil screw press

- Production Capacity: 100% Peanut oil screw press

- Model Number: 217

- Voltage: Local Voltage

- Power(W): Depend

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 30tons

- Certification: CE ISO

- Function: Automatic

- capacity: 10-1000tpd

- Quantity: according to the capacity

- Warranty: 1 Year

- Color: Accoring

- Material: Steel

- Advantage: High Oilput

Production Line Process. 1. Cold-Pressed Peanut Oil. First, the sheller is used to shell the peanuts, and then the peanut kernels are transported to be dried in the low-temperature drying oven after being subjected to precleaning, cleaning by the gravity/magnetic separation destoner, and grading.

2 Chemical Composition and Bioactive Compounds of Extracts from Peanut Oil-Processing By-Products. The edible kernel comprised about 68?72% of the peanut, while the balance 28?32% is the peanut hull [ 8 ]. Peanut kernel’s average thickness, width, and length are 6.9 mm, 3.6 mm, and 8.5 mm, respectively [ 9 ].

Random Surface Methodology: Process Optimization for Peanut Oil Extraction in A Mechanical Oil Expeller - ResearchGate

- Usage: Peanut Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 98%-100%

- Model Number: 20

- Voltage: 220V/380V/440V

- Power(W): 15KW

- Dimension(L*W*H): 6000*700*5600mm

- Weight: 3000KG, 1-30Tons

- Certification: ISO9001/CE/BV

- Raw material: Peanut

- Name: Peanut oil mill Indonesia

- Warranty: One Year

- Character: Oil Processing Line

- Advantage: Energy Saving

- Common capacity(TPD): 1-100TLD

- Material: Stainless Steel

- Certificate: ISO9001/CE/BV

- Export market: Global

Peanut seed are approximately 50 % oil of which >80 % is either oleic or linoleic acid. The oleic/linoleic acid (O/L) ratio largely influences oxidative stability and hence peanut shelf.

Due to the rich digestible proteins, the crop is considered as 'king' of oil crops which is being produced from edible seeds and sometimes is referred to as Arachis oil and peanut oil (Aluyor.

Production Steps Of Peanut Oil Extraction - Taizy Nut Processing Machinery

- Usage: Peanut oil solvent extract machine

- Type: Oil Pressing Machine

Production Capacity: 300TPD - Voltage: 380V, 380V

Power(W): 100kw - Dimension(L*W*H): 2.5*3.5*3.5 m

- Weight: 10T

Certification: ISO CE SGS - Application: Peanut oil solvent extract machine

Capacity: 30-1000TPD - Area needed: depend on capacity

- Payment terms: TT LC

Delivery time: 60 days after deposit - Warranty: 12 month

- Installation and debugging: Engineer can go to your country help and teach

Installation time: 40 days - Debugging time: 15 days

Production steps of peanut oil extraction. Peanut Shelling Machine. 1, Oil extraction of peanuts first to go through the shell, select the sprouted and bad, before pressing peanuts can manually peel off peanut shells, but this is more time-consuming, generally only when the amount of family oil extraction is small, only in advance of shelling.

The peanut oil press machine provided by ABC Machinery has high quality and good production efficiency. Its capacity is 5-200ton/d per set. So whatever production capacity you need, it can meet your demand. In addition, we are a leading oil extraction machine.

Groundnut Manufacturing Equipment in Nigeria for sale Price

- Usage: Peanut Oil

- Type: Peanut Oil Processing Plants

- , Automatic

- Production Capacity: 100%, 5T-200T per hour

- Model Number: Peanut Oil Processing Plants

- Voltage: 380V/50HZ, 380V /440V or the local voltage

- Power(W): 15KW, According to the capacity

- Dimension(L*W*H): 1700*1100*1600mm, According to the capacity

- Weight: 1200kg, According to the capacity

- Certification: ISO

- Keyword: Peanut oil processing machine

- Supplier type: Factory(more than 35 years experience)

- Capacity: 5T-200T per hour

Extractor for palm oil, groundnut oil etc in 3 sizes. 1,350,000. Groundnut Coating Machine. Groundnut coating machine of various types. 300,000. Oil Extractor Machine. Oil extracting machine for production of groundnut oil, capable of extracting from food materials... ENTERPRISE. 1,000,000.

The 6YL-100A peanut oil extraction machine is a highly efficient and versatile machine for oil extraction. Its outstanding features, including high oil extraction rate, simple structure, ease of operation, and durability, make it an ideal machine for small-scale oil extraction plants and farmers who wish to process their own oil.

Peanut processing [en] - CTCN

- Usage: purple perilla oil

- Type: Cooking Oil Press Machine

- Production Capacity: 30-500kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 1400*860*1260mm

- Weight: 280 KG

- Warranty: 1 Year, 12 Months

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Peanut Oil

- Raw material: Oil Seeds

- Name: oil pressers

- Material: carton steel

- Advantage: Simple Operation

- Application: Oil Production Line

- Function: Oil Production

- Color: Based on the customer's need

- Quality: Top Level

- After Warranty Service: Video technical support

Peanut butter. The peanuts are first shelled and cleaned. They are then roasted at 425°F (218°C) for 40-60 minutes either a) on trays in an oven, the nuts being turned by hand from time to time or b) in equipment similar to that used for roasting coffee.

Xuyi machinery (2008) claimed to have developed a screw press for extraction of oil from oil seeds such as peanut, soya beans, olives, sesame and sunflower. The throughput of the machine, extraction efficiency, power required, and the volume of the machine was 500 kg/hr, 32-35%, 15-18 kW, 1850x500x1000 mm respectively.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.

- What equipment is used for cold pressing of peanut oil?

- Flow chart of equipment for cold pressing of peanut oil. 2. First, a sheller is used to shell the peanuts, and then the peanut kernels are transported to the low-temperature drying oven to be dried after being subjected to precleaning, gravity/magnetic separation de-stoner cleaning, and grading.

- Voltage: 380V, 380V